Dynamic performance testing machine of joint bearing and transmission shaft rotation drive unit thereof

A dynamic performance and joint bearing technology, applied in the direction of mechanical bearing testing, etc., can solve the problem of large shock and vibration of the driving mechanism, achieve the effects of small shock and vibration, reduce the overall size, and reduce power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

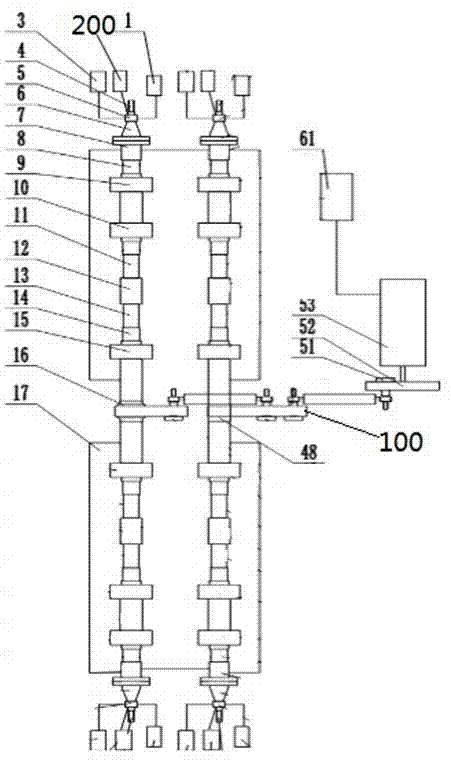

[0023] like Figure 1 to Figure 3 As shown, an embodiment of a dynamic performance testing machine for a joint bearing, the testing machine in this embodiment is a rod end joint bearing testing machine for testing a rod end joint bearing, and the testing machine includes two parallel arrangement The transmission shaft 14 used to drive the inner ring of the rod end joint bearing to be tested to rotate, the two transmission shafts 14 are axial transmission shafts coaxially arranged with the inner ring of the corresponding rod end joint bearing to be tested respectively, and the two transmission shafts 14 A rod end joint bearing is respectively provided at both ends, and when the two transmission shafts are driven to rotate synchronously by the transmission shaft rotation driving device 100, the inner ring of the rod end joint bearing to be tested can be driven to rotate.

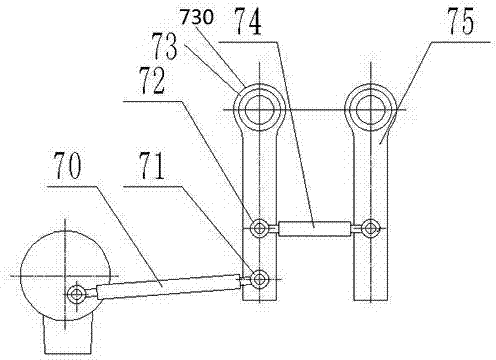

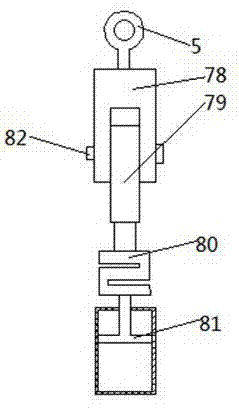

[0024] The transmission shaft rotation driving device 100 in this embodiment includes a parallel linkage me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com