Internal wave type non-crankshaft internal combustion engine

An internal combustion engine without crankshaft technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of shortened life of internal combustion engines, large axial size, difficult processing, etc., to eliminate friction and wear and friction power consumption, axial Reduced size and volume, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

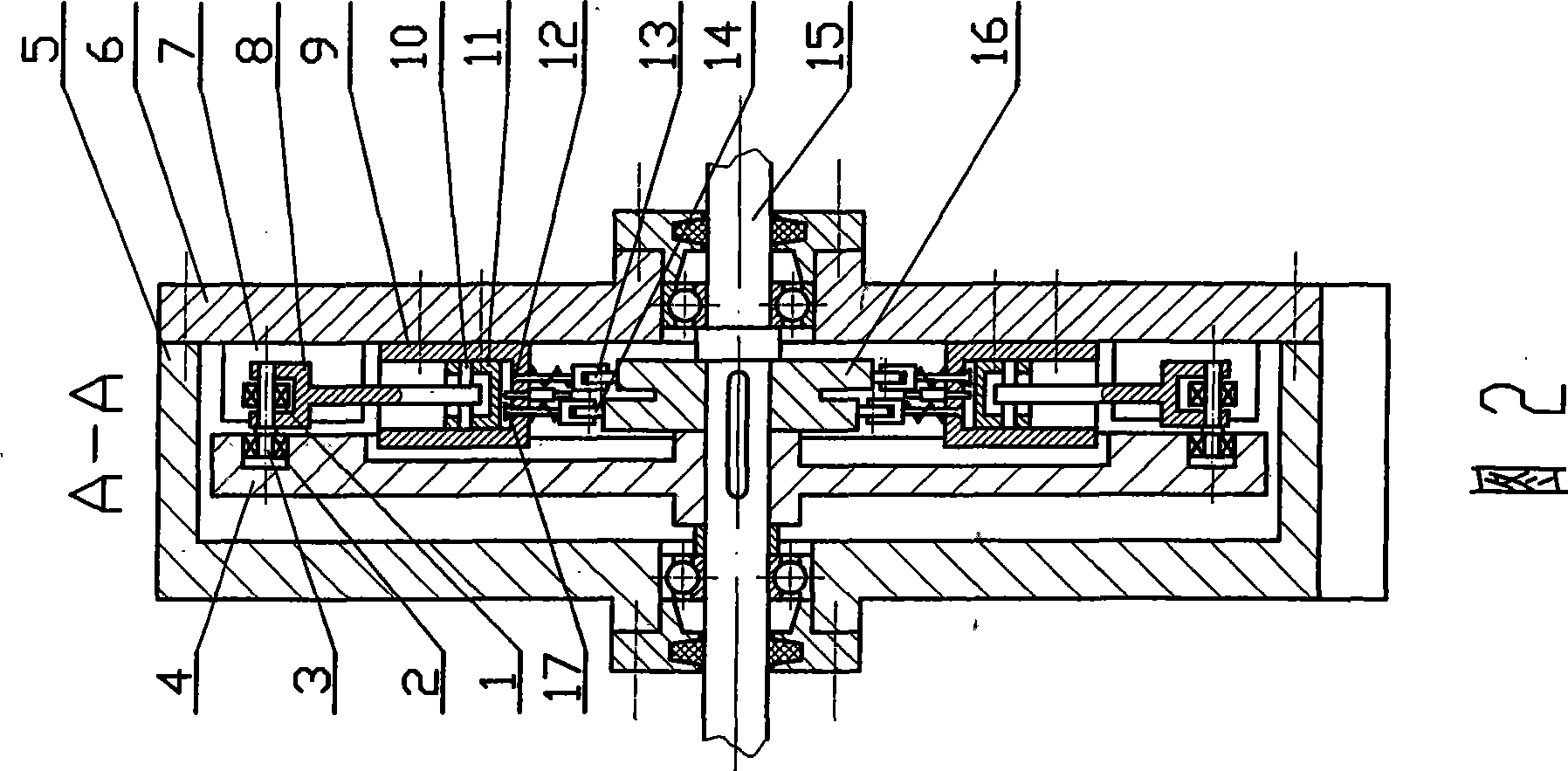

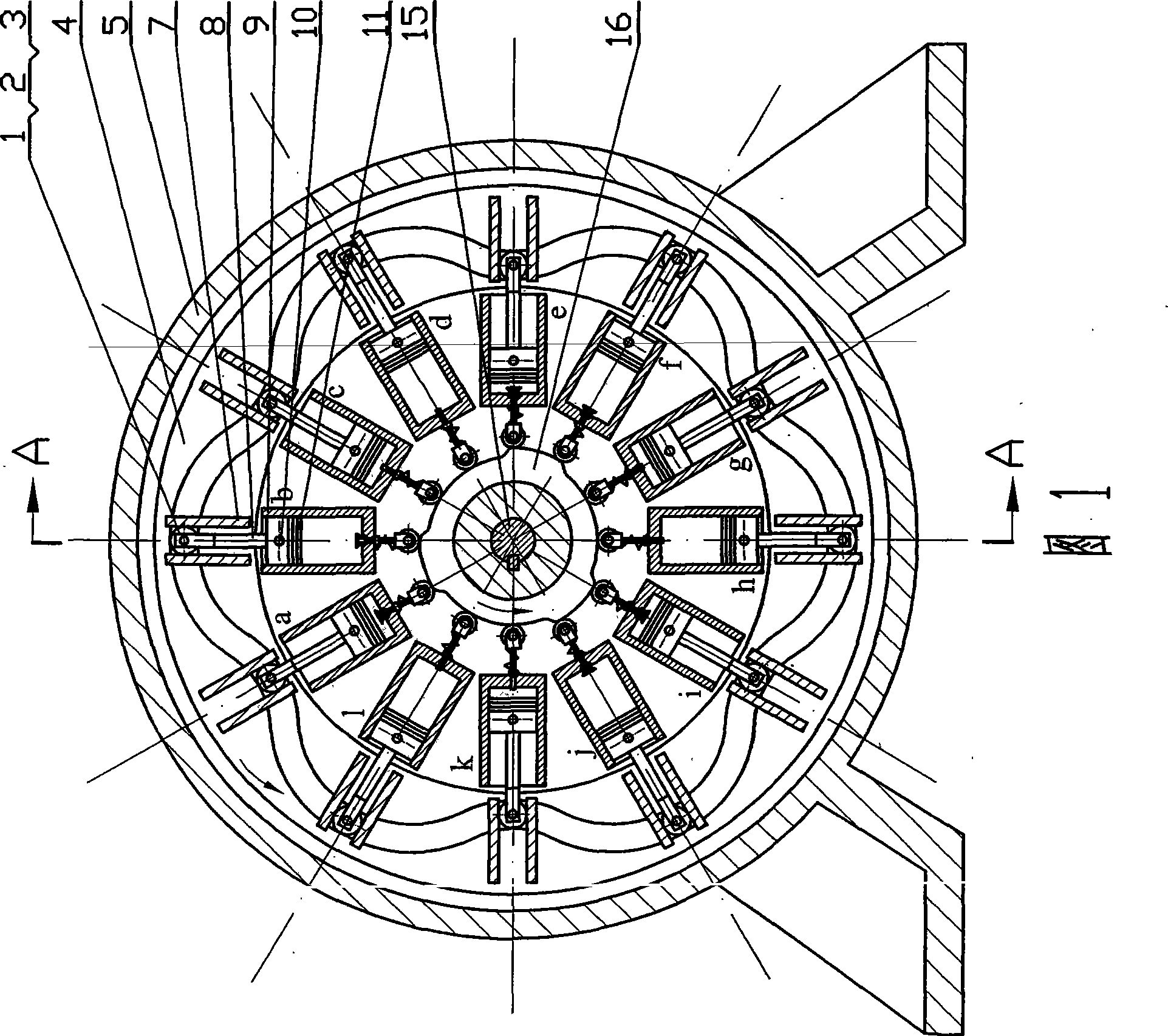

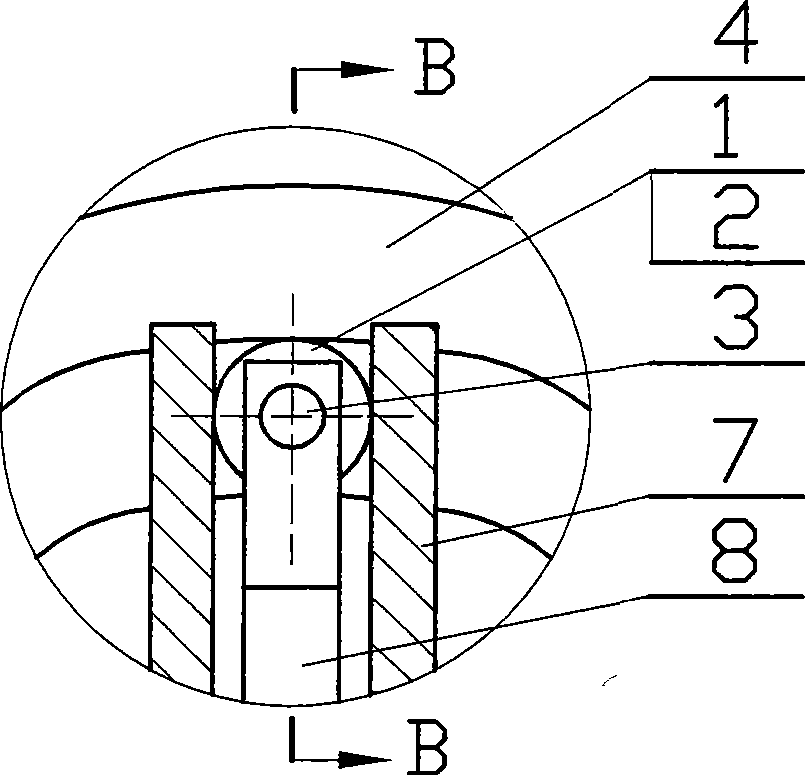

[0027] In Figure 1~ Figure 7 In the twelve-cylinder internal wave type crankshaftless internal combustion engine shown, the internal wave wheel (4) is fixed on the output shaft (15), and the output shaft (15) is supported on the machine base (5) and the body ( In 6), the output shaft (15) is a simple support structure, the machine base (5) and the machine body (6) are connected as a whole with bolts, and the twelve cylinders (9) are symmetrically arranged in the center of the inner wave wheel (4). The rings are evenly distributed on the periphery of the double-connected gas distribution cam (16), and are fixed to the body (6) with bolts. The angle between two adjacent cylinders is 30°, and the piston (11) and cylinder (9) are cylindrical or Cylindrical, similar to the structure of the piston and cylinder in the existing reciprocating internal combustion engine, the double-connected gas distribution cam (16) is fixedly connected with the output shaft (15) and rotates together ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com