Belt Conveyor Low-Speed Shaft Coupling Disassembly Tool and Its Using Method

A coupling and low-speed shaft technology, which is applied in the field of belt conveyor maintenance tools, can solve problems such as long disassembly time and difficult maintenance of the sealing device of the reducer, and achieve the effects of reducing production costs, saving maintenance time, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

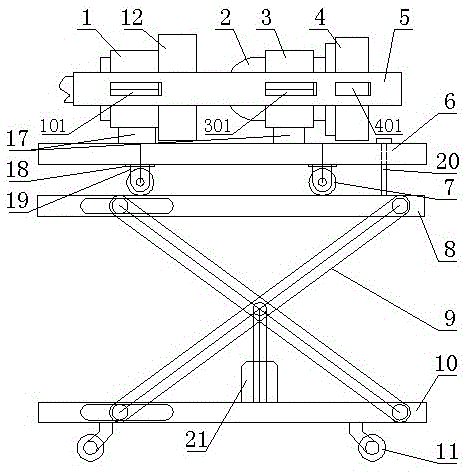

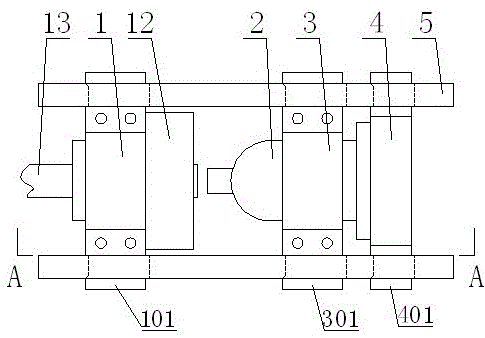

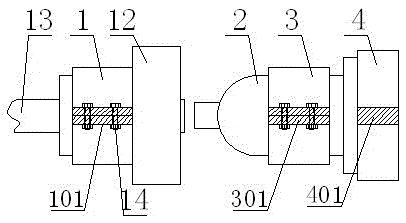

[0037] As shown in the figure, the disassembly tool for the low-speed shaft coupling of the belt conveyor consists of an arc-shaped splint 1 for the upper and lower couplings, a jack 2, an arc-shaped splint 3 for the upper and lower jacks, a bending-resistant beam plate 4, and a tensile arm 5. The support block 17 of the horizontal mobile platform is formed with a vertical lifting trolley. Among them, the upper and lower shaft couplings use arc-shaped splints 1, and the two sides are respectively provided with wing plates 101, which are formed by forging and pressing, and are used for relatively clamping on the inner side of the shaft coupling 12 and closely adhering to the inner side of the shaft coupling 12. . The jack 2 is used to be arranged outside the shaft coupling 12 and keep coaxial with the low-speed shaft 13 of the belt conveyor. The upper and lower jacks use arc-shaped splints 3, and the two sides are respectively provided with wing plates 301, which are used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com