Face gear-type planetary reduction gearbox

A planetary reduction box, planetary reduction technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of difficult manufacturing and installation, high manufacturing cost, complex structure, etc., to achieve convenient manufacturing and installation, and installation accuracy. Low requirements and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

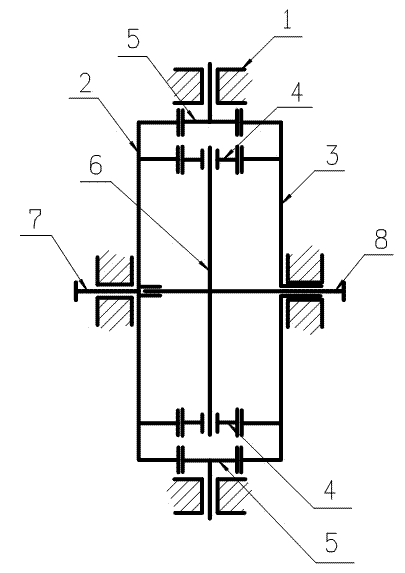

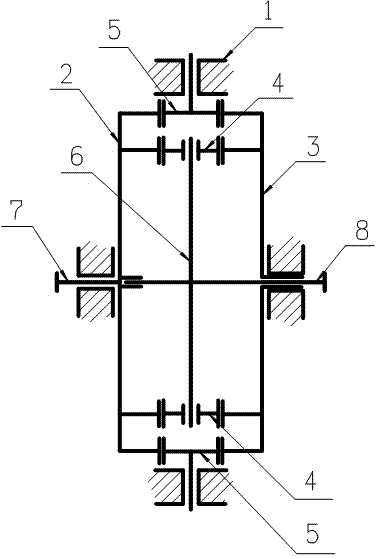

[0016] Such as figure 1 As shown, the face gear planetary reduction box of the present invention includes a casing 1, and a first transmission shaft 7 and a second transmission shaft 8 are respectively coaxially rotated on the opposite sides of the casing 1. On the first transmission shaft 7 and the second transmission shaft 8 are connected with a planetary reduction mechanism, and the planetary reduction mechanism includes a first face gear set 2 and a second face gear set 3 which are respectively rotatably assembled on the box body, the tooth faces are opposite, and the size and structure are the same. , both gear sets 2 and 3 are duplex gears, on which are coaxially provided with an inner ring gear close to the axis and an outer ring gear far away from the axis, between the corresponding inner ring gears on the two gear sets 2 and 3 The meshing transmission has a planet carrier 6, on which more than two planetary gears 4 are rotated and assembled, and each planetary gear 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com