Modular internal gear pump or modular motor

A technology of internal gear pumps and internal gears, which is applied in the direction of rotary piston pumps, intermeshing engines, pumps, etc., can solve the problems of poor versatility, and achieve the effects of compressed inventory, flexible and simple assembly, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will now be described in further detail in conjunction with the accompanying drawings and embodiments.

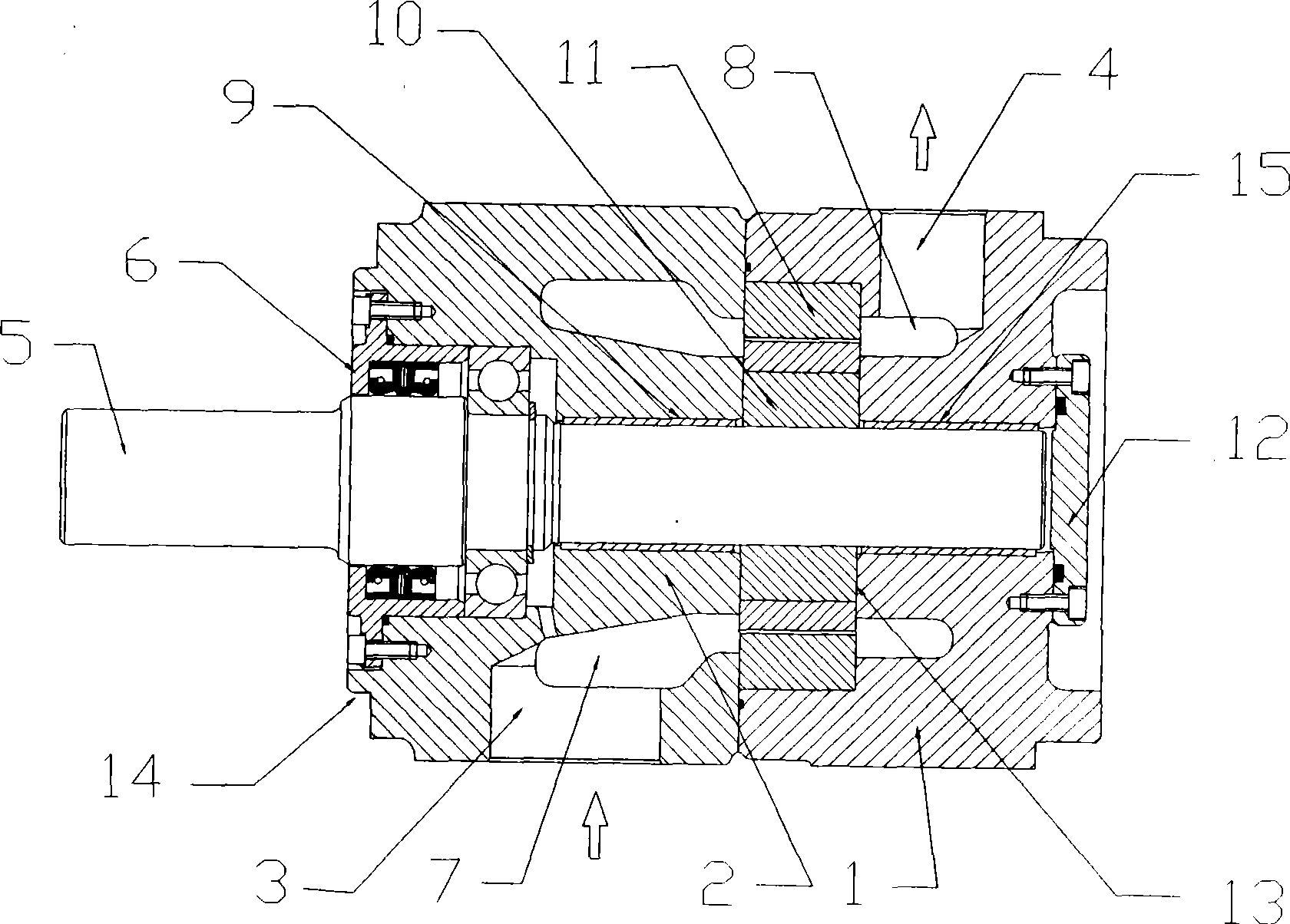

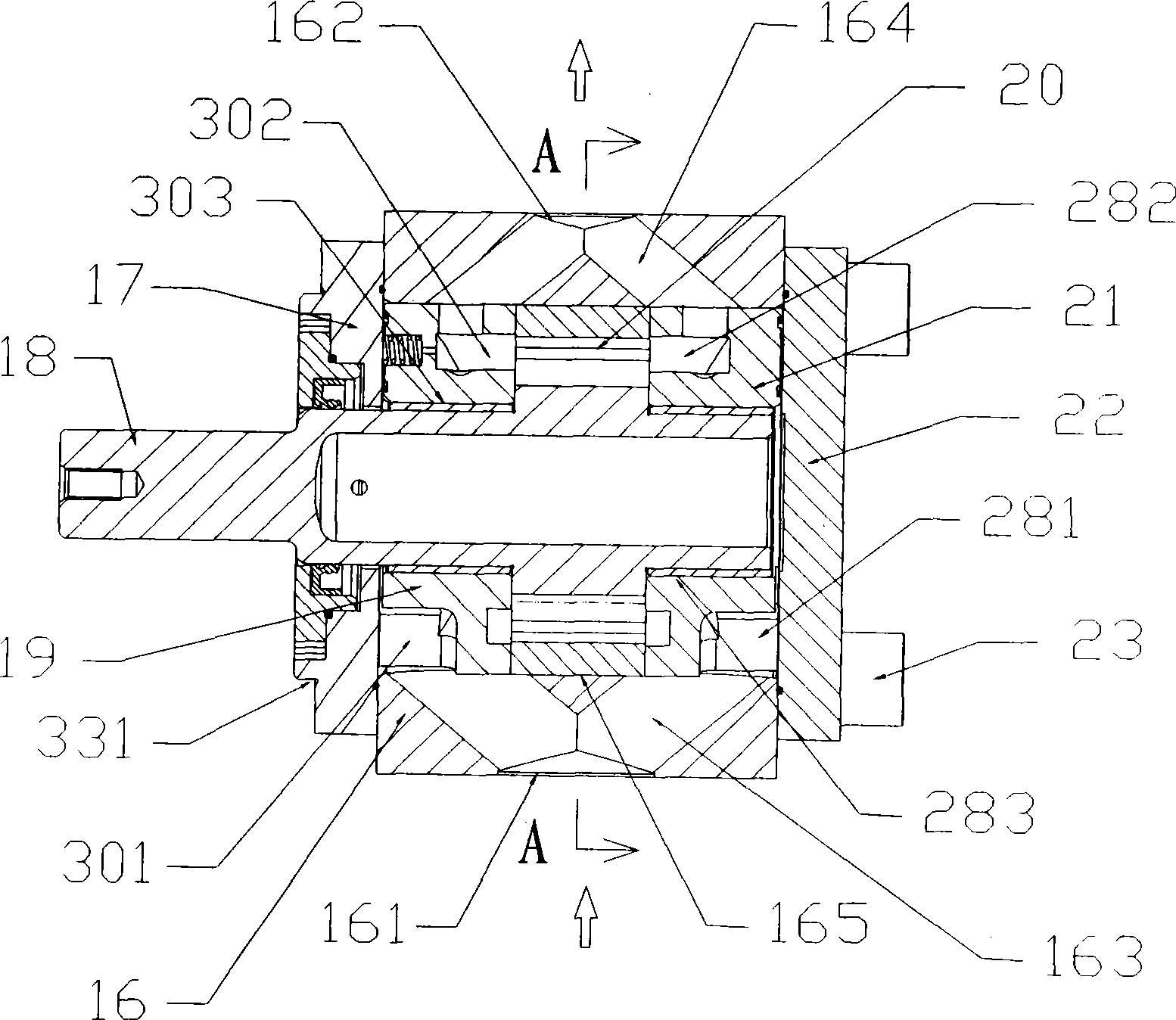

[0056] see figure 2 , 4 Schematic diagram of the structure of the present invention, the diagram shows that the modular internal gear pump or motor consists of a housing 16, an internal gear pair 20, an input shaft 18, a fixed bearing disc assembly 21, a floating bearing disc assembly 19, and a flange cover assembly 17 and the rear cover assembly 22, the flange cover assembly 17, the rear cover assembly 22 and the housing 16 are fixed in series by screws 23.

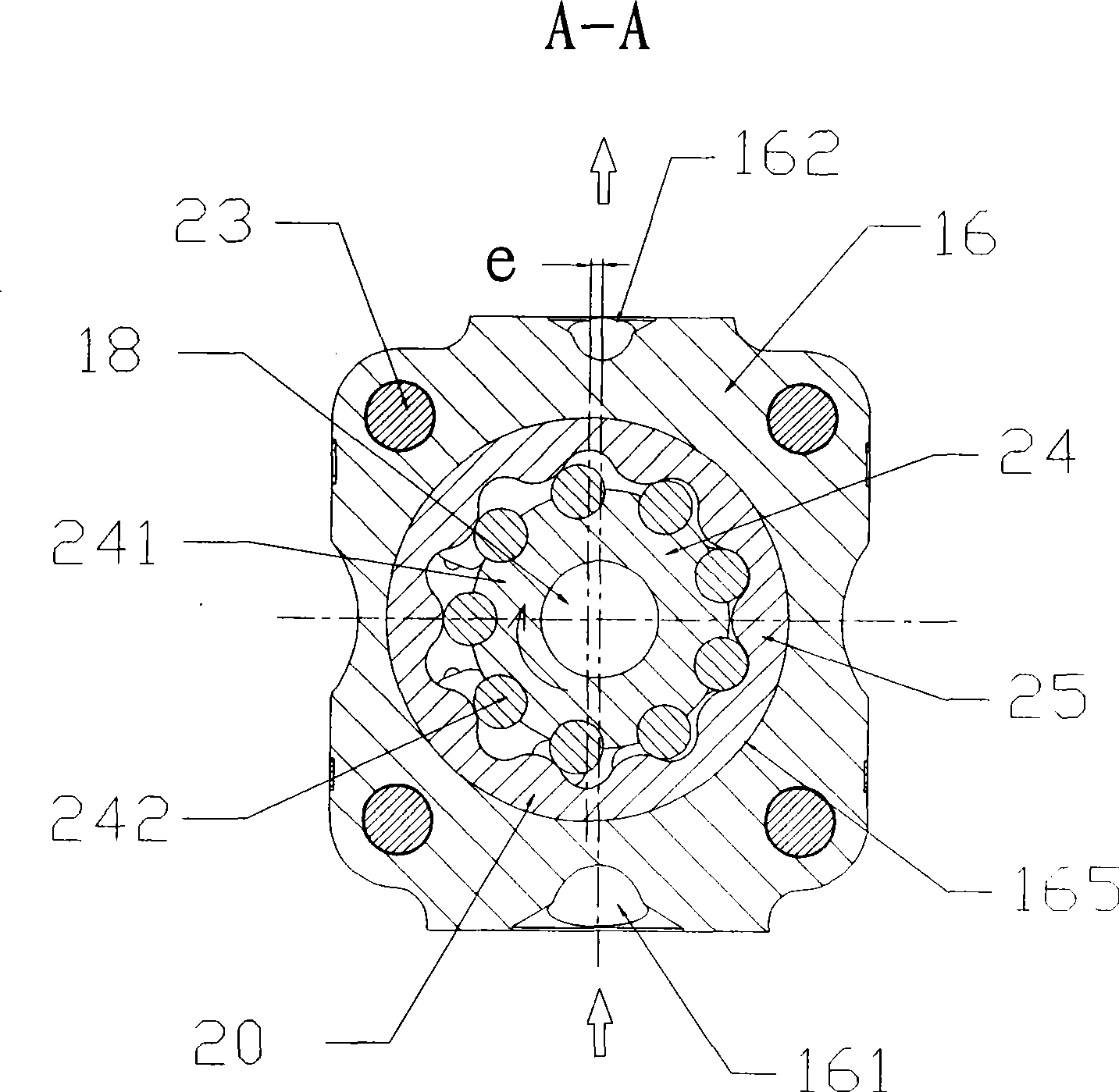

[0057] Please refer to Figure 5 , the housing 16 is a thick-walled cylindrical member with a substantially equal cross-section, and the center of the housing 16 is a cylindrical cavity 165 with both ends open. The lower part of the shell 16 cylinder wall (direction with figure 2 What is shown prevails, and the same below) is provided with an oil inlet 161 and two oil inlet passages 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com