A spinning machine or a twister with a spindle rail capable of performing lifting motion

A technology of lifting movement, twisting machine, applied in the field of spinning machine or twisting machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the following description of the preferred embodiments of the present invention, the same or similar reference numerals are used for the parts shown in the various figures and having similar functions, and the repeated description of these parts is omitted here.

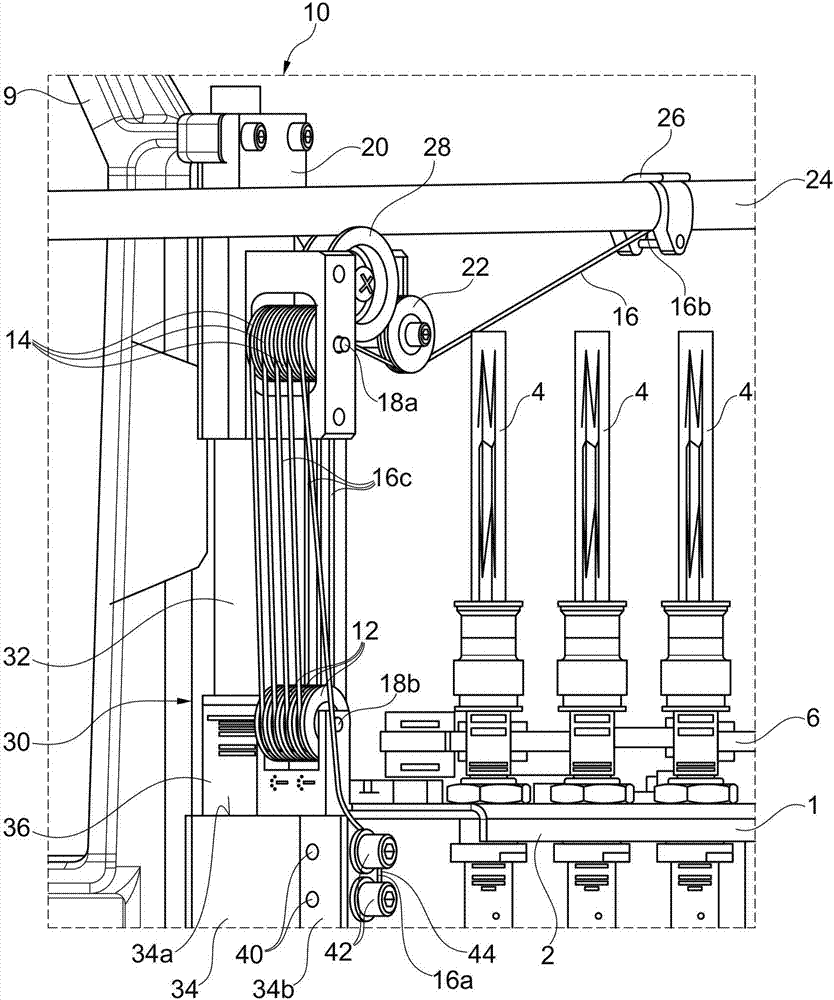

[0028] figure 1 A side perspective view of the pulley block mechanism 10 is shown, which is connected to the longitudinal left end 2 of the spindle rail 1 of a spinning or twisting machine according to one embodiment. The sheave block mechanism 10 is based on the sheave-pull principle and in this embodiment is constructed in the form of a multiplier block. The pulley block mechanism 10 includes four movable pulleys 12 and five fixed pulleys 14, each of which has a groove for guiding a wire rope 16 as a tie. The movable pulley 12 and the fixed pulley 14 are arranged along the same rotation axis 18a, 18b, respectively. The rotary shafts 18a, 18b are parallel to each other and located in the same plane. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com