Online 3D printing customization system and method

A 3D printing and customized system technology, applied in the direction of digital output to printing unit, data processing application, sale/rental transaction, etc., can solve the problems of inability to meet speed requirements, slowness, redundant system calculation, etc., to save storage space and computing time, overcoming the effect of low computational accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

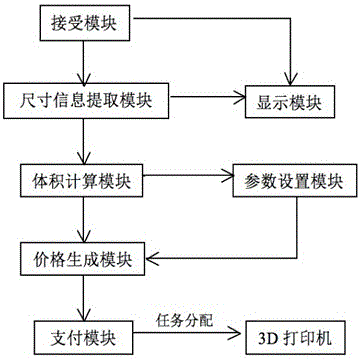

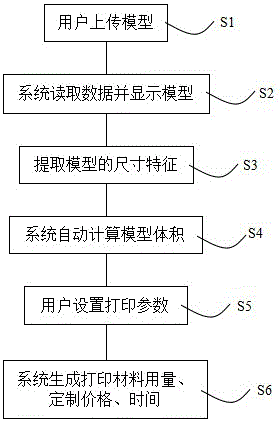

[0034] The present invention firstly provides an online 3D printing customization system, such as figure 1 As shown, it includes a receiving module, a size information extraction module, a volume calculation module, a parameter setting module, a price generation module, a payment module and a 3D printer.

[0035] Wherein, the receiving module is used to receive and read the 3D model file uploaded by the user, wherein the 3D model is a 3D model generated by any 3D modeling software, and the format of the model file includes STL, OBJ, DAE, WRL, X3D, etc.

[0036] The display module is used to display the 3D model uploaded by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com