System and Method for Rapid Isothermal Gas Expansion and Compression for Energy Storage

a technology of isothermal gas and energy storage, applied in the direction of electrical storage system, fluid coupling, servomotor, etc., can solve the problem of system capital cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]In the following, various embodiments of the present invention are generally described with reference to a single hydraulic cylinder (for example, an accumulator or an intensifier) and simplified valve arrangements. It is, however, to be understood that the present invention can include any number and combination of accumulators, intensifiers, and valve arrangements. In addition, any dimensional values given are exemplary only, as the systems according to the invention are scalable and customizable to suit a particular application. Furthermore, the terms pneumatic, gas, and air are used interchangeably and the terms hydraulic and fluid are also used interchangeably.

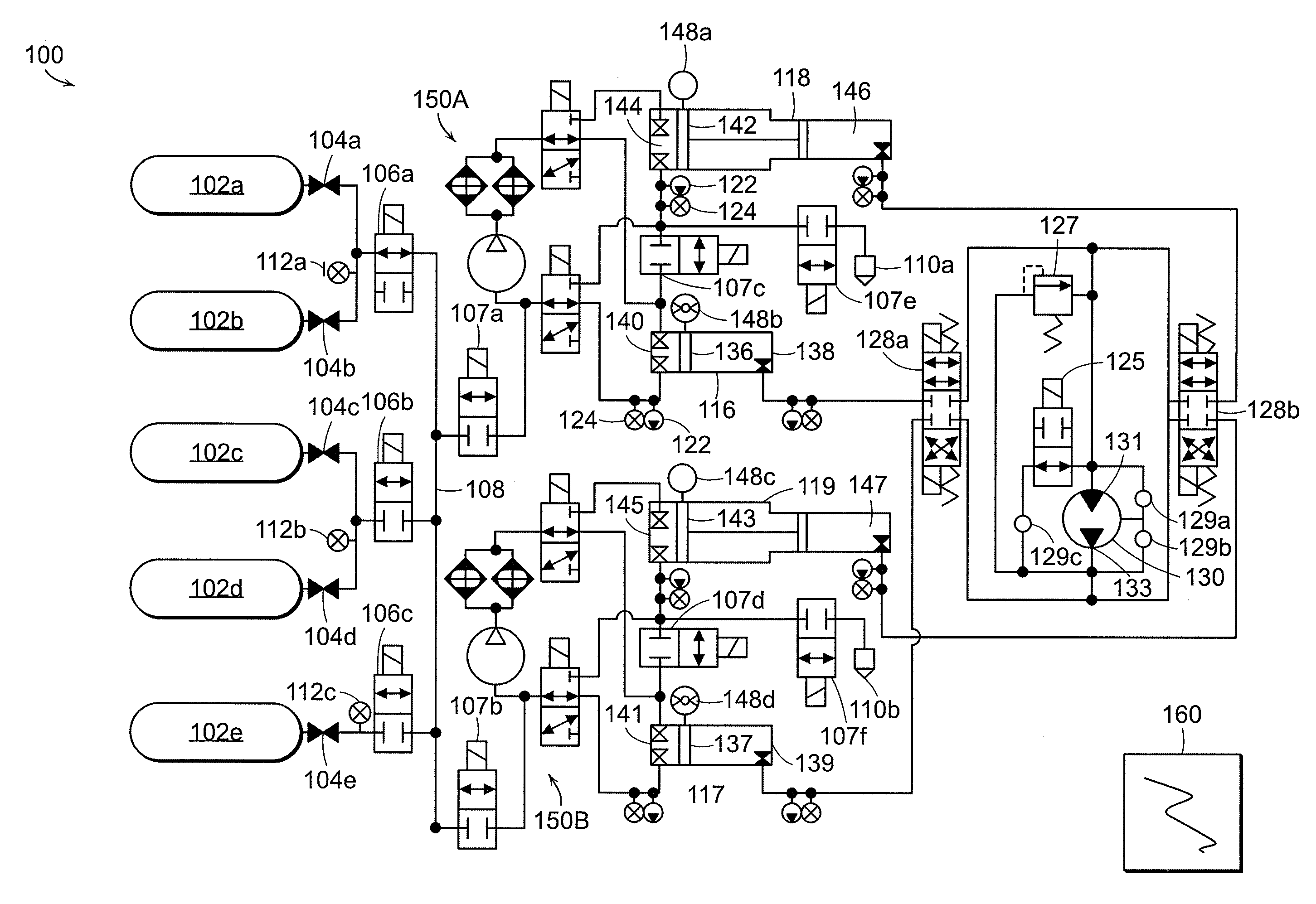

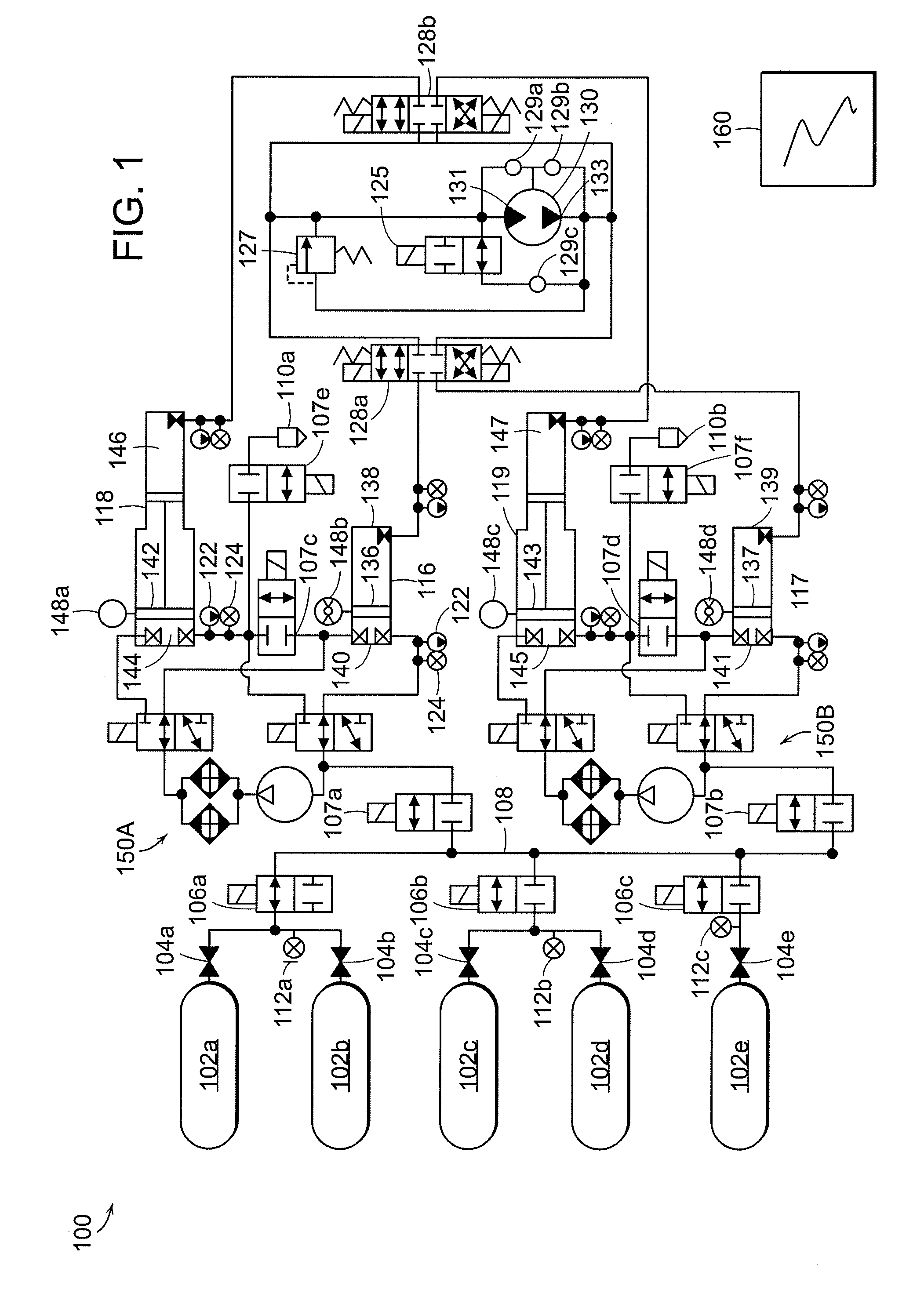

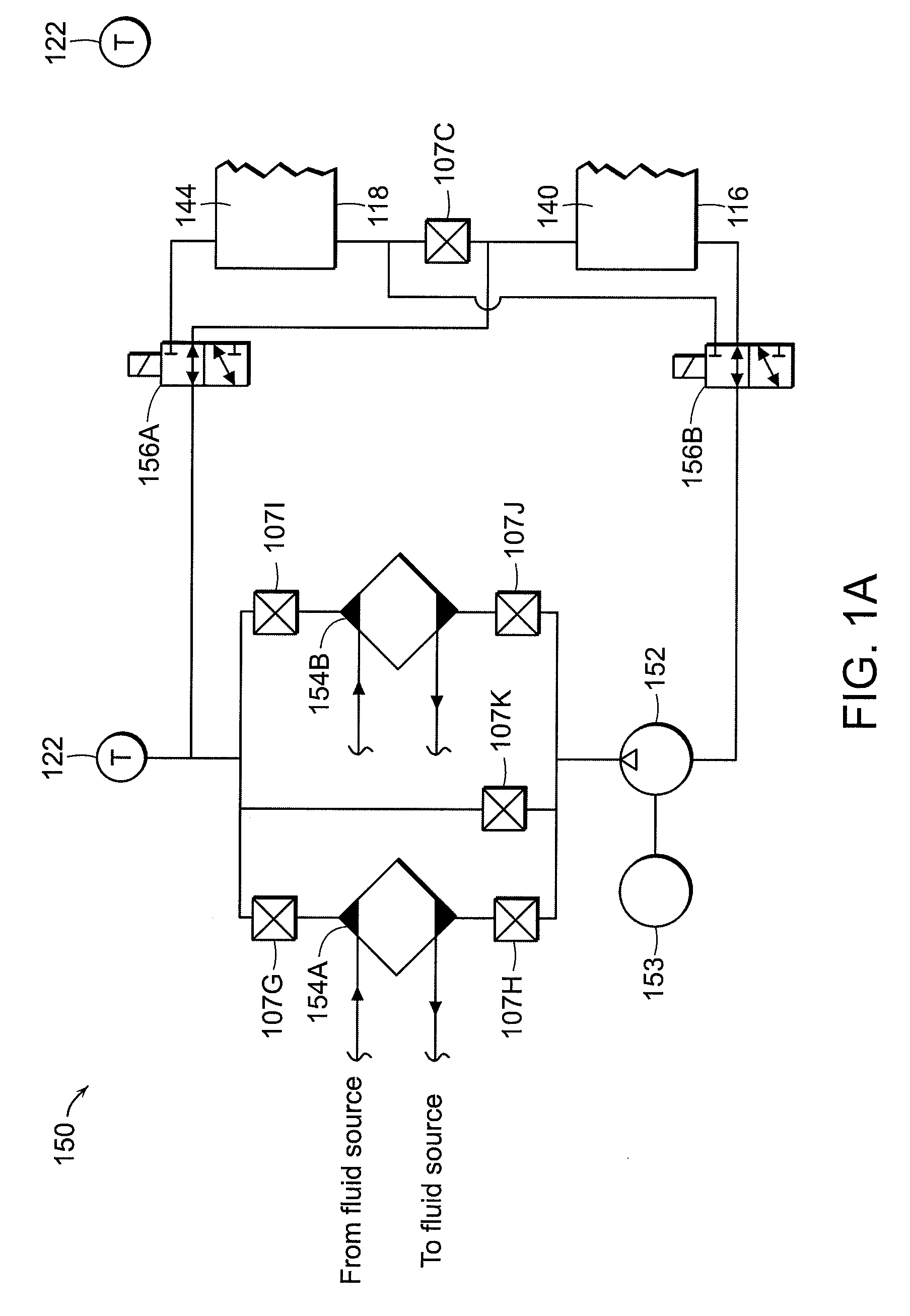

[0036]FIG. 1 depicts generally a staged hydraulic-pneumatic energy conversion system that stores and recovers electrical energy using thermally conditioned compressed fluids and incorporates various embodiments of the invention. Various types of staged hydraulic-pneumatic energy conversion systems that store and rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com