Optimal Method for Load Distribution of Ethylene Cracking Furnace Group

A technology of ethylene cracking furnace and load distribution, which is applied in cracking, non-catalytic thermal cracking, instruments, etc., and can solve problems such as the inability to deeply and carefully evaluate the operating efficiency of the cracking furnace, the influence of the operating efficiency and benefits of the cracking device, and strong subjectivity. , to achieve the effects of wide adaptability and analogy, easy implementation, and reduced complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

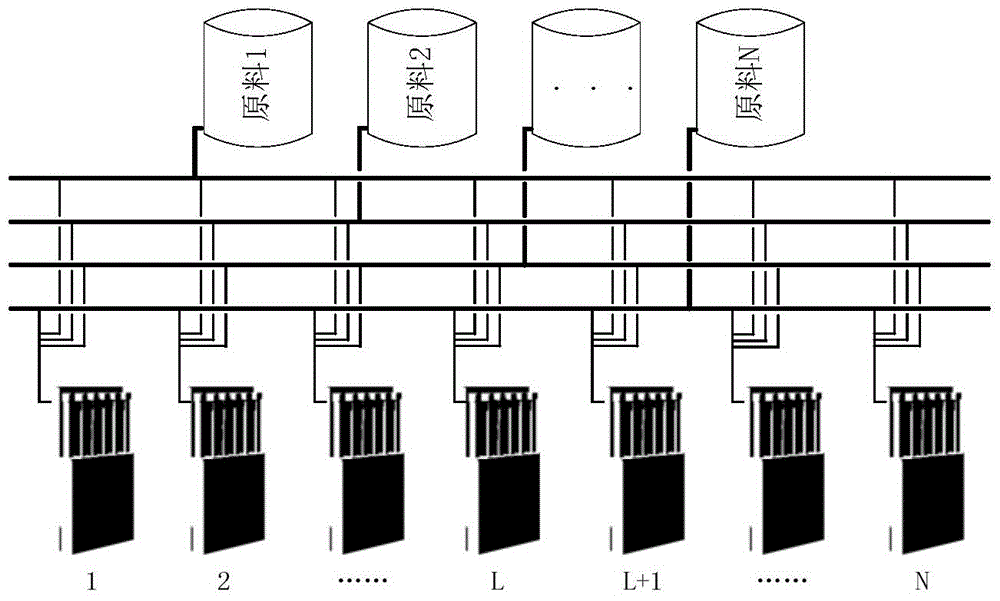

[0055] The load distribution optimization method of the ethylene cracking furnace group in this specific embodiment is an example of an ethylene cracking furnace group consisting of 14 cracking furnaces in an ethylene complex, including 5 Type I units, 1 Type II unit, and 1 Type III unit. , 3 IV-type and 4 V-type cracking furnaces, the schematic diagram is shown in figure 1 , but not limited to this.

[0056] The implementation of the load distribution optimization method for ethylene cracking furnaces includes the following steps:

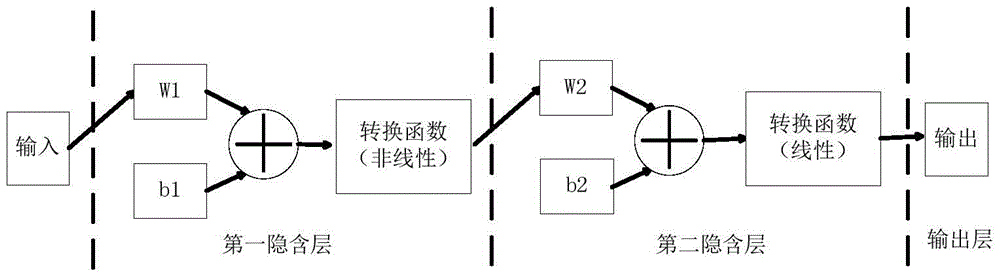

[0057] 1. Establish a prediction model for cracking product yield

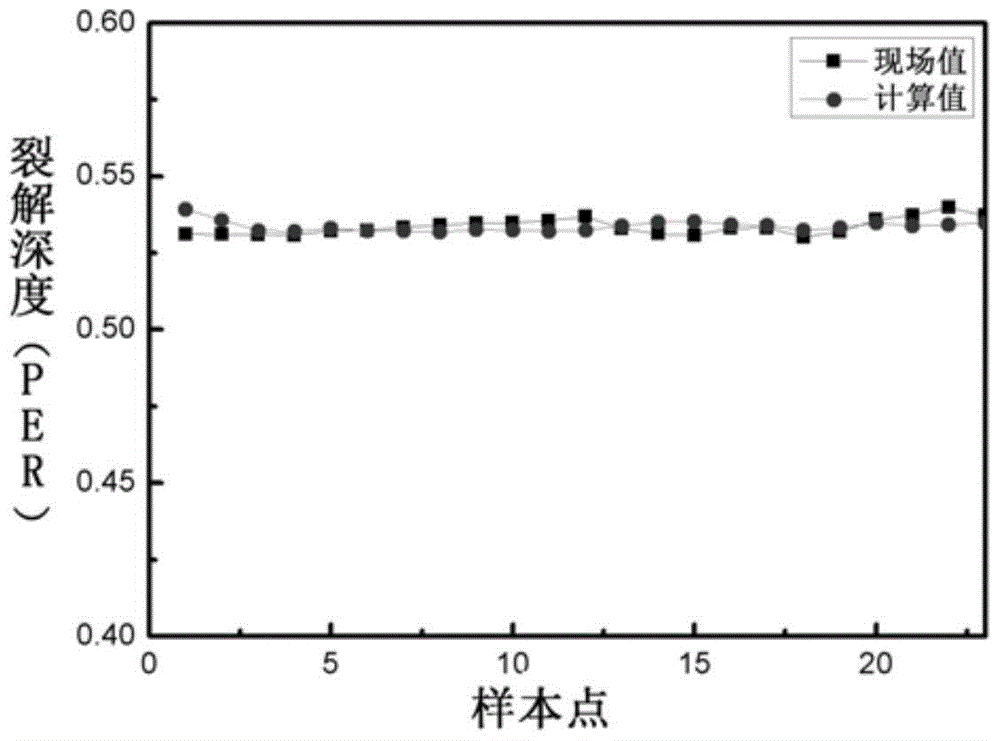

[0058] A neural network proxy model is used to construct key product yield prediction models for different cracking furnaces. The input variables of each cracking furnace include the outlet temperature of the radiant section (COT), the hydrocarbon feed load (F hc ), steam-hydrocarbon ratio (SHR) and volume of adiabatic section, etc.; output variables include key product yield, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com