Magnetic vibration damping and positioning incomplete gear

A fully geared, magnetic positioning technology, applied to belts/chains/gears, elements with teeth, portable lifting devices, etc., to reduce impact strength, reduce instantaneous impact vibration, and speed up the positioning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

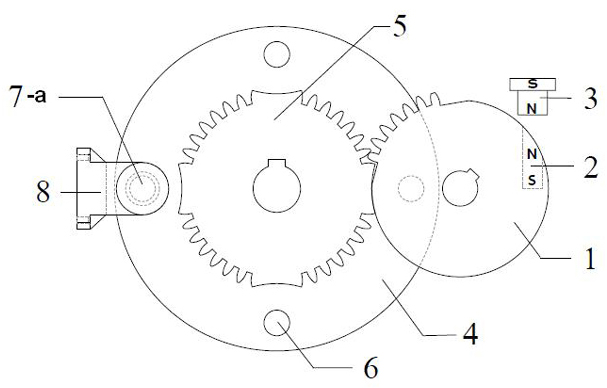

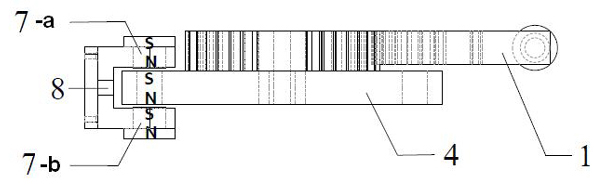

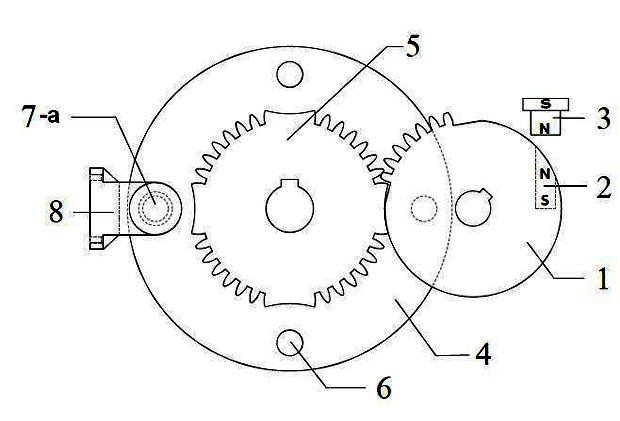

[0014] The following will refer to figure 1 A specific embodiment of the present invention will be described.

[0015] like figure 1 As shown, it is similar to the traditional incomplete gear transmission mechanism. The driven wheel 5 and the positioning index plate 4 are fixedly connected with the rotating shaft through the keyway, so that the index plate and the driven wheel keep rotating synchronously. The index plate 4 is provided with 4 holes, and 4 identical magnetic positioning pins 6 are symmetrically embedded and installed in the 4 holes of the positioning index plate 1 at intervals of 90° along the circumferential direction, and the axes of the magnetic positioning pins 6 and the index plate The axes of 4 are parallel, and 2 positioning magnets are installed on the positioning frame 8. When the centerlines of the magnetic positioning pins 6 and two positioning magnets coincided, the positioning magnets and the magnetic positioning pins 6 were not in contact with e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com