Scraped car resource recovery system with dust-removal device

A technology for scrapped automobiles and resource recovery, applied in the field of scrapped automobile resource recovery systems, can solve problems such as operator and environmental impact, dust, etc., and achieve the effect of reducing dust, reducing costs, and realizing recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

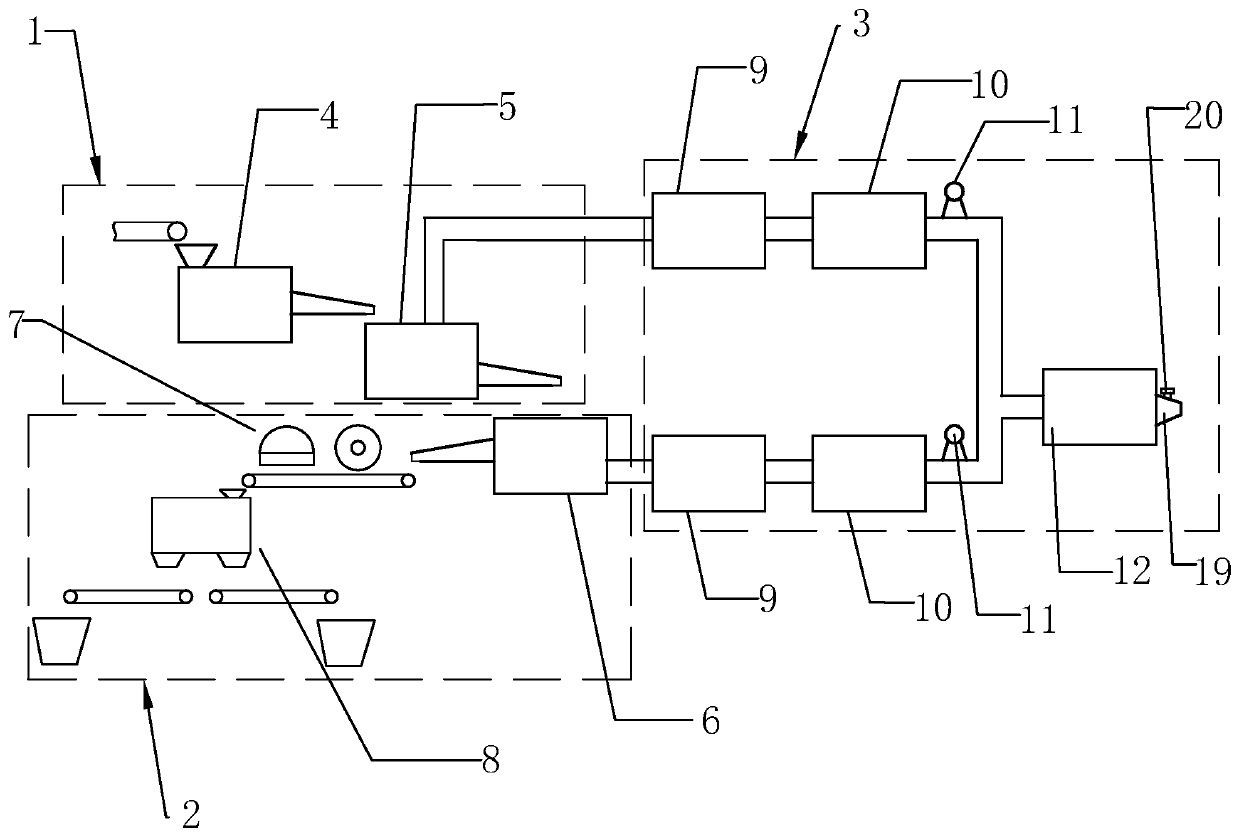

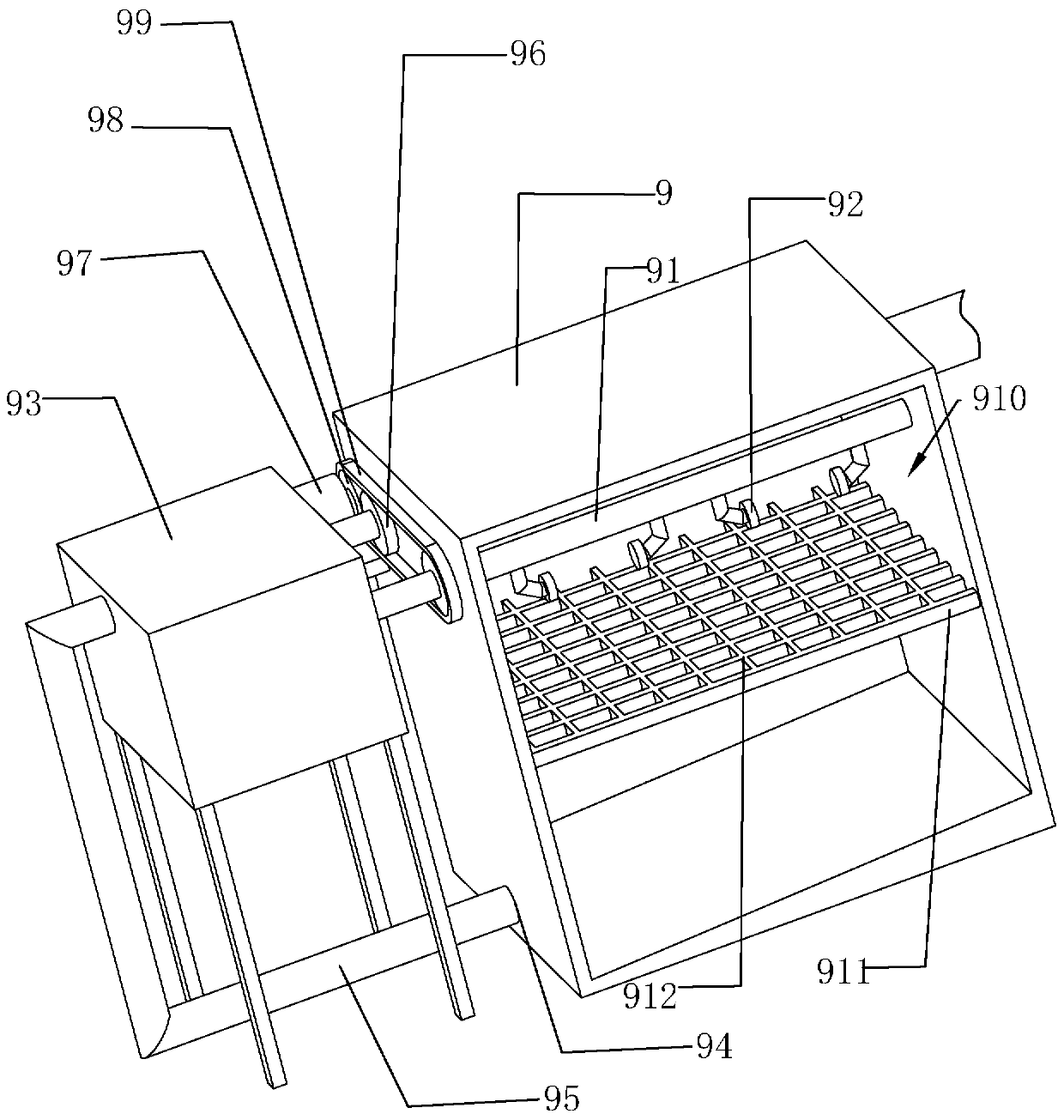

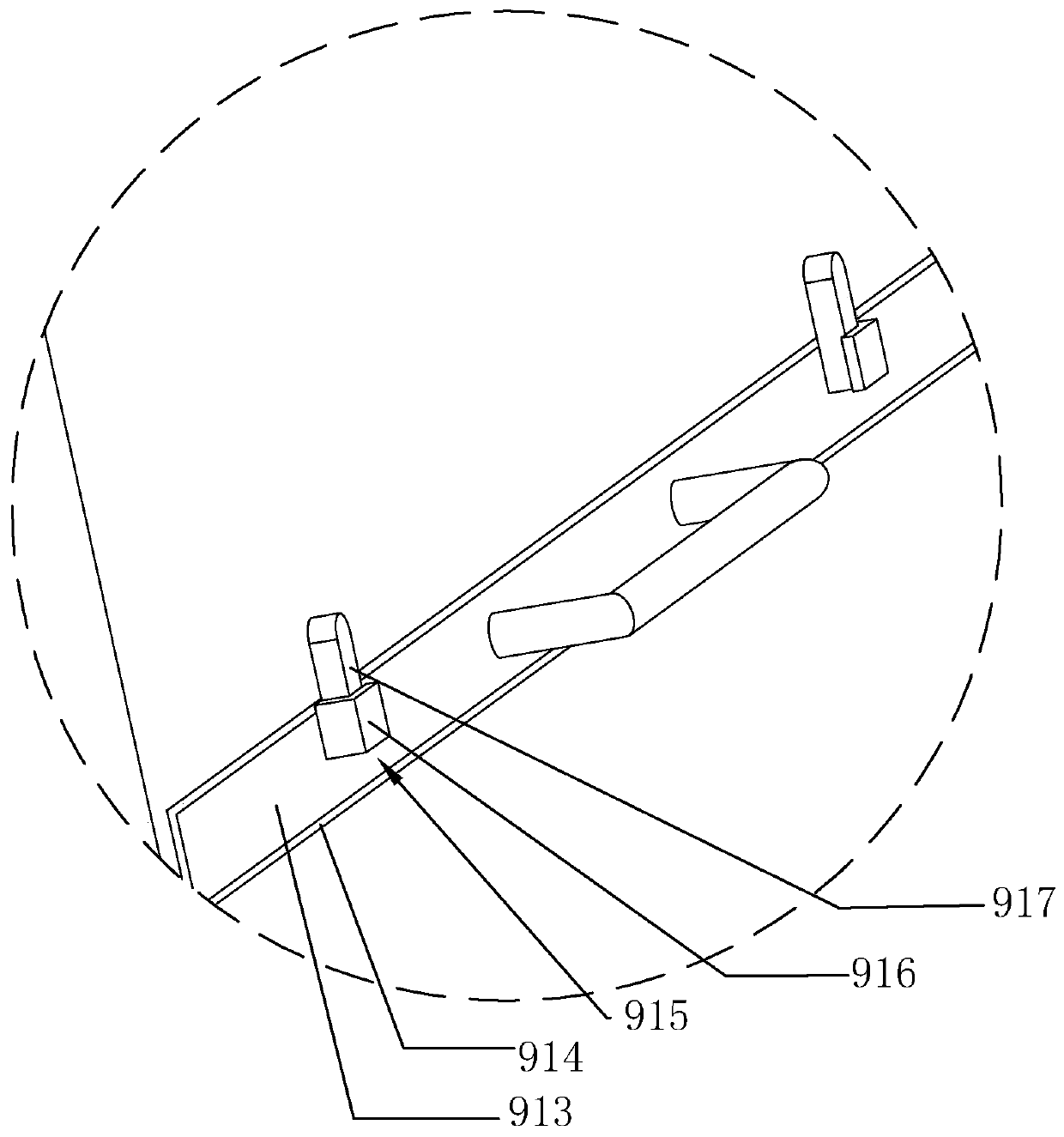

[0033] Such as figure 1 As shown, it is a scrapped vehicle resource recovery system with a dust removal device disclosed in the present invention, including a crushing unit 1 and a screening unit 2, the crushing unit 1 includes a double-shaft shredder 4 and a crusher 5, and the screening unit 2 includes a vibrating screen machine 6, a magnetic separator 7 and an eddy current separator 8 connected in sequence, and a dust removal mechanism 3 is provided on one side of the vibrating screen machine 6 and the crusher 5, and the dust removal mechanism 3 includes a settling chamber 9, two settling chambers One side of the chamber 9 is connected to the vibrating screen machine 6 and the crusher 5 respectively, and the other side of the settling chamber 9 is connected to the dust removal tower 10 , and the side of the dust removal tower 10 away from the settli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com