Intelligent truck scale internet-of-things system

An Internet of Things system and smart car technology, applied in the direction of comprehensive factory control, comprehensive factory control, weighing equipment testing/calibration, etc., can solve the problem that the loss cannot be fundamentally solved, the weighing failure is not easy to be detected in time, and the hidden dangers of healthy operation and other issues, to achieve the effect of saving resources and waste, improving the overall service level and image, and controlling and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

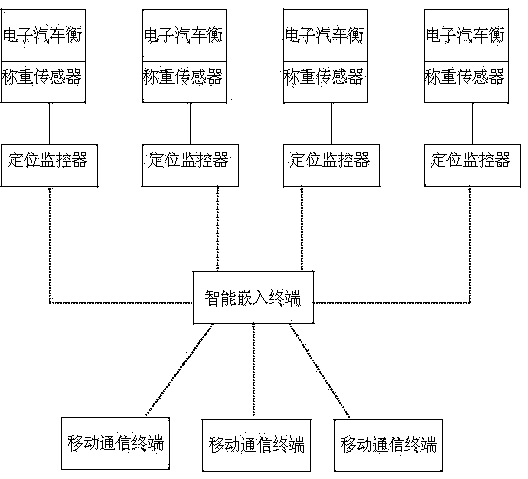

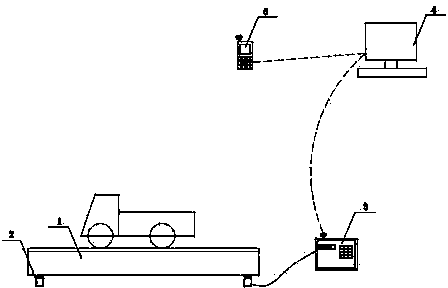

[0019] like figure 1 and figure 2 As shown, the present invention includes an electronic truck scale 1 , a load cell 2 , a positioning monitor 3 , an intelligent embedded terminal 4 , and a mobile communication terminal 5 . The electronic truck scale 1 equipped with the load cell 2 is connected with the positioning monitor 3 through the corresponding interface.

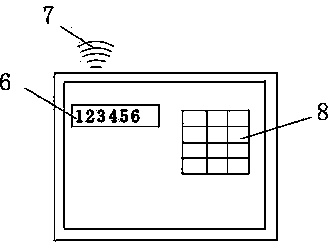

[0020] Positioning controller 3 such as image 3 As shown, including a chip with a SIM card, and a display 6 connected to the chip, a control panel 8 and an antenna 7, the positioning monitor 3 collects and analyzes the operation data of the electronic truck scale in real time, stores the information in the SIM card and displays the information on the display. 6 is displayed. Then it is controlled by the control panel, connected to the mobile communication network through the antenna 7 and wirelessly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com