Unsaturated fatty alcohol polypropylene oxide-polyoxyethylene segmented copolymer as well as preparation method and application thereof

A technology of alcohol polyoxypropylene polyoxyethylene block and enol polyoxypropylene ether, which is applied in the field of surfactants for tertiary oil recovery, can solve problems such as unsatisfactory effects, achieve good fluidity and water solubility, and increase viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

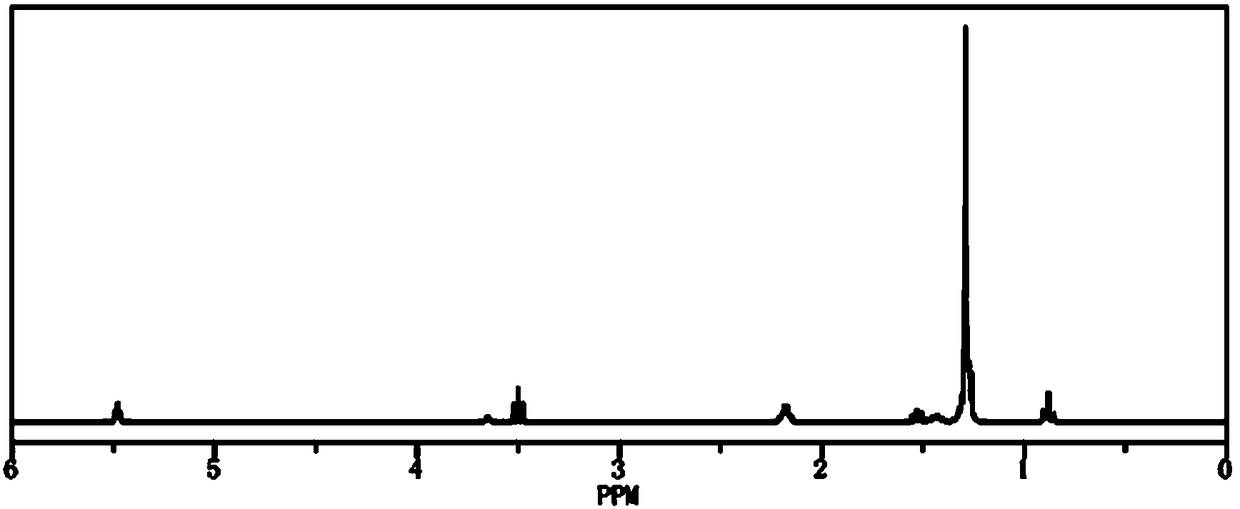

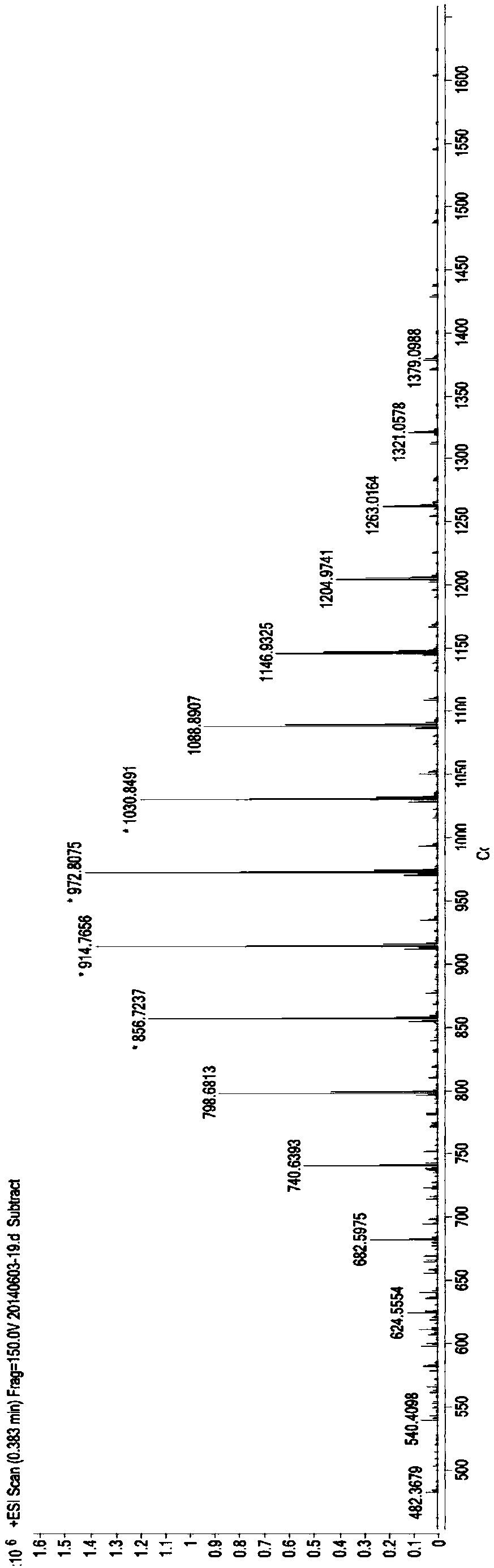

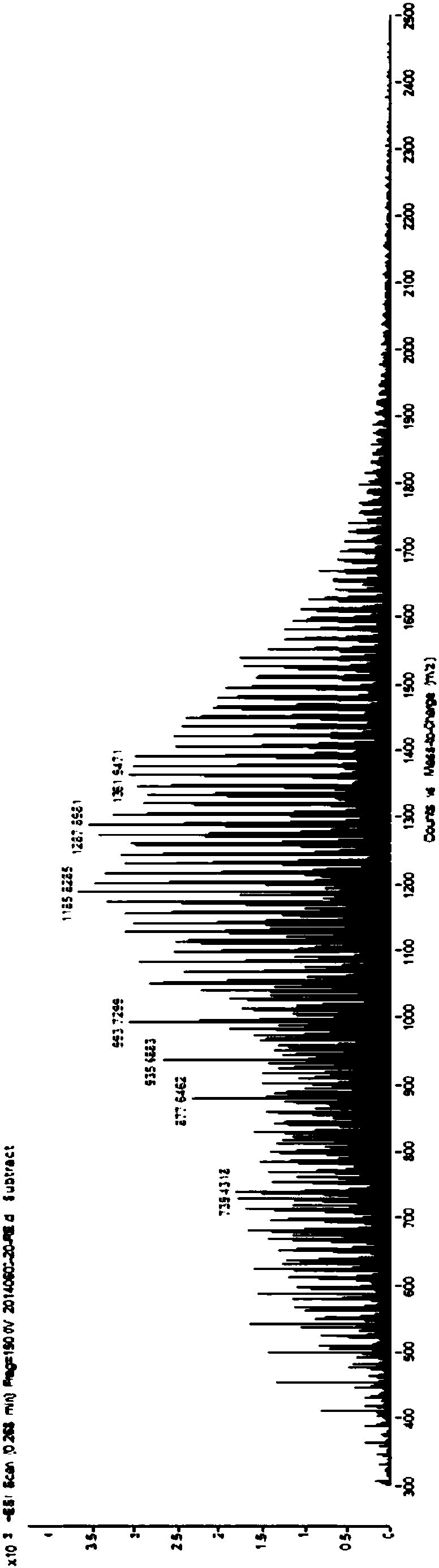

[0048] In this example, erucic acid C22 was used as a starting material to prepare a C22 fatty alcohol polyoxypropylene polyoxyethylene block copolymer containing unsaturated double bonds. The specific operation is as follows.

[0049] 1. Esterification reaction

[0050] (1) Reaction formula:

[0051] CH 3 (CH 2 ) 8 =(CH 2 ) 12 COOH+CH 3 CH 2 OH→CH 3 (CH 2 ) 8 =(CH 2 ) 12 COOCH 2 CH 3 +H 2 o

[0052] (2) Specifications of raw materials:

[0053] Industrial-grade high-purity erucic acid C22:1 content>95%, iodine value (gI 2 / 100g) 80-90, water content 99.0%, water content <0.1%

[0054] (3) Raw material ratio:

[0055] Erucic acid: ethanol = 1:5 (molar ratio)

[0056] (4) Synthesis process:

[0057] Add erucic acid and ethanol into the reaction kettle according to the molar ratio of 1:5 (molar ratio). After the temperature is raised to 90°C, the reaction starts. During the reaction, ethanol is gradually added (the ethanol is sufficiently excessive to make ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com