Manufacturing resource recommendation method and system on basis of Web services

A recommendation method and technology for manufacturing resources, applied in manufacturing computing systems, resource allocation, transmission systems, etc., can solve problems such as limited manufacturing resource scale and production capacity, declining service quality, and lack of understanding, to eliminate imbalances and achieve load The effect of balancing and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

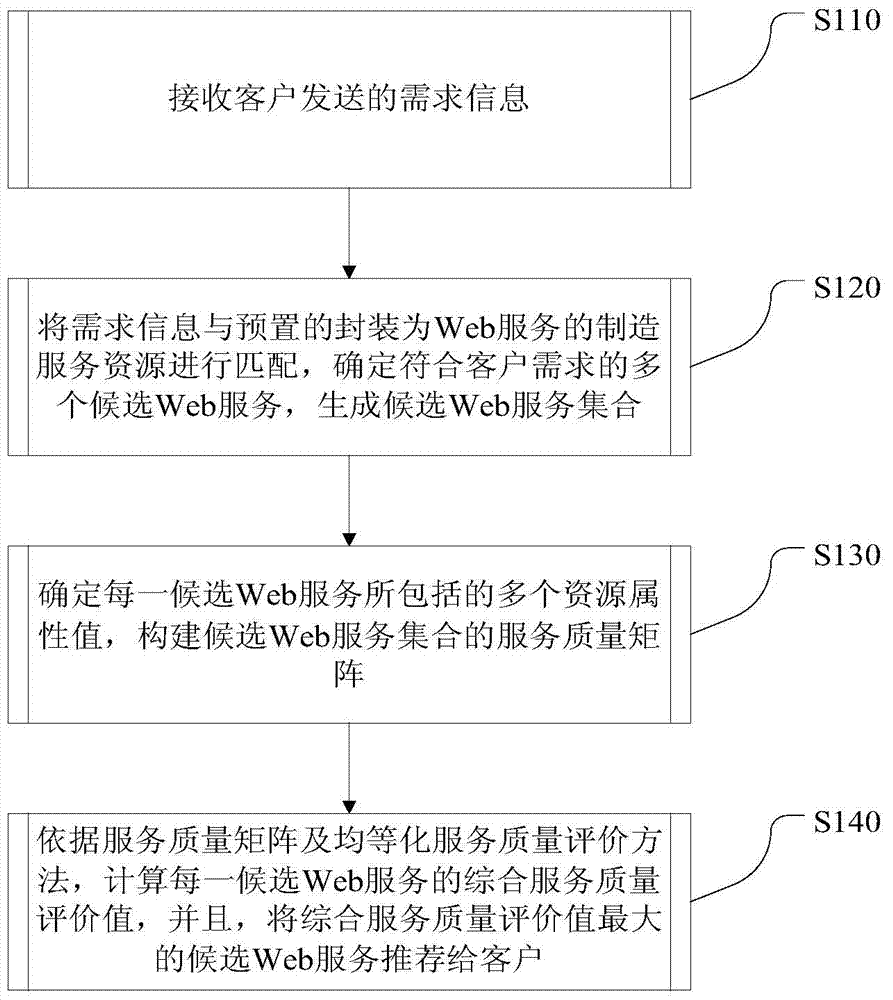

[0032] refer to figure 1 , figure 1 It is a flow chart of the steps of an embodiment of the method for recommending manufacturing resources based on Web services in the present invention, including the following steps:

[0033] Receiving step S110, receiving the demand information sent by the customer;

[0034] The candidate Web service set generation step S120 is to match the demand information with the preset manufacturing service resources packaged as Web services, determine multiple candidate Web services that meet customer needs, and generate a candidate Web service set;

[0035] Quality of service matrix generating step S130, determining multiple resource attribute values included in e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com