End-of-life vehicle disassembly line

A technology for scrapped cars and car storage platforms, which is applied to the recycling of scrapped vehicles, the removal of motor vehicles, and solid waste. It can solve the problems of low automation, low efficiency of transportation and dismantling, and achieve high dismantling efficiency and easy management. And adjust, improve dismantling efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

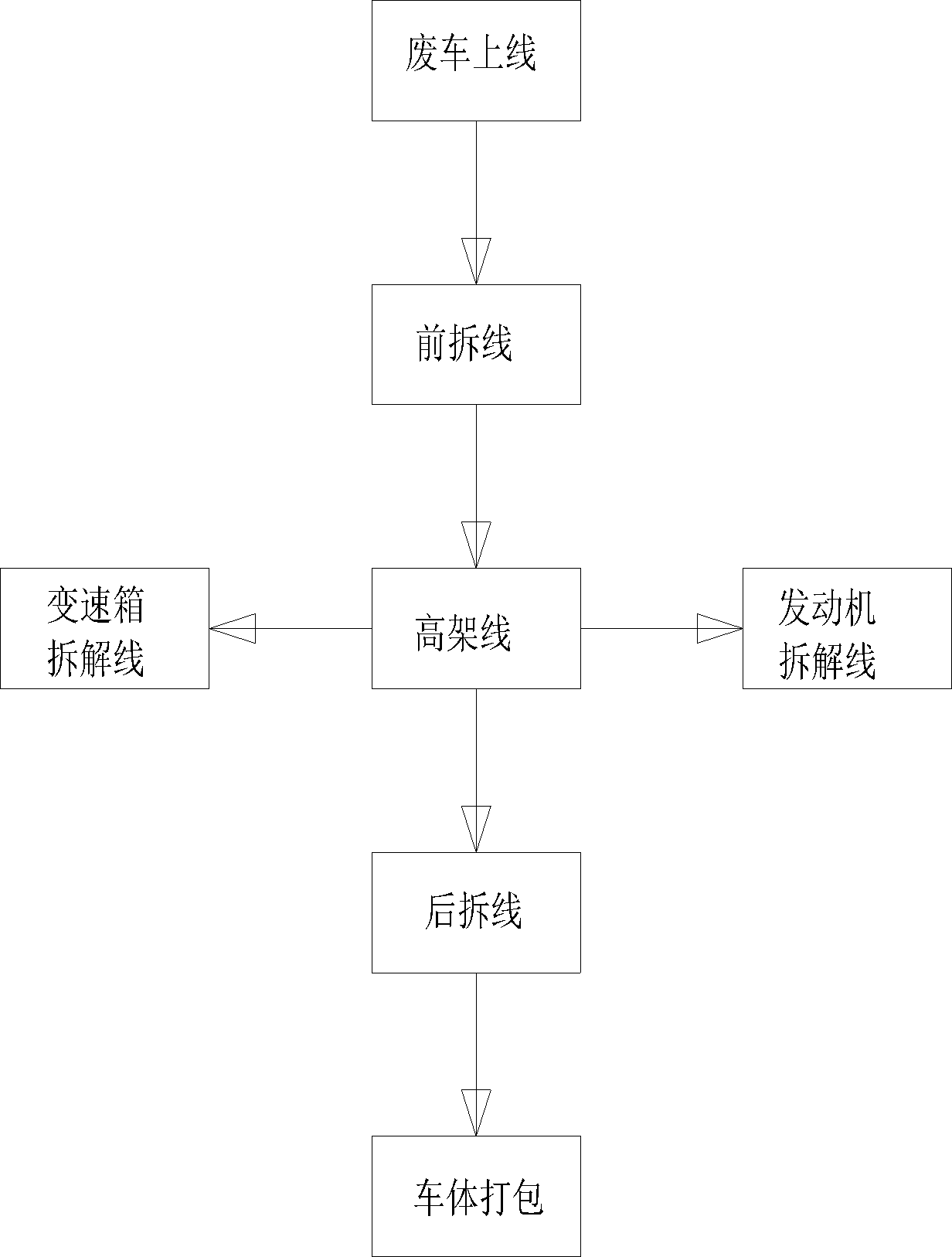

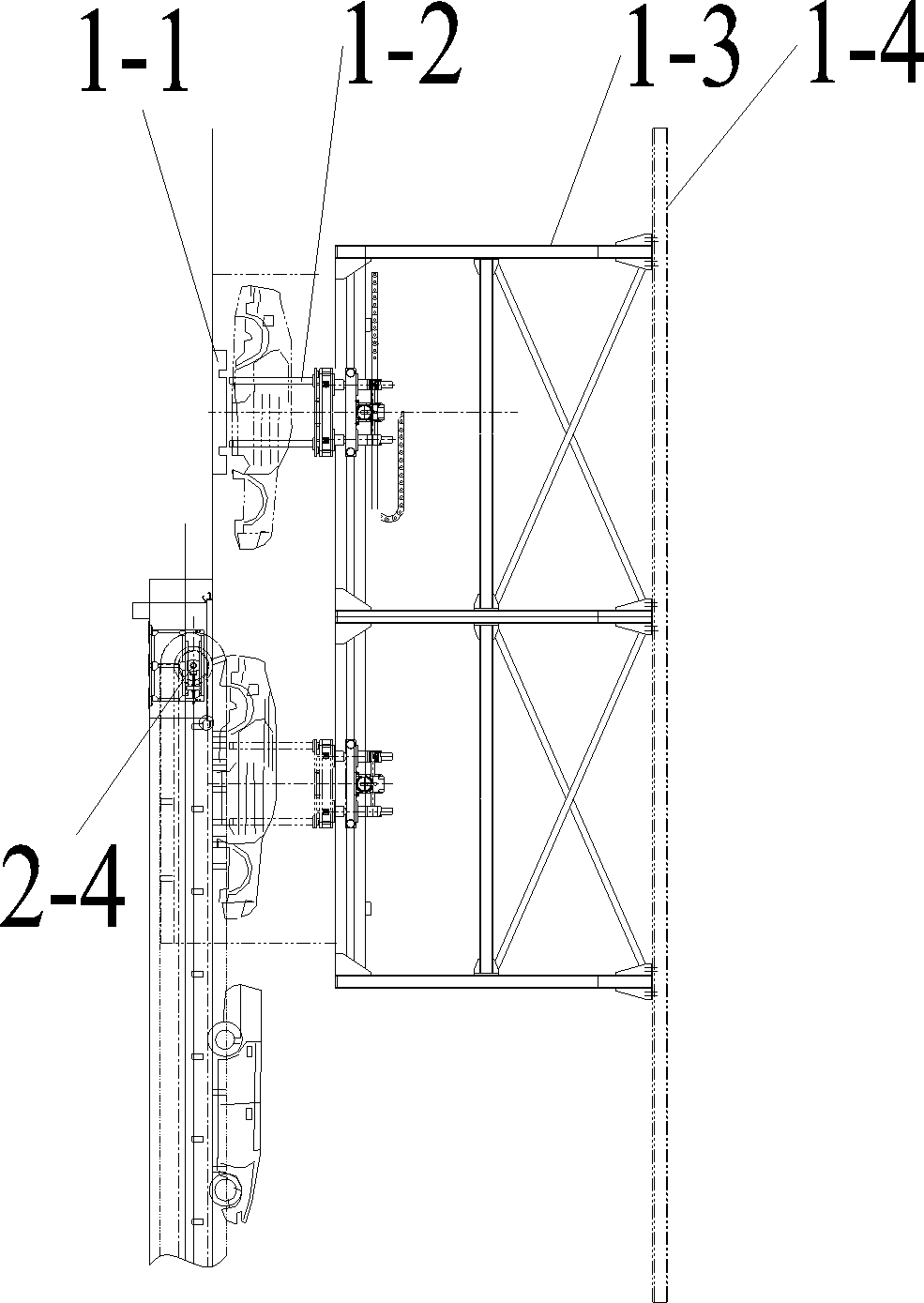

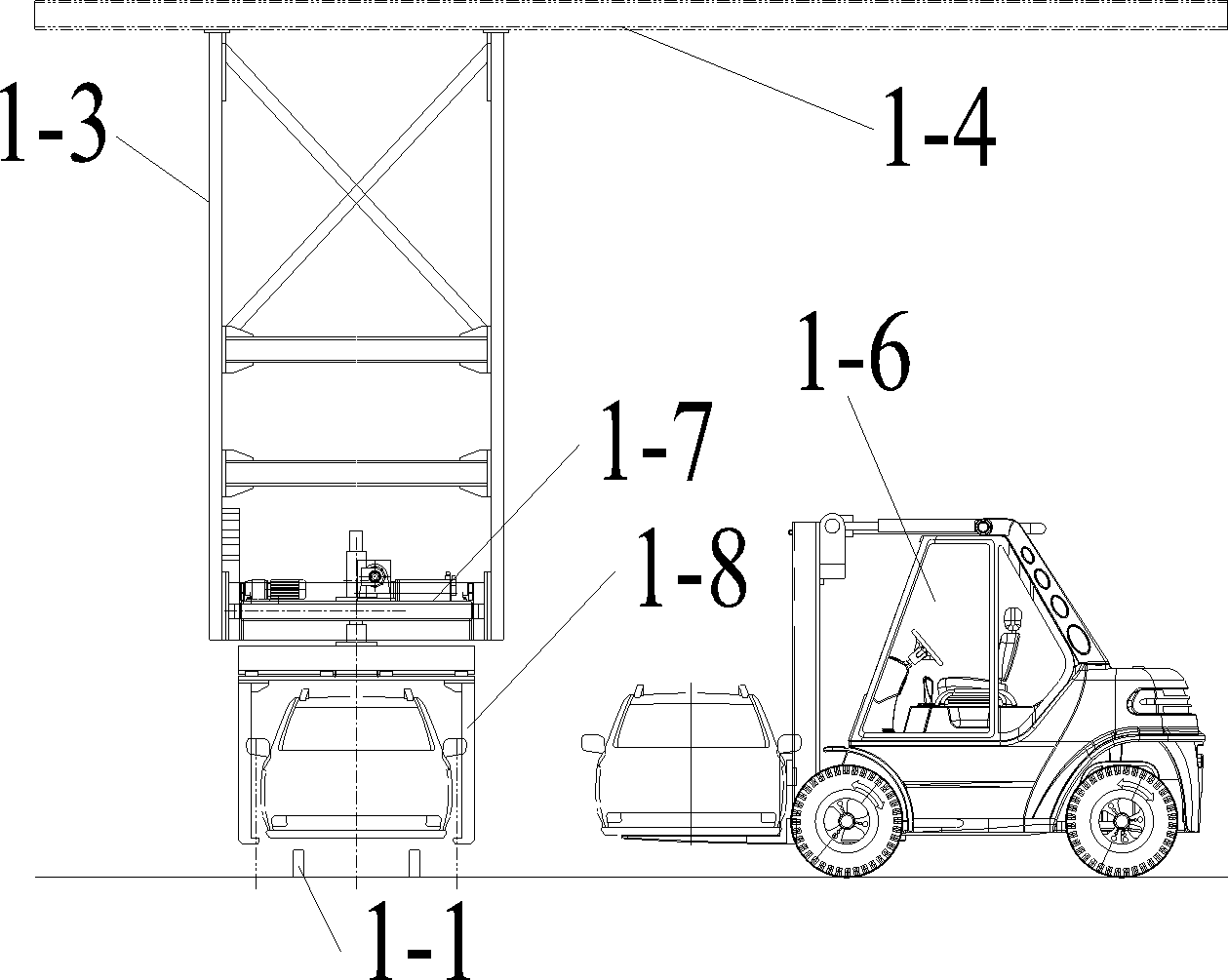

[0064] like figure 1 As shown, a scrapped car dismantling line of the present invention is configured according to the conveying direction of scrapped cars. Work and transport the scrapped cars to the elevated conveying system. The elevated conveying system completes the dismantling of the scrapped cars and transports the scrapped cars to the rear dismantling conveying system. The rear dismantling conveying system completes the packaging of the scrapped cars; , Elevated conveying system and rear demolition conveying system are connected with PLC module. The scrapped car dismantling line is mechanized operation, PLC module control, dynamic automatic dismantling, high dismantling efficiency; and each sub-system is set to facilitate the layout of the whole dismantling line, each sub-system has a clear division of labor, with the delivery of scrapped cars , complete the disassembly of the corresponding parts in sequence, the disassembly efficiency is high, and it is also convenie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com