Full variable valve engine and control method thereof

An engine and valve mechanism technology, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as easy misfire, low combustion temperature, and difficulty in ignition, and achieve long service life, low noise, and low impact vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

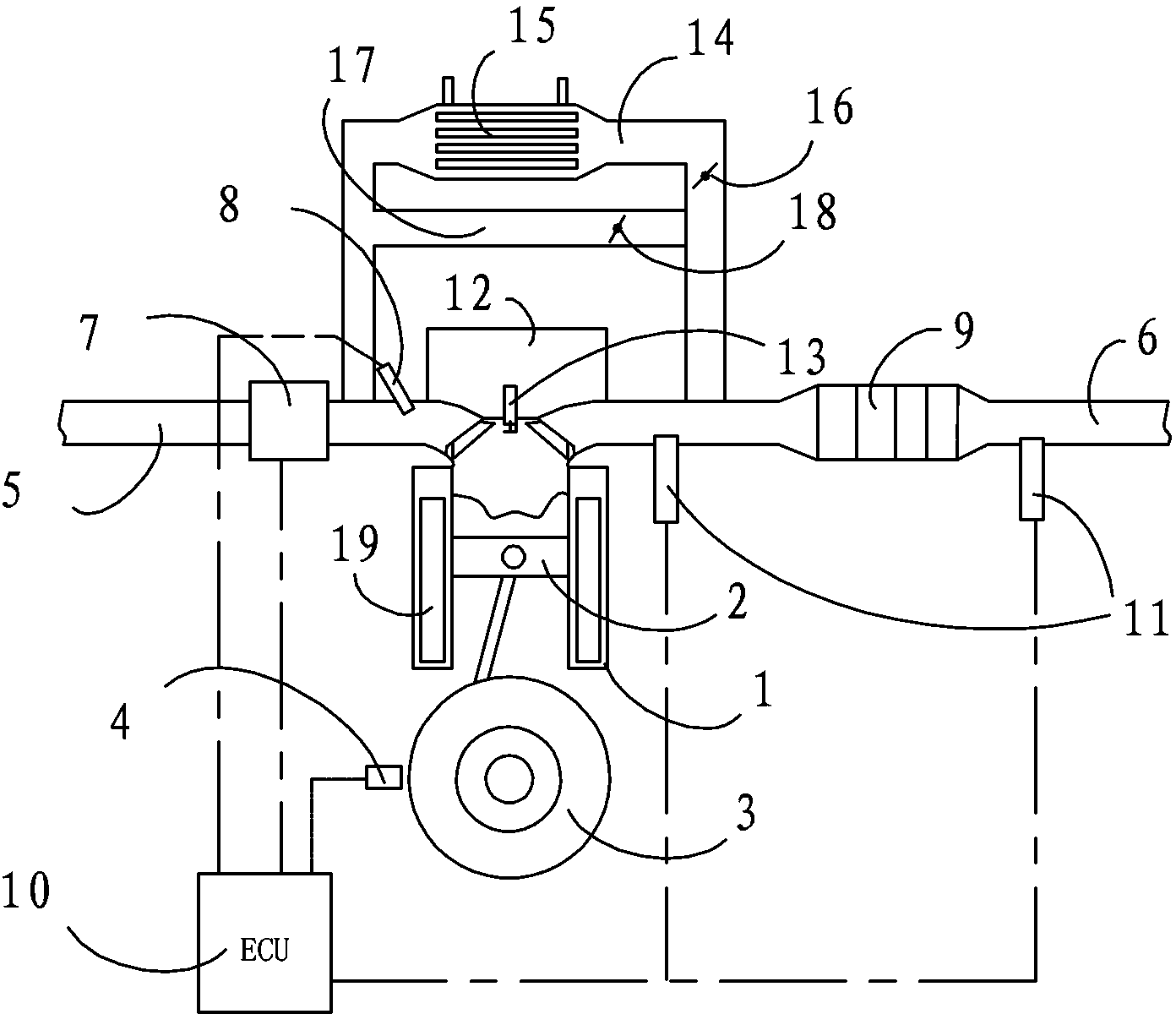

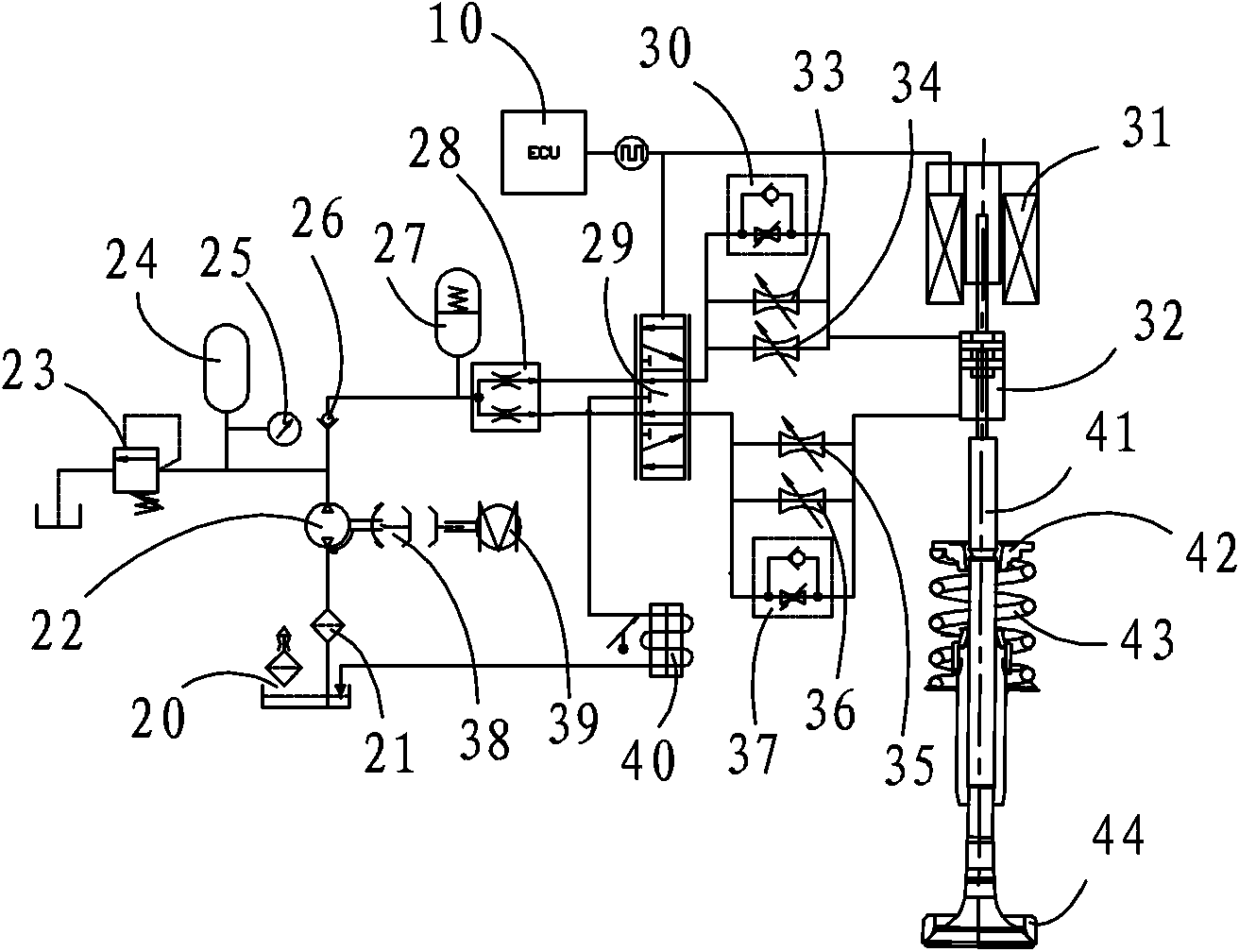

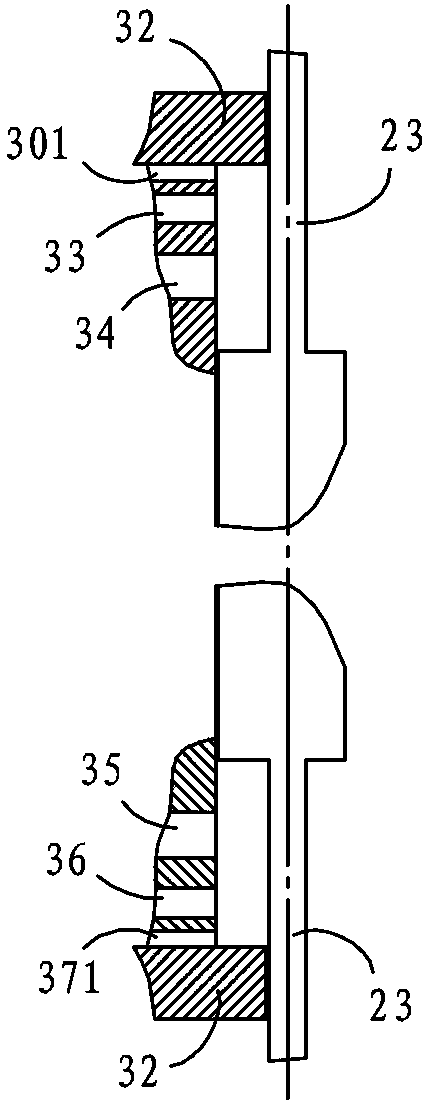

[0033] This embodiment relates to a fully variable valve engine, which uses a mixture of gasoline and ethanol as fuel, such as figure 1 As shown in , it includes a cylinder 1, a piston 2 is arranged in the cylinder 1, and a crank connecting rod mechanism 3 is connected to the lower end of the piston 2. The upper part of the cylinder 1 is communicated with an intake passage 5 and an exhaust passage 6 , a throttle valve 7 is arranged on the intake passage 5 , and a fuel injector 8 is also arranged downstream of the throttle valve 7 in the intake passage 5 . An exhaust gas treatment unit 9 is arranged on the exhaust passage 6 , and the exhaust gas treatment unit 9 can be a conventional three-way catalytic converter for treating the exhaust gas discharged from the cylinder 1 . Oxygen sensors 11 are respectively arranged on both sides of the exhaust gas treatment unit 9 in the exhaust passage 6 for detecting exhaust gas so as to regulate engine operation. A spark plug 13 is arrang...

Embodiment 2

[0043] This embodiment relates to a control method of a fully variable valve engine, and the fully variable valve engine has the structure of the fully variable valve engine in the first embodiment above. The control method of this fully variable valve engine comprises the steps described below, and its overall process can be as follows Figure 4 shown in .

[0044] When the engine is started, especially when the engine is started at a low temperature, because the temperature in the engine cylinder 1 is low, it is not conducive to the compression ignition in the CAI mode, so at this time the SI combustion mode ignited via the spark plug 13 can be used, that is, the mode One, in order to realize the smooth ignition and warm-up of the engine. At this time, the ignition timing of spark plug 13 is controlled by ECU10, and the intake valve and exhaust valve in the fully variable valve train on intake port 5 and exhaust port 6 can be fixed timing opening and closing under the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com