Electric transmission device

An electric drive and brake technology, which is applied in the power plant, motion deposition, transportation and packaging, etc., can solve the problems of increasing the volume of the electric drive device, and achieve the effect of compact structure, simplified box structure and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to understand the technical content of the present invention more clearly, the following examples are given in detail. It should be understood that the examples are only used to illustrate the present invention, not to limit the present invention.

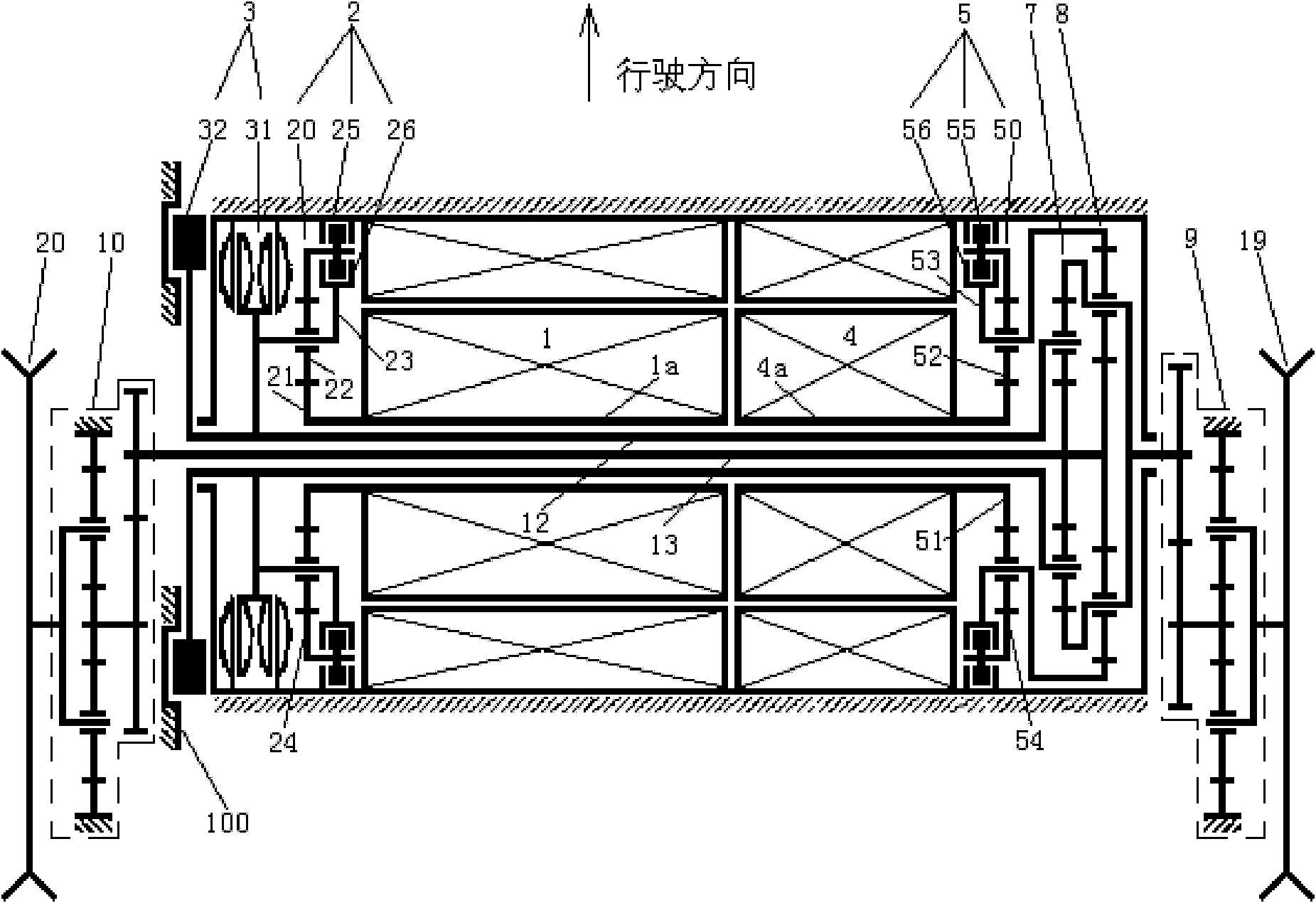

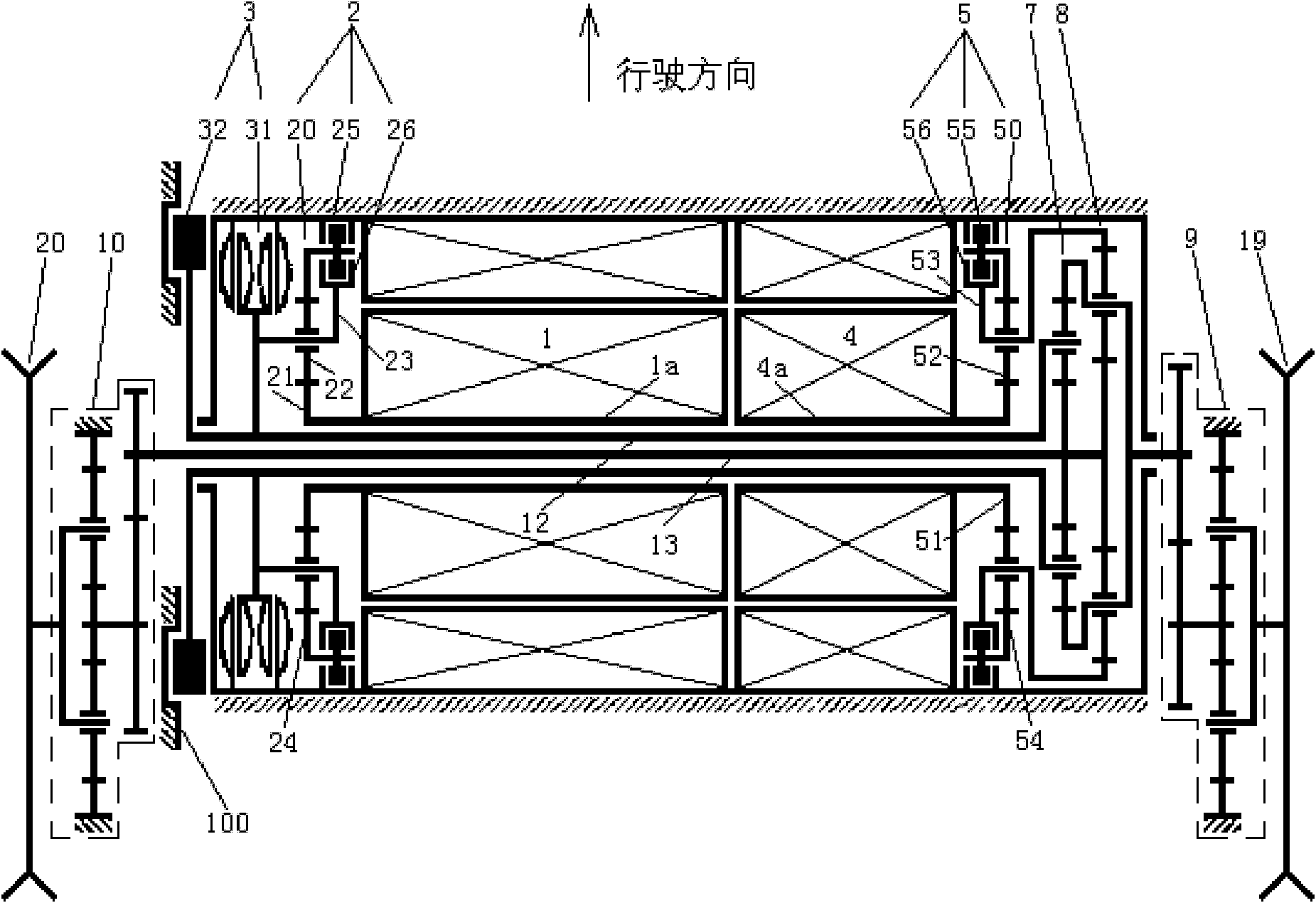

[0025] figure 1 It is a system block diagram of the electric transmission device involved in the embodiment of the present invention. refer to figure 1 , the electric transmission device includes: a drive motor 1, which is used to drive the vehicle, and includes a hollow drive motor rotor shaft 1a. The direct drive speed change mechanism 2 is used for transforming the torque characteristics of the drive motor 1 . The composite braking mechanism 3 is used for longitudinal braking of the vehicle.

[0026] The steering motor 4, which is used to drive the steering of the vehicle, includes a hollow steering motor rotor shaft 4a. The steering speed change mechanism 5 is used for transforming the torque characteristic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com