Additive manufacturing resource dispatching system based on cloud computing and corresponding method

An additive manufacturing and resource scheduling technology, applied in the transmission system, electrical components, etc., can solve the problems of limited printing resources and uneven distribution of printing resources, and achieve the effect of high reliability and high scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

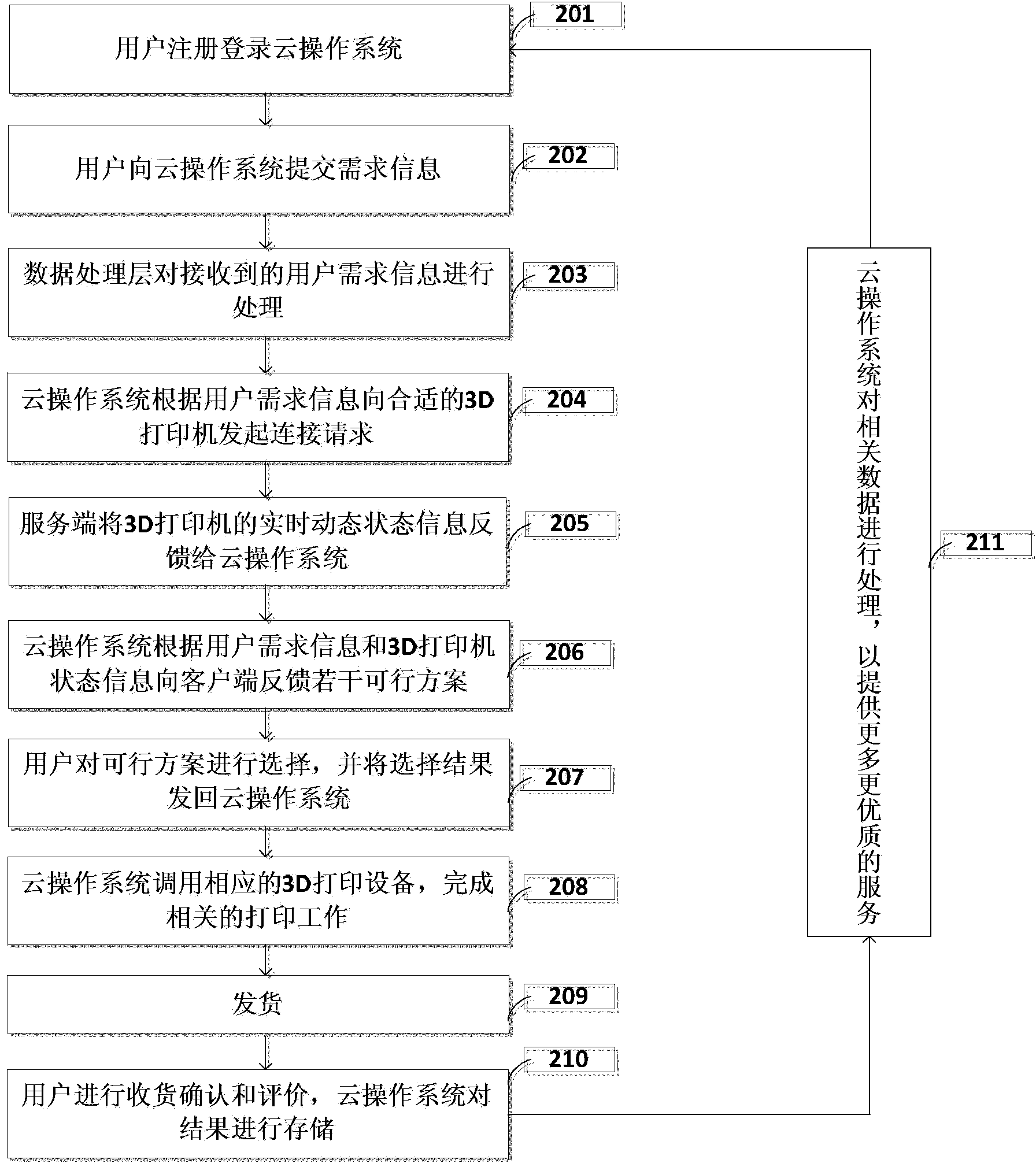

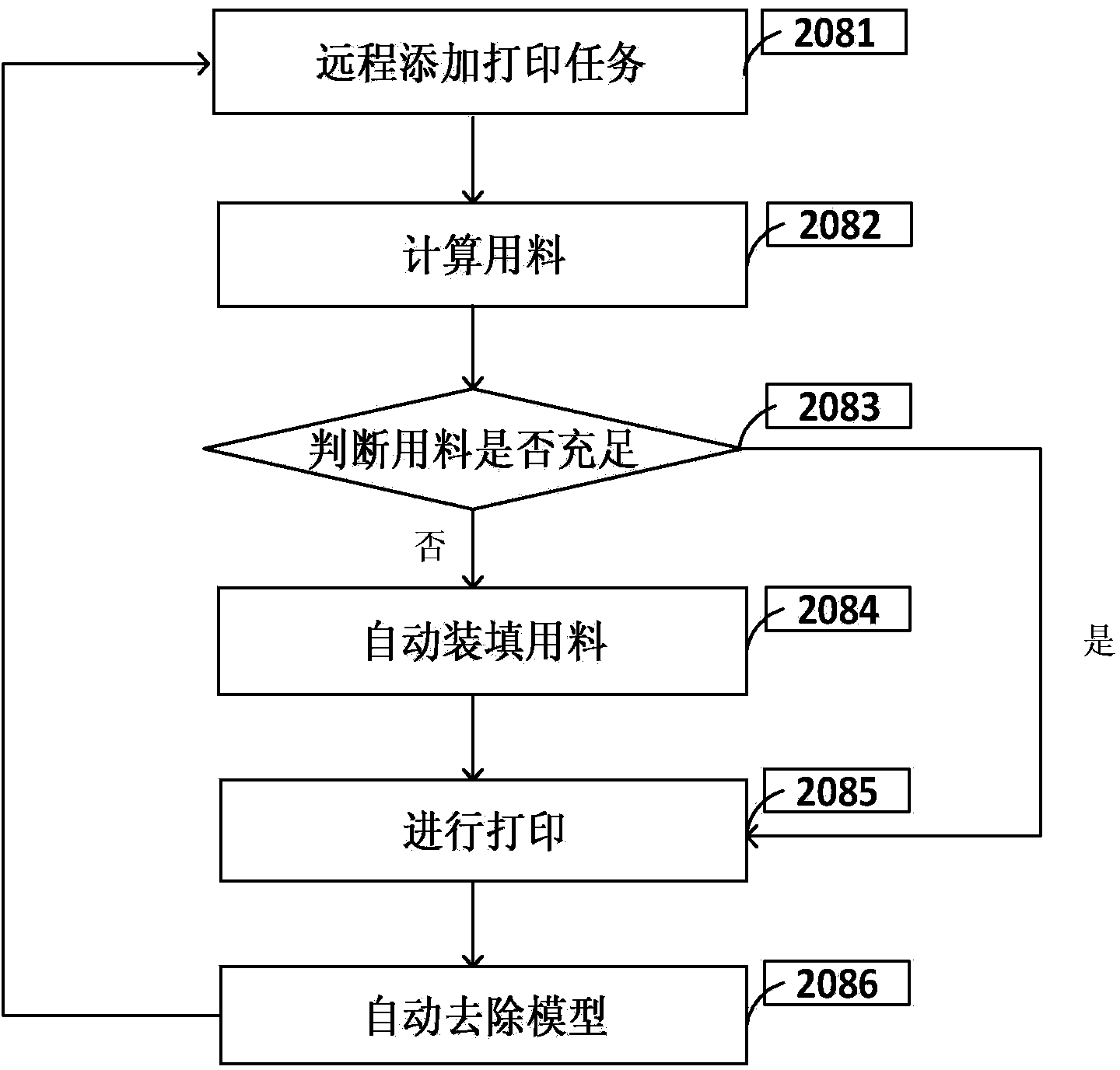

[0028] The present invention proposes a cloud computing-based additive manufacturing resource scheduling system. On the one hand, the system extensively collects personalized demand information from customers, and maximizes the use of limited 3D printing resources to meet the needs of a large customer group; on the other hand On the one hand, it intelligently manages and invokes 3D printing resources through the cloud operating system, providing customers with faster and better services.

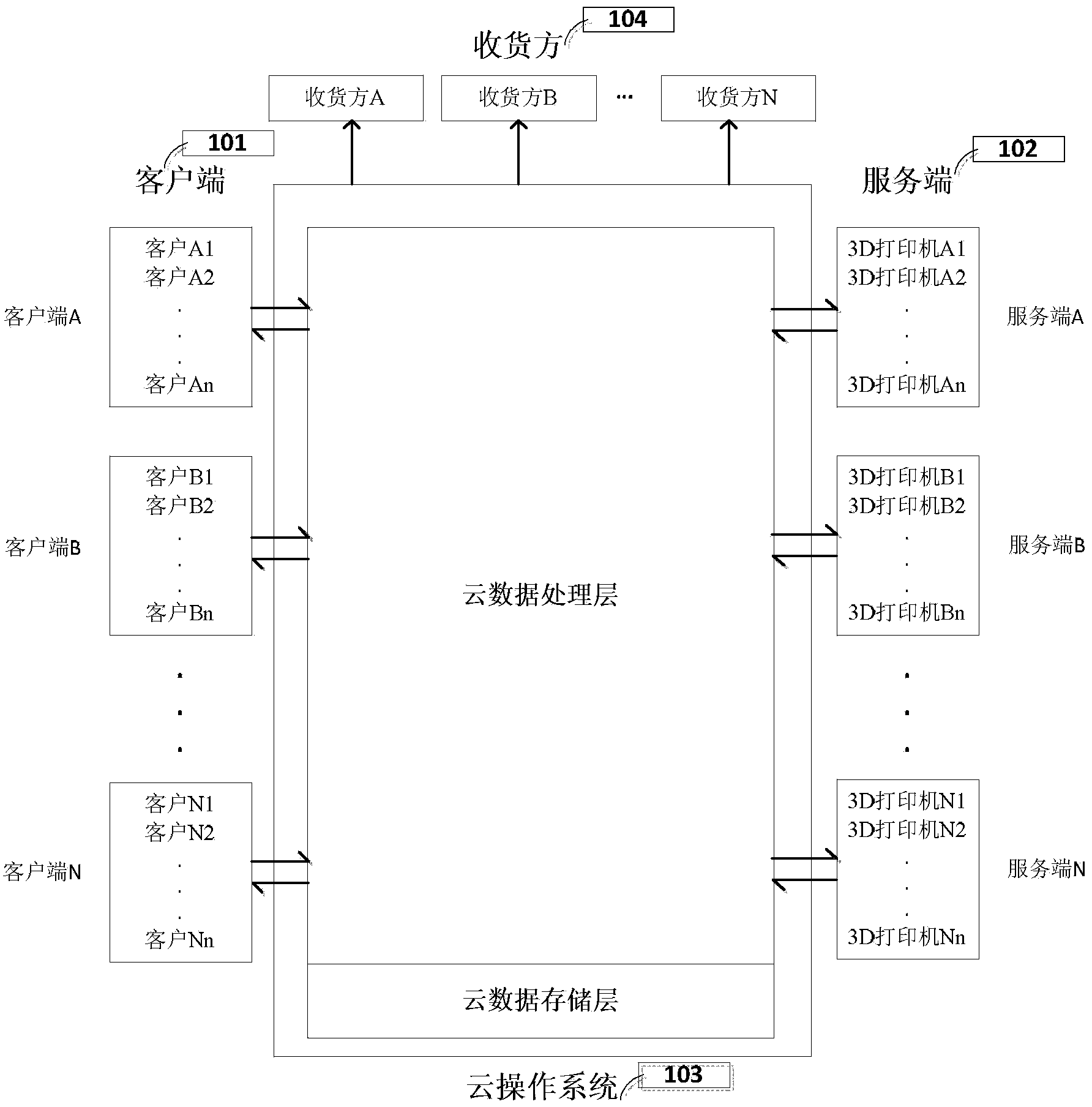

[0029] figure 1 It is a structural diagram of an additive manufacturing resource scheduling system according to an embodiment of the present invention, such as figure 1 As shown, the system includes: client 101, server 102, cloud opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com