Online system for disassembling scraped car

A technology for scrapped cars and rolling beds, which is applied in the field of scrapped car dismantling and online systems, can solve the problems of low transportation and dismantling efficiency, huge projects, and complicated equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

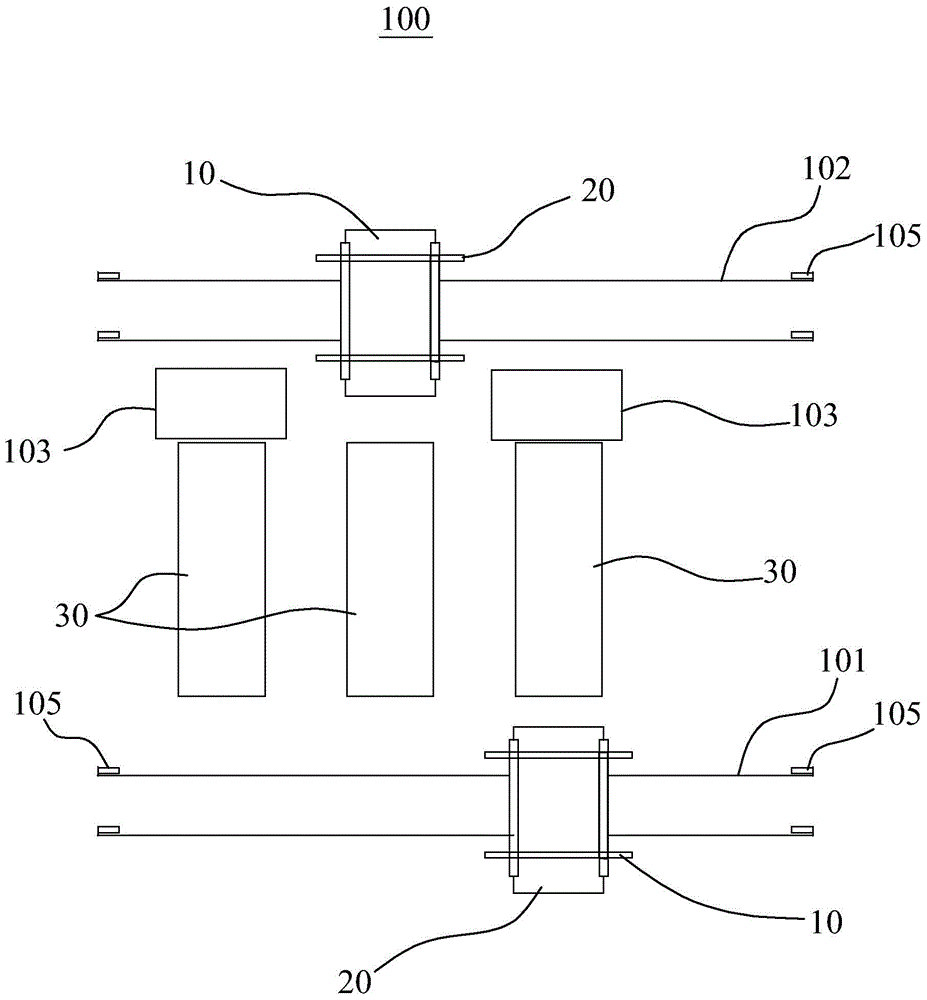

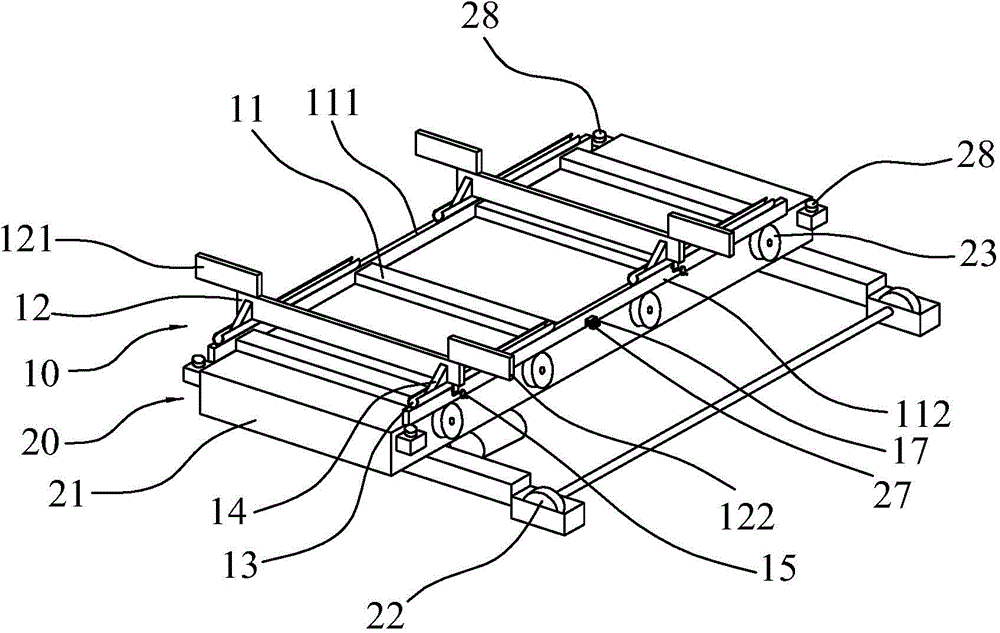

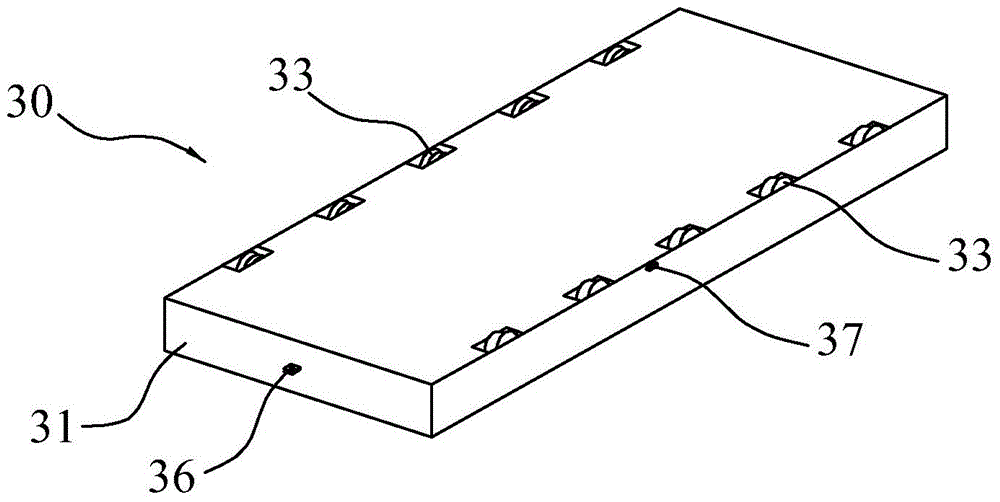

[0015] see Figure 1-4 , shows an online system 100 for dismantling scrapped cars according to an embodiment of the present invention, which is used to send scrapped cars to a dismantling station 103. The online system 100 includes a loading device for scrapped cars and a conveying device for scrapped cars. The loading device for scrapped cars includes a The skid 10 of the automobile, the scrapped automobile conveying device comprises at least two rails 101, 102, a moving machine 20 sliding on the corresponding rails 101, 102 and at least one roller bed 30 positioned at the side of the dismantling station 103, The at least two tracks 101, 102 are divided into two rows and located on both sides of the rolling bed 30, each track 101, 102 is provided with at least one traveling machine 20, and each skid 10 is placed on a corresponding traveling mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com