Composite rolling active-tooth transmission device and method for performing transmission by using the same

A technology of movable tooth transmission and movable tooth, which is applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of increasing manufacturing cost, difficulty in processing, assembly, and high installation accuracy, and achieves flexible use and improved power. Density, the effect of improving transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the protection scope of the appended claims of the present invention.

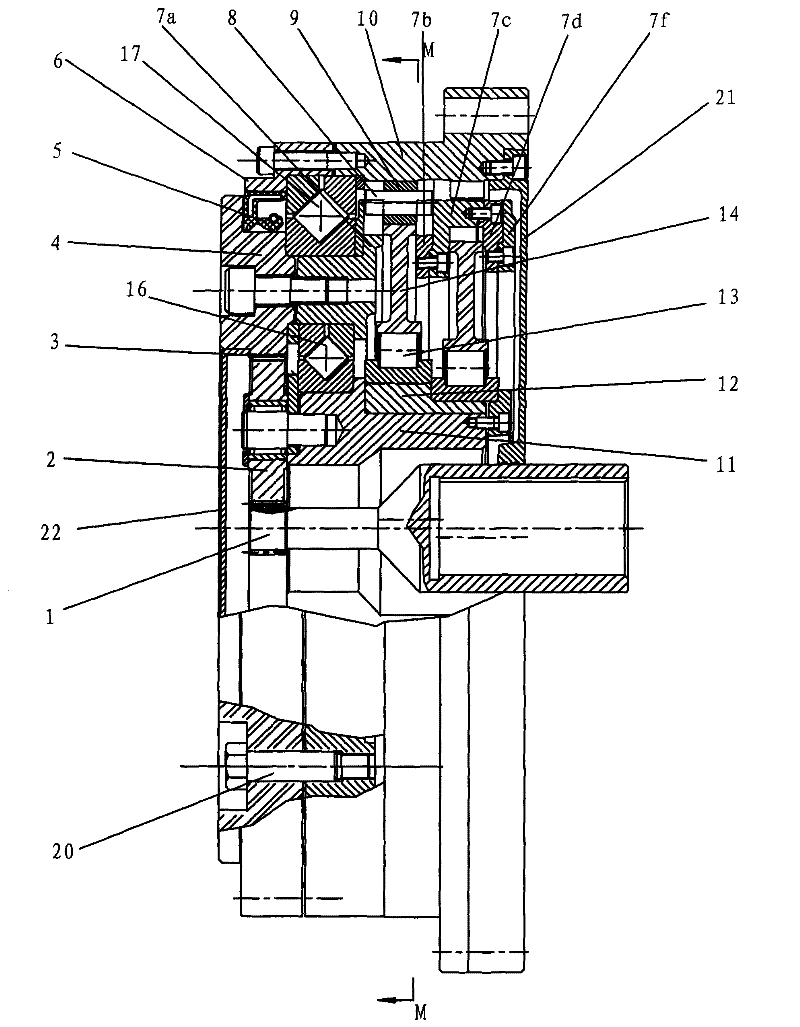

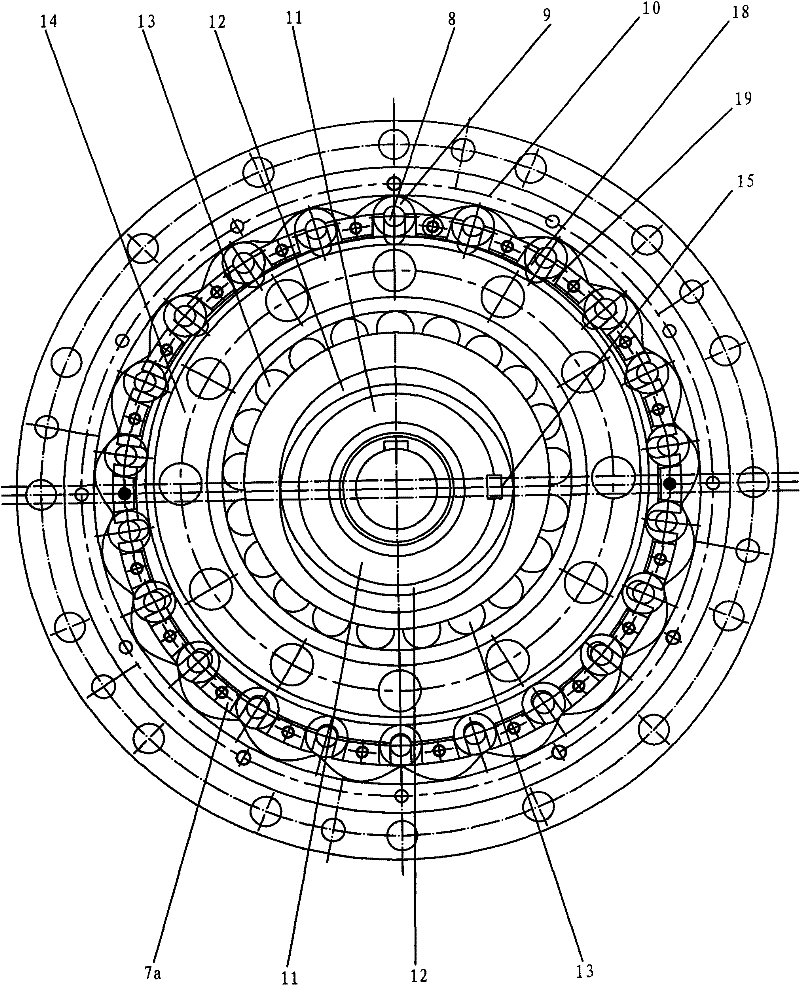

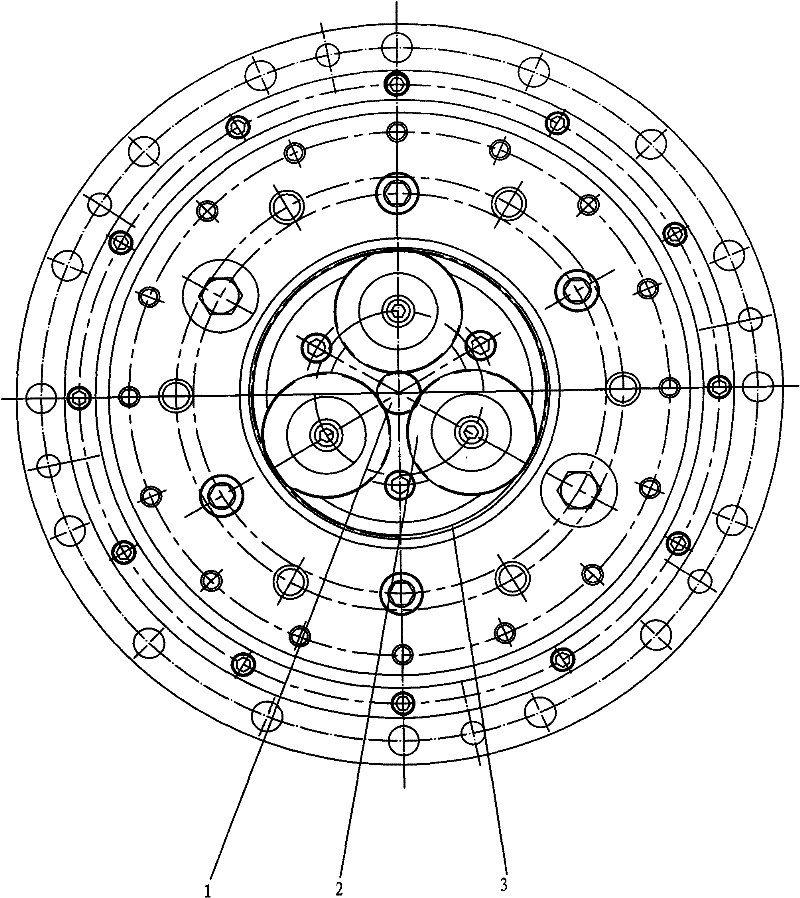

[0053] see figure 1 and refer to figure 2 and image 3, as shown in the figure, the compound rolling movable tooth transmission device of the present invention includes a first transmission gear train, a second transmission gear train and an external force transmission plate, wherein the first transmission gear train is a movable tooth transmission gear train, and the first transmission The gear train is a planetary gear train.

[0054] The movable tooth drive train includes a shock wave, a movable tooth gear and a fixed tooth gear. The shock wave device includes an eccentric wheel 12, a rolling bearing 13 and a shock wave plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com