Ultrasonic temperature-controlled reinforced mixer

An ultrasonic and mixer technology, applied in mixer accessories, mixers, shaking/oscillating/vibrating mixers, etc., can solve the problems of single function, low degree of automation control, and poor temperature control function of booster mixers, and achieve a high degree of automation. , Easy to operate, the effect of increasing the stirring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

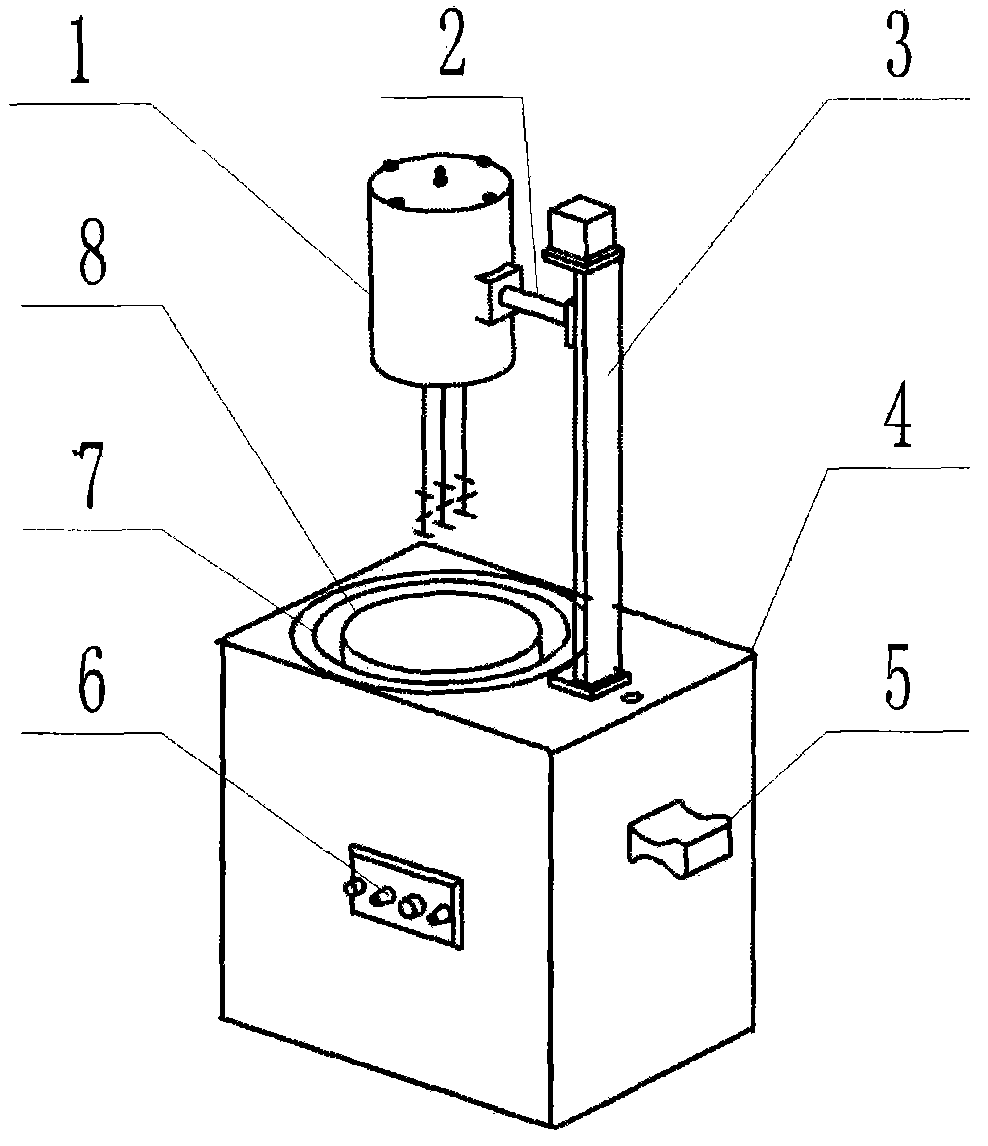

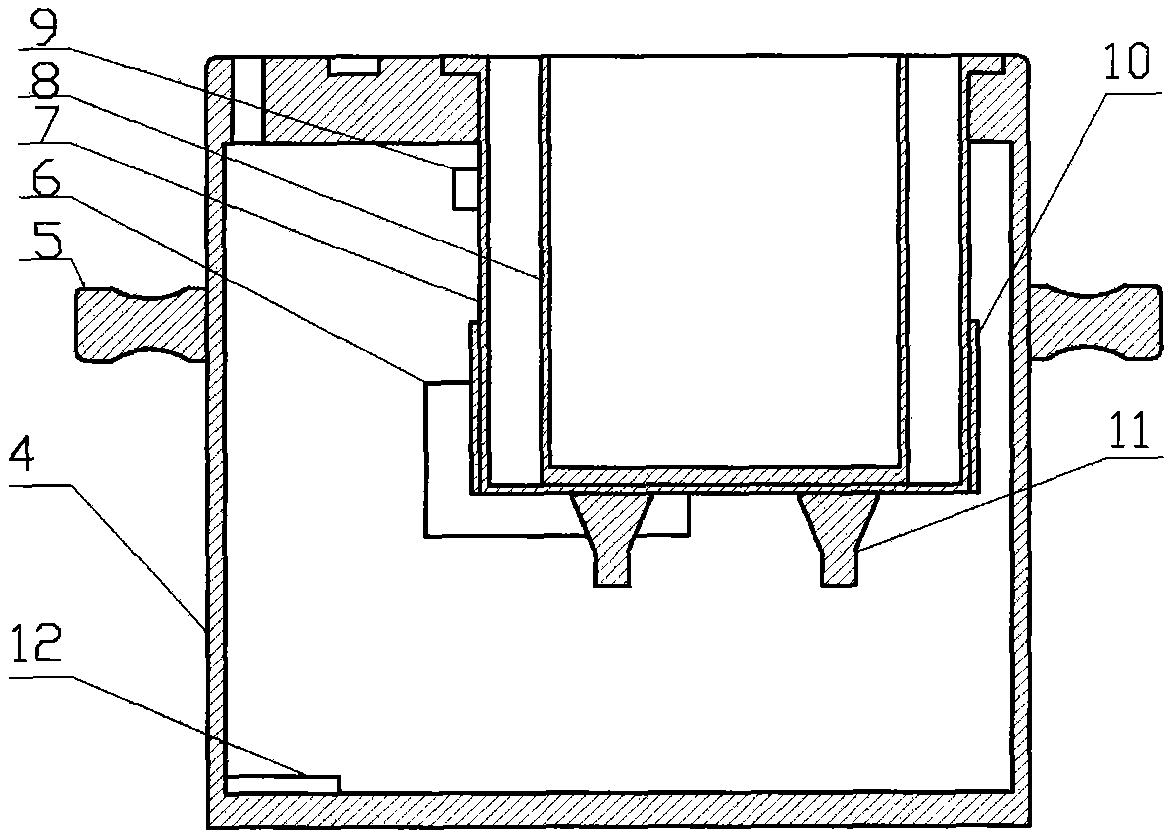

[0024] Such as figure 1 , 2 , 3, 4, and 5, the ultrasonic temperature-controlled booster mixer is mainly composed of a planetary gear stirring mechanism 1, a screw slide 3, a box body 4, an inner tank 7, a beaker 8, an annular heating ring 10, an ultrasonic vibrating head 11, etc. constitute.

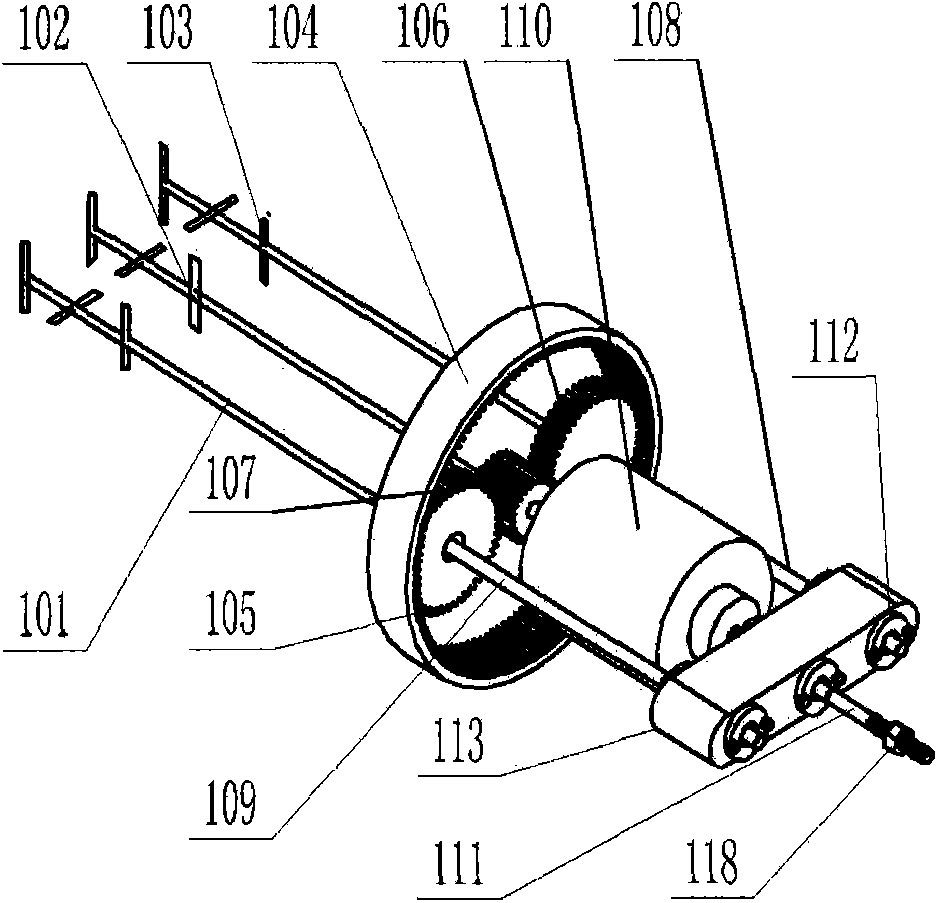

[0025] Such as image 3 , 4 The large internal meshing gear 104, the left planetary gear 105, the right planetary gear 106, and the central gear 107 form a planetary gear train. The internal meshing large gear 104 is lowered into the sleeve 109 by heating, and has an interference fit with the inner diameter of the sleeve 119, so that The ring gear 104 remains fixed and does not rotate during operation. The central gear 107 is connected with the output shaft of the driving motor through a flat key, and the upper end of the driving motor is connected with the fixed shaft 111 as a whole. The end is tapped with an external thread 118 at a specific distance, and the center of the top co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com