Two-stage sine hammer-shaped pin roller movable tooth reduction gear

A movable tooth reducer and hammer-shaped technology, which is applied in the field of reduction machinery, can solve the problems of large axial structure and difficulty in realizing large reduction ratio transmission, and achieve the effects of shortening the axial size, increasing rigidity, and increasing bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below in conjunction with embodiment the present invention is described in further detail:

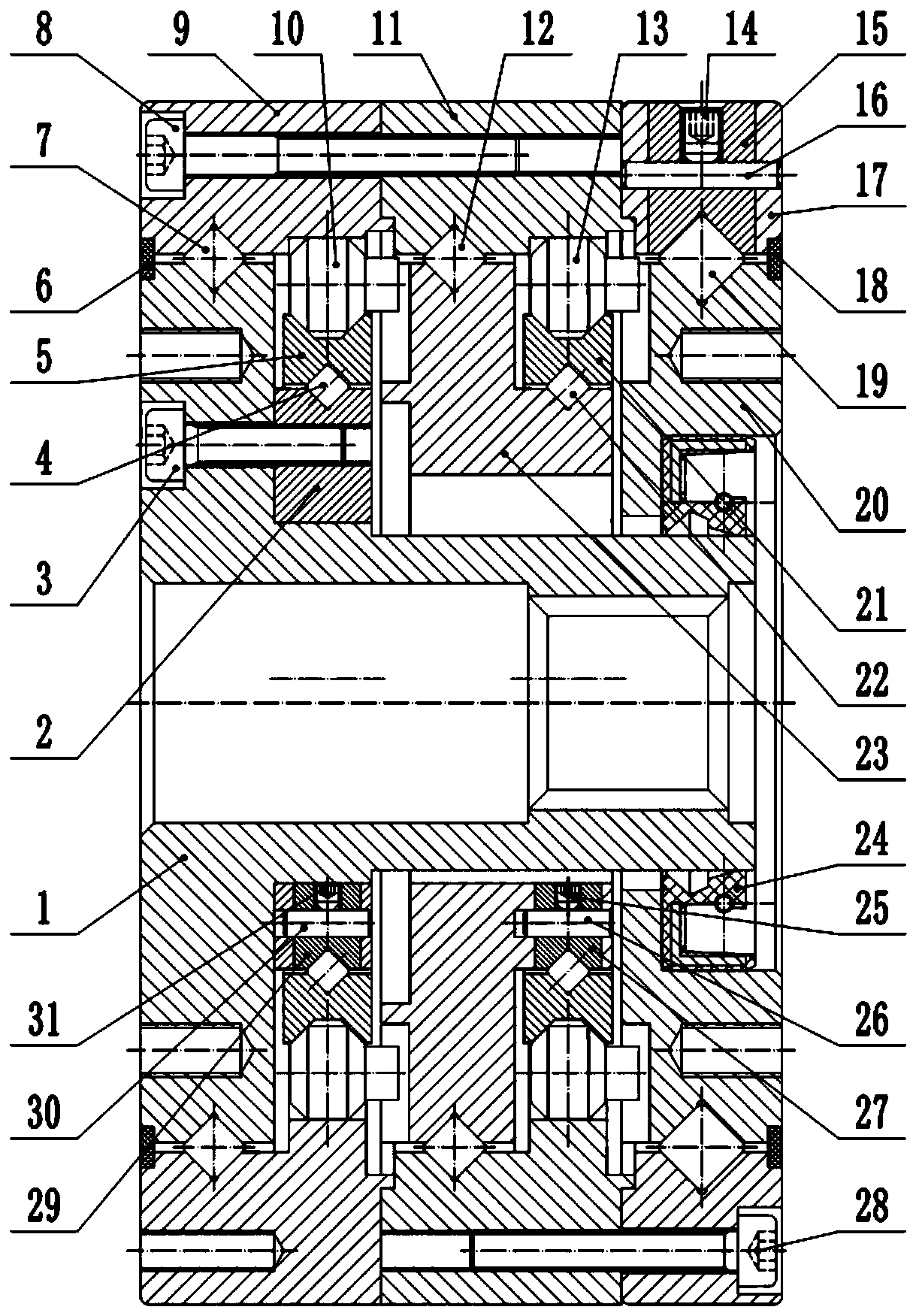

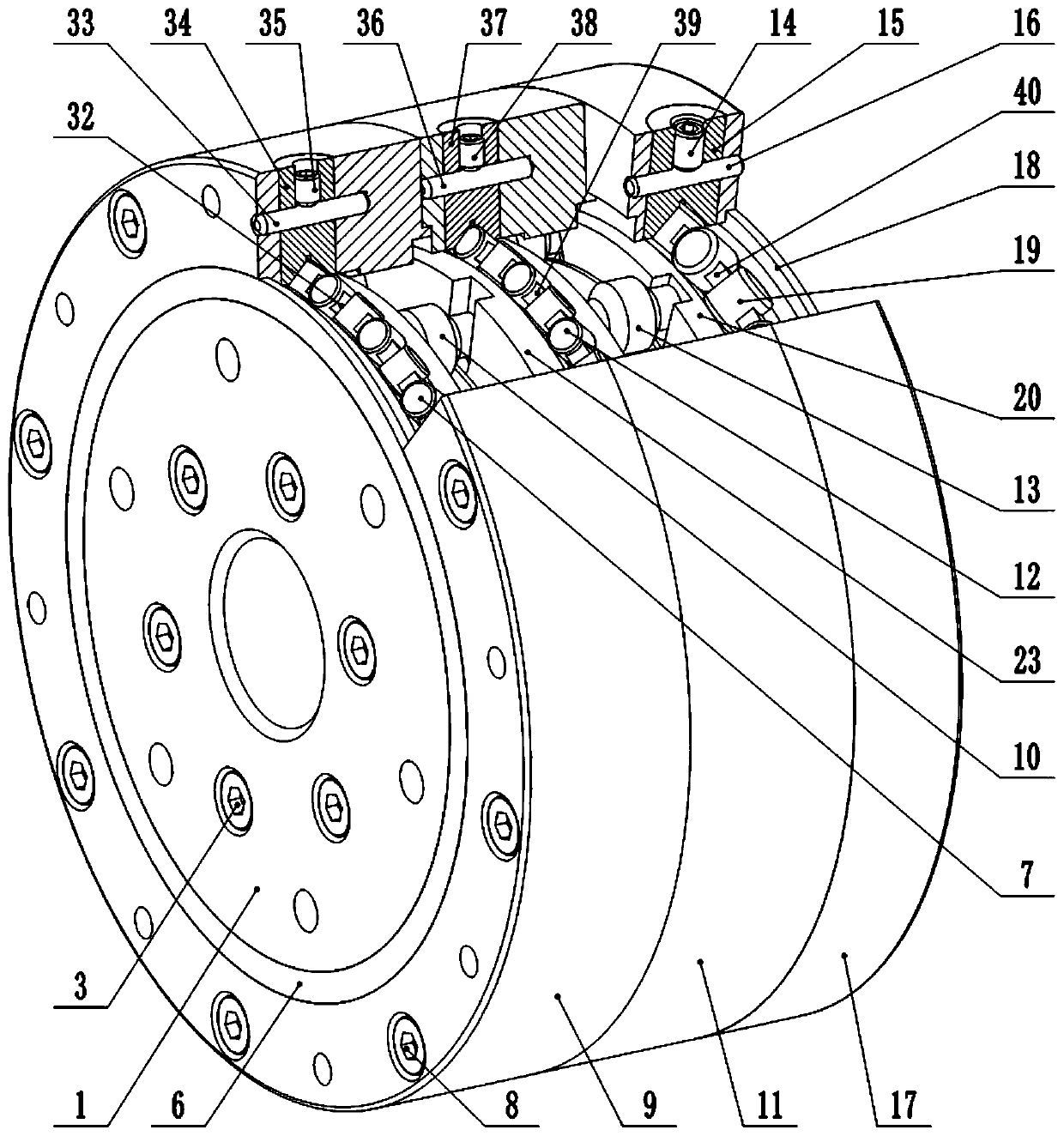

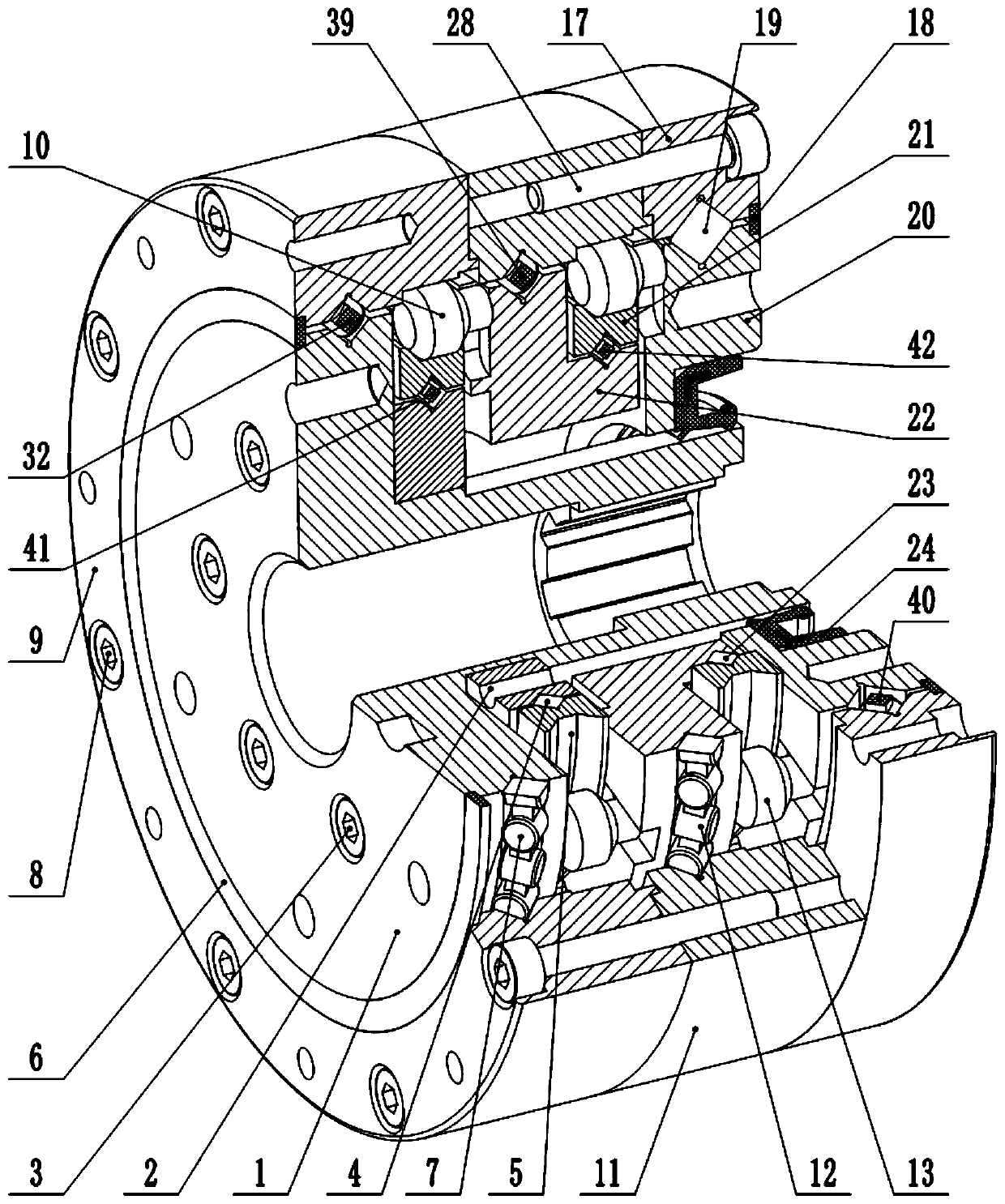

[0050] A double-stage sine hammer roller movable tooth reducer, such as Figure 1-11 As shown, it includes the input shaft 1, the inner ring of the first-stage shock wave 2, the first screw 3, the outer ring of the first-stage shock wave 5, the second screw 8, the first housing 9, and the movable teeth of the first-stage hammer roller 10. Second shell 11, secondary hammer roller movable tooth 13, third shell 17, secondary movable tooth frame 20, secondary shock wave outer ring 21, primary movable tooth frame 23, third screw 28. The first housing 9 is fixedly installed on the side of the second housing 11 through eight evenly distributed second screws 8, and the third housing 17 is fixedly installed on the second side through eight evenly distributed third screws 28. The other side of the second housing 11; the input shaft 1 is hinged in the first housing 9, and there is a circl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com