Hydraulic accumulator health monitor

a technology of accumulator and health monitor, which is applied in the direction of fluid couplings, couplings, mechanical equipment, etc., can solve the problems of degree of error that may be associated with the operation health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

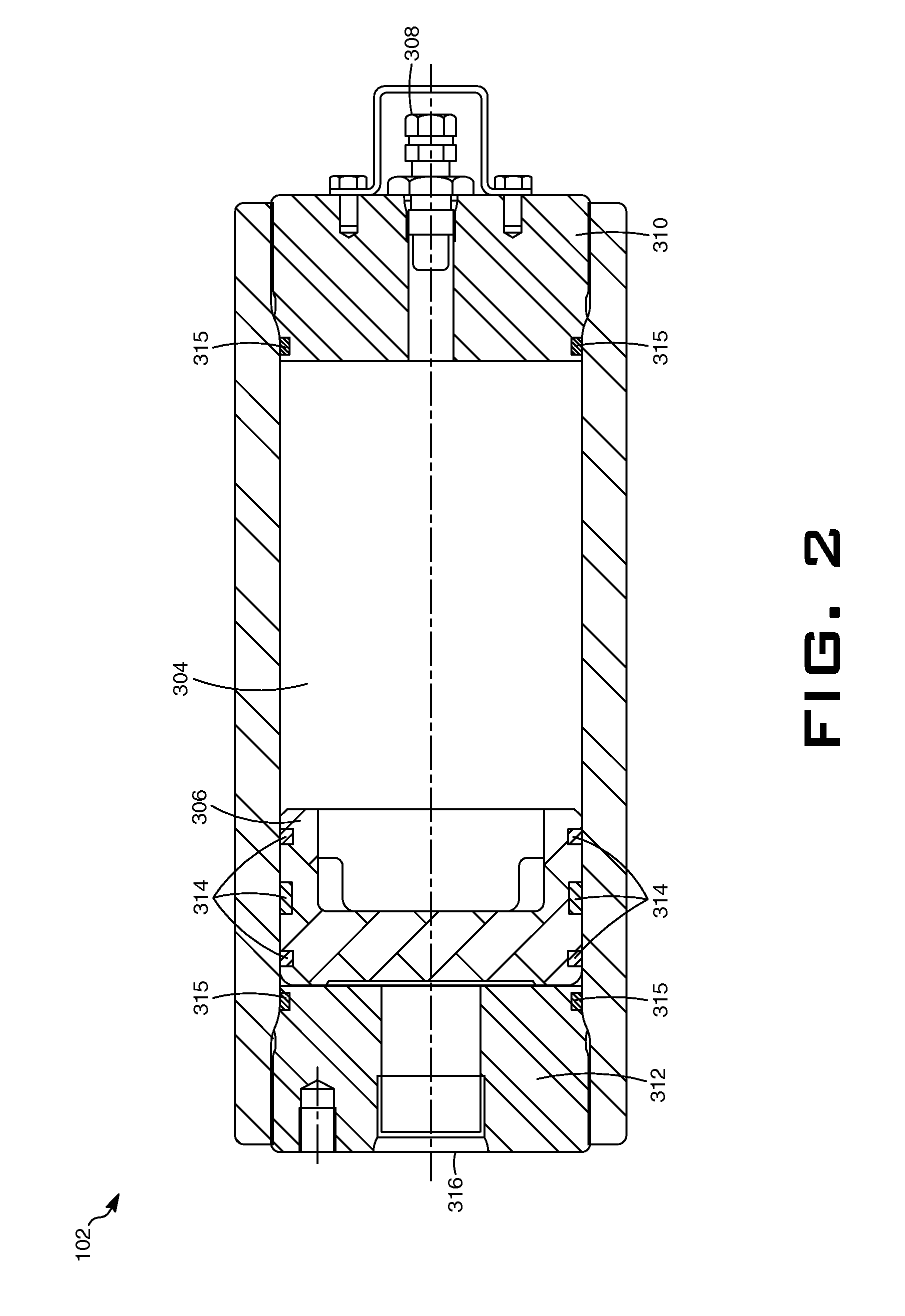

[0016]FIG. 1 illustrates an exemplary system 100 including a hydraulic accumulator 102, a pressure sensor 104, a fluid source 106 and a controller 108, according to one embodiment of the present disclosure. The system 100 may be embodied in any machine such as excavators, wheel loaders, tractors and other machinery. The hydraulic accumulator 102 may be a piston-based accumulator, a bladder-based accumulator, membrane / spring-biased accumulator, or other kind of pressurized fluid storage device that can be selectively charged and discharged. One or more valves (not shown) may be associated with the system 100 to selectively control charging and discharging of the accumulator. For example, one or more valves may be open to permit charging and / or discharging of the accumulator, whereas one or more valves (same or different) may be closed to permit charging and / or discharging.

[0017]Hydraulic accumulator 102 may embody pressure vessels filled with a compressible gas that are configured to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com