hydraulic cylinder piston

A technology of cylinder piston and hydraulic cylinder, applied in the direction of fluid pressure actuating device, etc., can solve the problems of increasing the difficulty of hydraulic cylinder or cylinder control circuit design, inability to eliminate shock vibration and noise, and affecting the buffer effect, etc. Reliable work and good buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

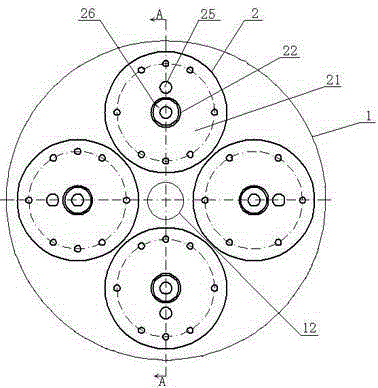

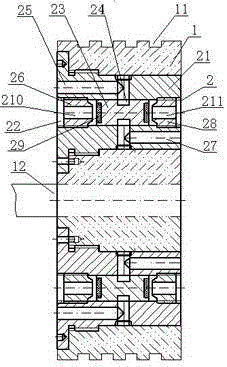

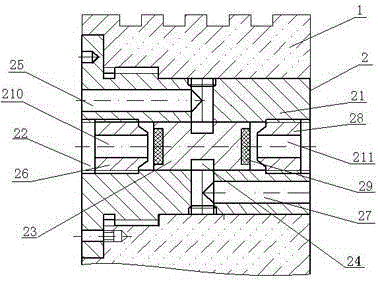

[0022] See figure 1 , figure 2 with image 3 : The present invention includes a piston body 1 and a buffer mechanism 2 arranged on the piston body 1 to relieve pressure.

[0023] Among them, the piston body 1 is a cylindrical structure with a certain thickness, and its thickness and diameter are reasonably determined according to the performance of the applied hydraulic cylinder. On the circumference of the piston body 1, there are four annular sealing grooves 11 filled with sealing rings. The number of the sealing grooves 11 is also reasonably determined according to the performance of the hydraulic cylinder, such as two, three, etc., which are mainly used to prevent During the working process of the hydraulic cylinder, the hydraulic oil leaks freely from the high pressure chamber (that is, the pressure side of the piston) to the low pressure chamber (that is, the pressure discharge side of the piston). A piston rod 12 is connected to the aforementioned piston body 1, and the p...

Embodiment 2

[0031] The other structure of this embodiment is the same as that of the first embodiment, the difference is that: the buffer housing and the piston body constituting the buffer mechanism are an integrated structure, that is, the piston body itself also serves as the buffer housing, in a predetermined position of the piston body (that is, The position for assembling the buffer mechanism in embodiment 1) is provided with an axial through-hole-shaped pressure relief hole, two end hole wall sections of the pressure relief hole are provided with connecting threads, and the piston near the pressure relief hole The left end surface of the body is provided with a first diversion hole leading to the middle of the pressure relief hole, and the right end surface is provided with a second diversion hole leading to the middle of the pressure relief hole. The pressure relief hole and the diversion hole (that is, the first diversion hole and the second diversion hole) provided on the piston b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com