Scrapped car dismantling-body packing line

A scrapped car and assembly line technology, applied in the direction of vehicle scrapped recycling, motor vehicles, transportation and packaging, can solve problems such as large volume and waste, and achieve the effect of reducing storage space, high production efficiency, and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

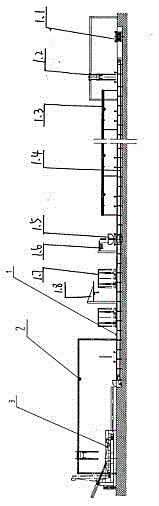

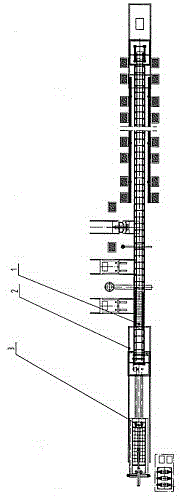

[0025] See attached Figure 1-2 , The present invention relates to a scrapped car dismantling-body packing line, which is mainly composed of a dismantling line 1, a lifting conveyor discharge machine 2, and a packing machine 3. The dismantling line 1 is equipped with a lift, a lifting conveyor, a chain conveyor, a mobile car turning machine, a mobile car lift, a crane suspension slewing bracket, a lighting and power configuration bracket, etc.; 3 is set at the rear end of the dismantling line 1; the lifting conveying and unloading machine 2 is set across the joint area between the dismantling line 1 and the packing machine 3.

[0026] The dismantling line 1 is mainly composed of a lift 1.1, a lifting conveyor 1.2, a lighting and power configuration bracket 1.3, a conveyor 1.4, a mobile car turning machine 1.5, a suspension slewing bracket 1.6, a mobile car lift 1.7 and a crane. Machine 1.8 Composition.

[0027] The lift 1.1 is set on the basis below the ground level; the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com