Lifting and flipping machine for scrapped car dismantling

A scrapped car, dual-use technology, applied in cranes, transportation and packaging, load hanging components, etc., can solve the problems of not meeting general requirements, single-function lifts and turning machines, etc., to achieve reasonable structure and versatility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

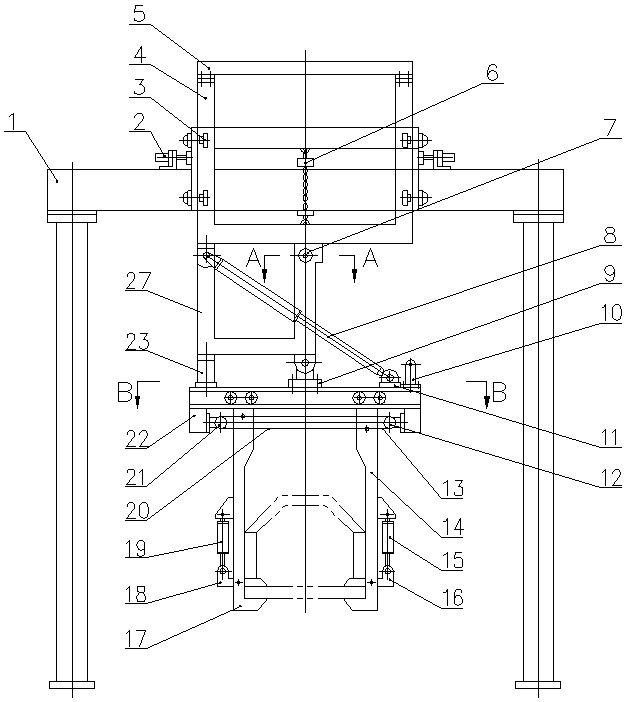

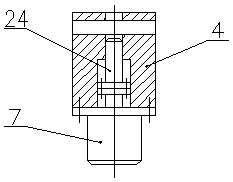

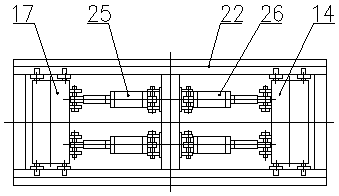

[0020] see Figure 1-Figure 3 , the present invention relates to a dual-purpose machine for dismantling, lifting and turning scrapped cars, which includes a frame 1, a locking mechanism 2, a guide wheel assembly 3, a lifting frame 4, a connecting beam 5, an electric crane 6, a turning and locking cylinder 7, Overturn cylinder 8, first support seat 9, overturn locking tongue 10, second support seat 11, right pulley assembly 12, right wire rope 13, right hanging foot assembly 14, right presser foot cylinder 15, right presser foot 16, left hanging foot Component 17, left presser foot 18, left presser foot oil cylinder 19, left wire rope 20, left pulley assembly 21, overturn frame 22, limit seat 23, locking pin 24, left hanging foot moving oil cylinder 25, right hanging foot moving oil cylinder 26, Connecting frame 27, electro-hydraulic power source, console and connecting electro-hydraulic pipeline.

[0021] The frame 1 is provided with four vertical guide grooves, the lift fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com