Device for dismantling electronic equipment and control method thereof

A technology of electronic equipment and control unit, applied in metal processing equipment, manufacturing tools, metal processing and other directions, can solve the problems of labor and time consumption, potential safety hazards, and the need for full manual operation, so as to shorten the operation time and improve the operation safety. The effect of improving the efficiency of dismantling and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described below based on examples, but the present invention is not limited to these examples. In the following detailed description of the invention, some specific details are set forth in detail. The present invention can be fully understood by those skilled in the art without the description of these detailed parts. To avoid obscuring the essence of the present invention, well-known methods, procedures, procedures, and components have not been described in detail.

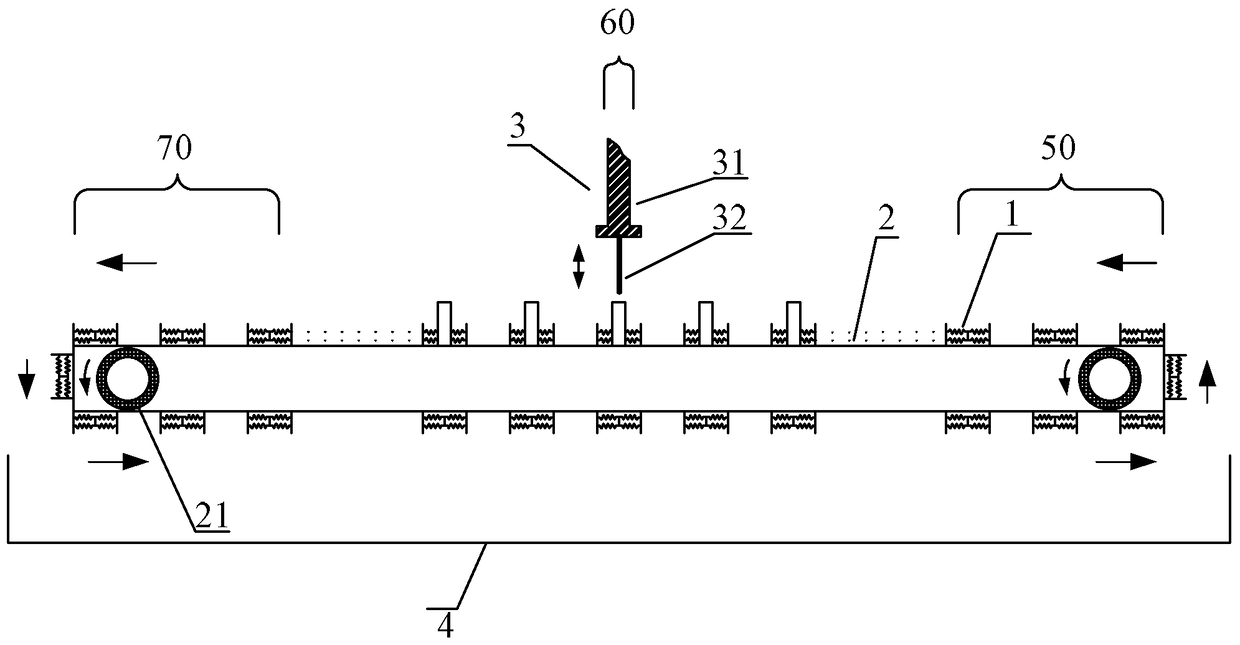

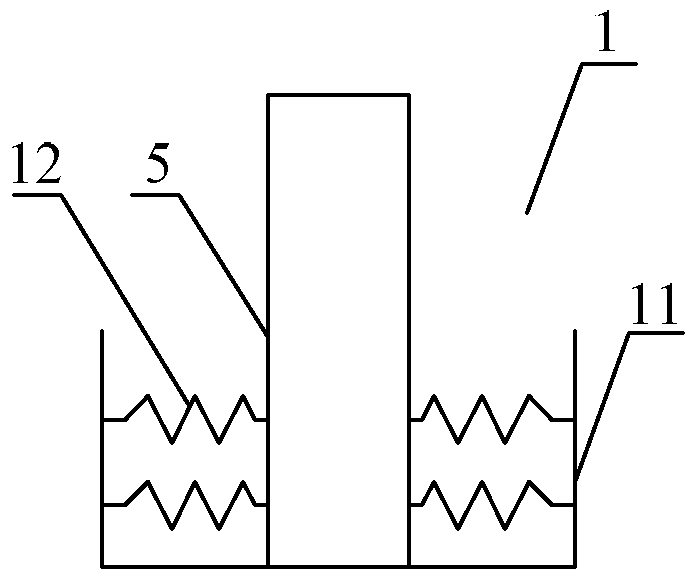

[0024] Such as figure 1 As shown, the present invention relates to a device for dismantling electronic equipment, which includes a transmission mechanism 2, a fixing mechanism 1, a control unit (not shown) and a disassembling mechanism 3; On the transmission mechanism 2 and driven by the transmission mechanism 2, the fixing mechanism 1 is used to fix the electronic device 5; when the fixing mechanism 1 moves to the position of the disassembly mechanism 3, the control unit contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com