Crane boom mechanism and crane

A crane and jib technology, applied in the field of hoisting equipment, can solve the problems affecting the telescopic performance of the main boom, difficult operation of the mechanical structure, and high cost of the hydraulic cylinder structure, and achieve the effects of ingenious design, small shock jitter, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0039] In the present invention, the terms "first" and "second" are mainly used to distinguish different components, but do not specifically limit the components. In the case of no conflict, the technical features in the various embodiments can also be combined with each other.

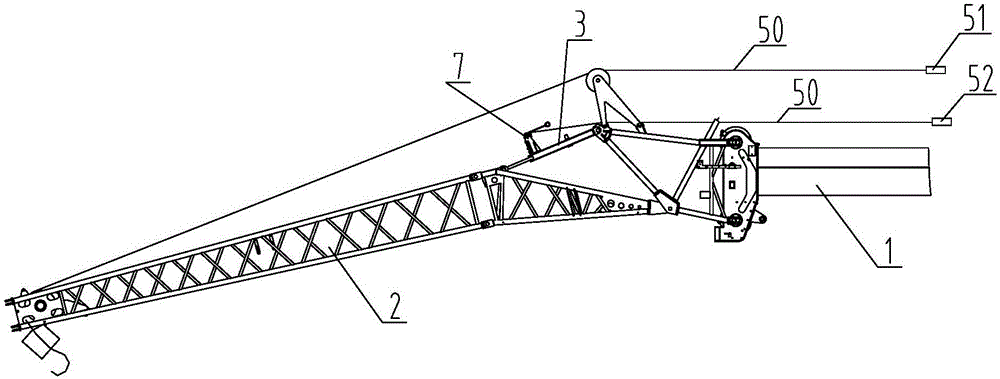

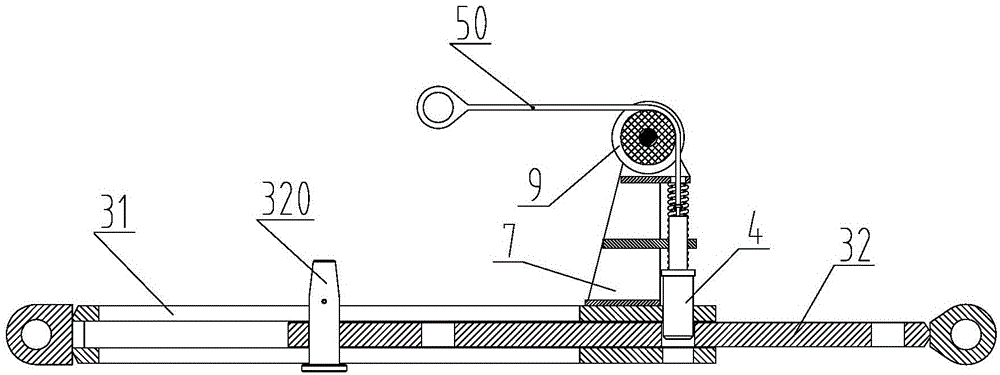

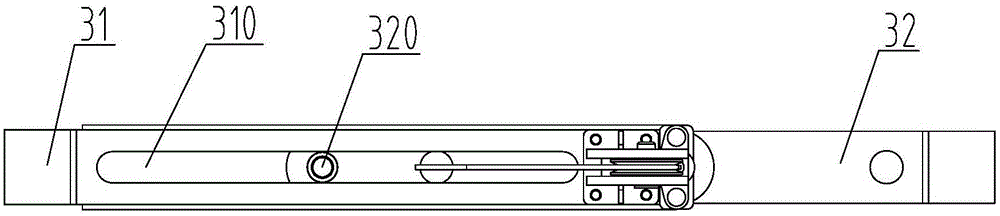

[0040] figure 1 Shown is a schematic structural view of a crane jib mechanism according to an embodiment of the present invention. The jib mechanism of this embodiment includes a main arm 1 and an auxiliary arm 2 . The auxiliary arm 2 is swingably arranged at the end of the main arm 1 . After the relative angle between the auxiliary jib 2 and the main jib 1 is changed, the working range and hoisting height of the crane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com