Car bumper dismantling device

A bumper and car technology, applied in the field of car bumper disassembly devices, can solve the problems of high work intensity, low production efficiency, backward equipment, etc., so as to save disassembly time, reduce the consumption of manpower and material resources, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

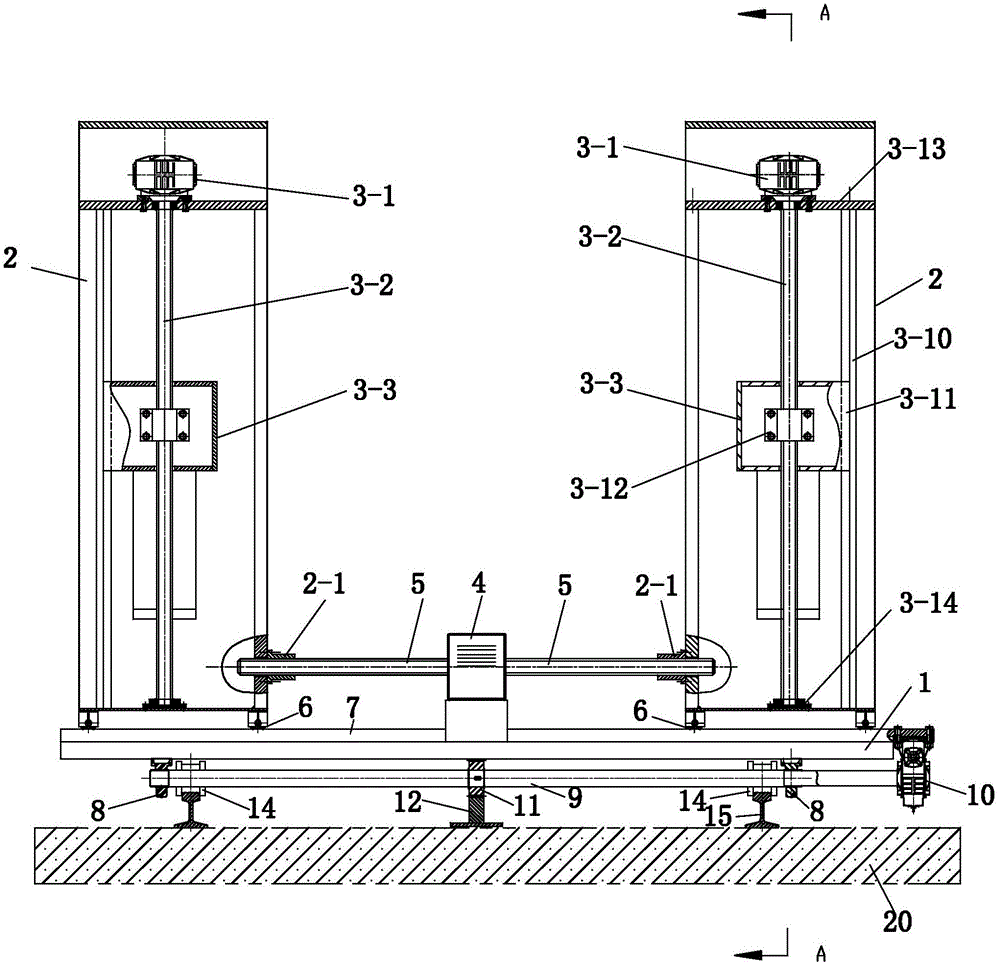

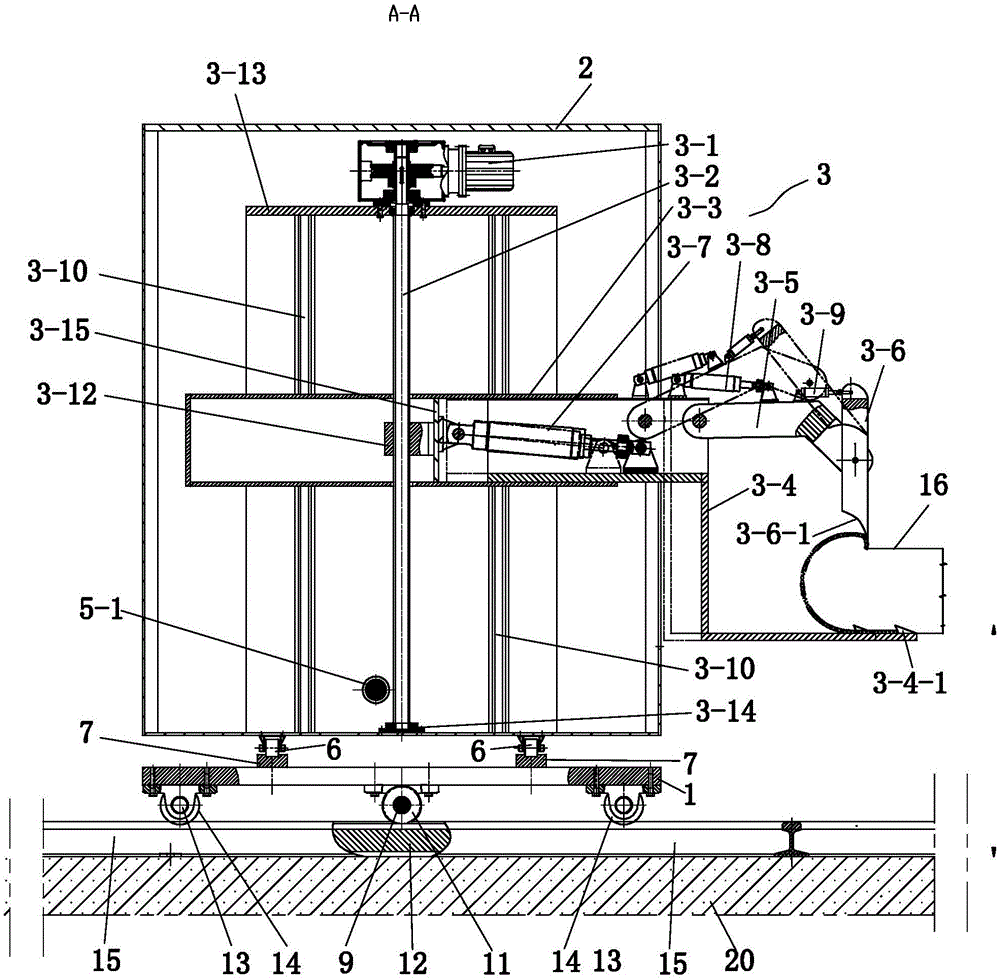

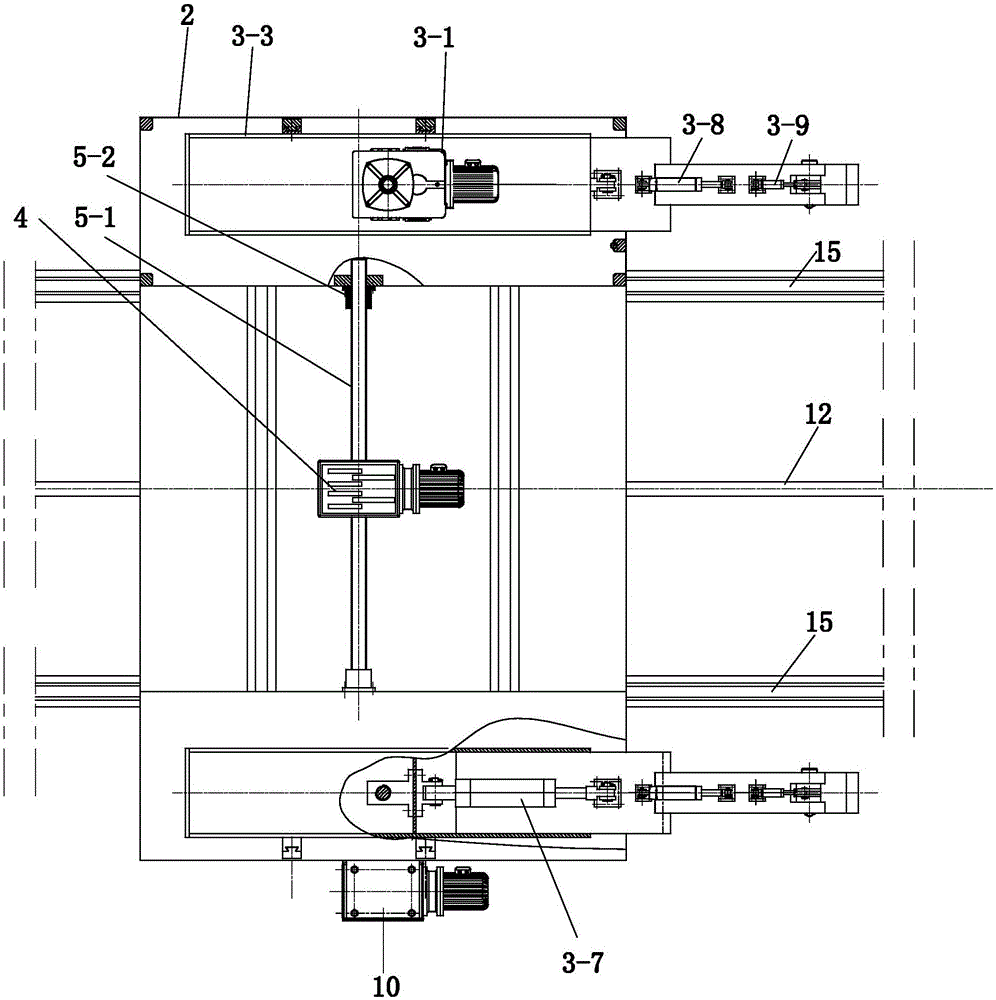

[0016] See Figure 1 to Figure 3 , the present embodiment has a support plate 1 and a dismantling box 2 respectively arranged on the left and right sides of the support plate 1 . Each of the two dismantling boxes 2 is provided with a manipulator 3 . The manipulator 3 has a lifting motor 3-1, a vertical screw mandrel 3-2, a moving frame 3-3, a support arm 3-4, a pressing arm 3-5, a grabbing arm 3-6, a support arm hydraulic cylinder 3-7, Press arm hydraulic cylinder 3-8, grab arm hydraulic cylinder 3-9 and vertical guide rail 3-10. A shelf 3-13 is fixed on the upper part of the dismantling box 2, the lifting motor 3-1 is fixed on the shelf 3-13, the bottom plate of the dismantling box 2 is provided with a bearing seat 3-14, and the vertical The upper end of the screw mandrel 3-2 is connected with the output shaft of the lifting motor 3-1, and the lower end is supported by the bearing block 3-14. The near vertical screw mandrel place in the middle part of described moving box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com