Method for evaluating manufacturing service capability of socialized manufacturing system for order demand

A technology of manufacturing systems and service capabilities, applied in the manufacturing field, can solve the problems of inability to complete production tasks, bottlenecks of manufacturing resources and service capabilities, and idle resources of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

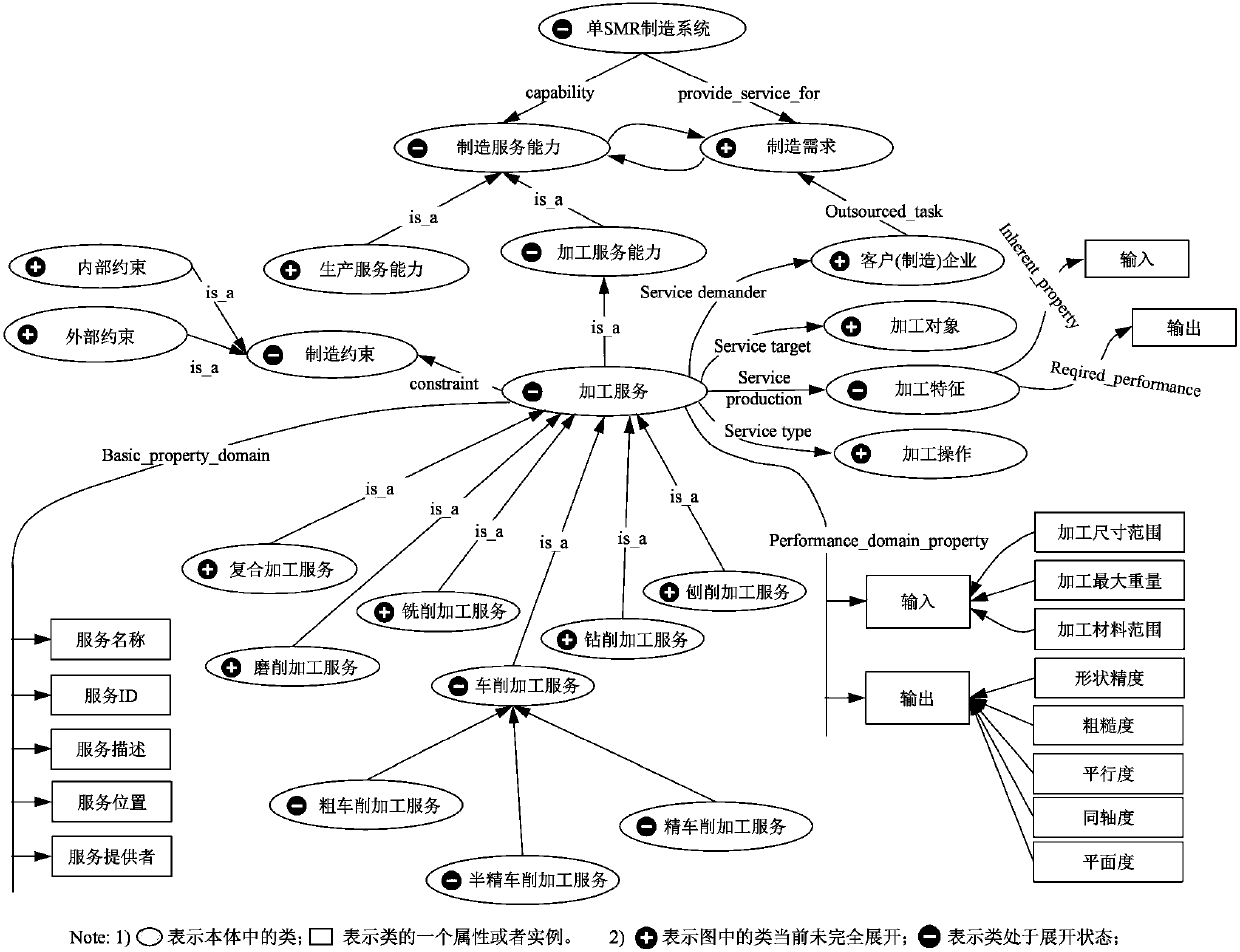

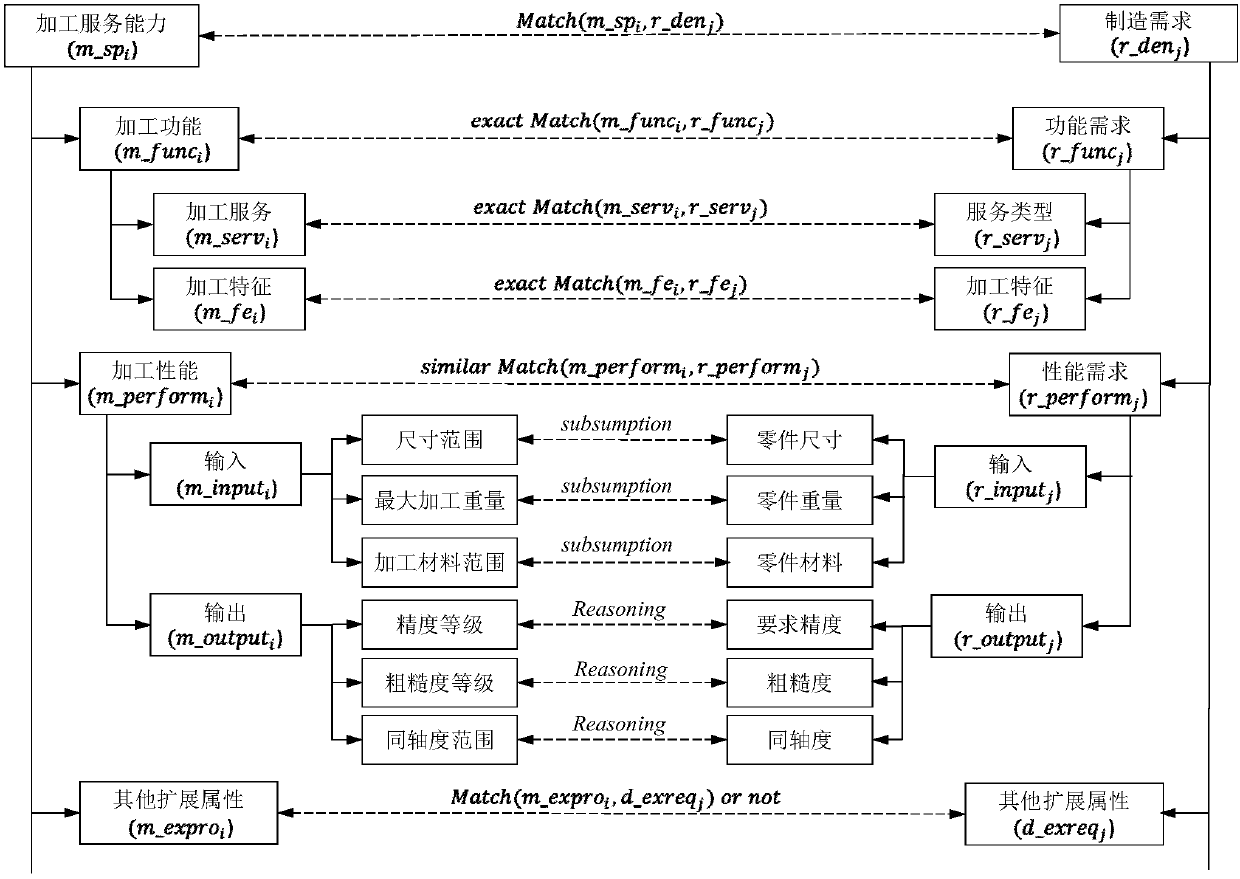

[0037] In the community manufacturing environment, the quantitative evaluation of the manufacturing service capabilities of the community manufacturing system is the basis for the release of social manufacturing resources. At the same time, it can also realize the automatic search and optimized matching of order requirements and manufacturing service capabilities based on this. In order to achieve the above objective, the present invention attempts to establish a quantitative evaluation method for the manufacturing service capability of a community manufacturing system oriented to order requirements. The following describes in detail the various details involved in the method for quantitative evaluation of manufacturing service capability in the present invention with reference to the drawings.

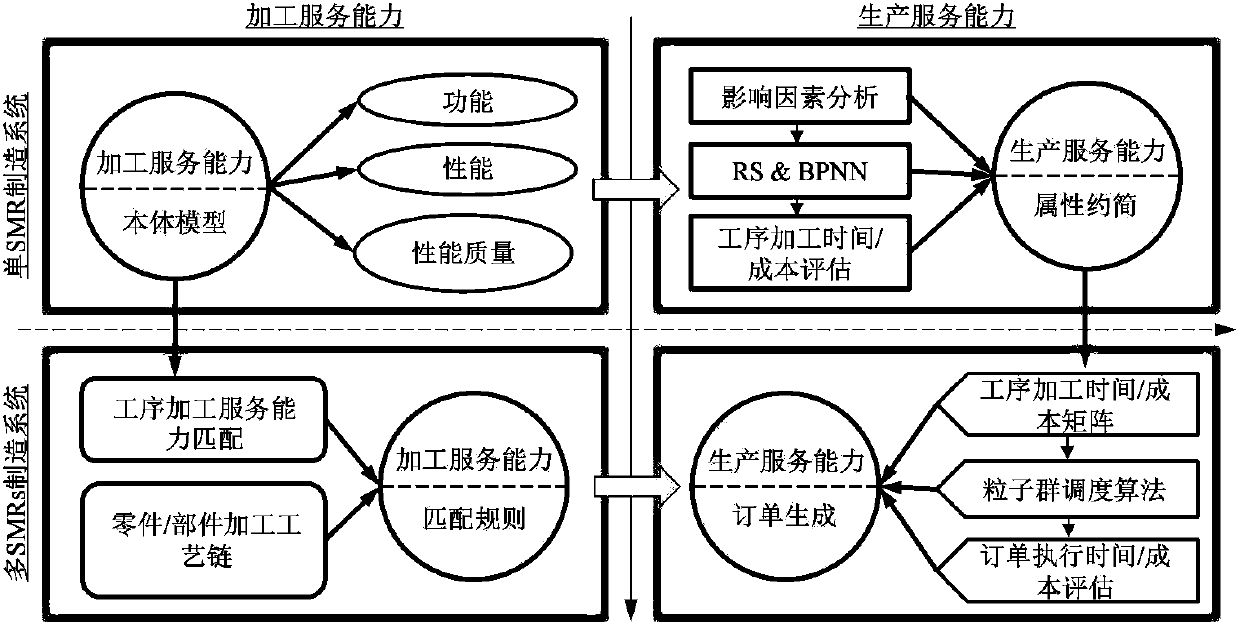

[0038] See figure 1 The implementation logic of the manufacturing service capability evaluation model involved in the present invention mainly includes the following four steps: 1) By def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com