Wood salt-free dyeing method

A salt-free dyeing and wood technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of increasing the difficulty and cost of printing and dyeing wastewater treatment, deterioration of water quality and soil quality, degradation and recycling, etc., easy to achieve industrial implementation , lower surface tension, lower adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of salt-free staining method of wood of the present embodiment specifically comprises the following steps:

[0038] S1. Pretreatment: The poplar veneer sample (specification 100×50×2mm) is prepared at a bath ratio of 1:40, a concentration of NaOH of 0.2%, and a concentration of cetyltrimethylammonium bromide (CTAB) of 0.8 %, the extraction temperature is 8h in a water bath environment with an extraction temperature of 60°C, and then transferred to a bath ratio of 1:80, H 2 o 2 The concentration is 5%, and the leaching temperature is 60°C hydrogen peroxide solution for 4 hours, and the wood is dried at 40°C until the moisture content is 28%±1%.

[0039] S2, 20g reactive blue M-2GE is dissolved in 60% ethanol aqueous solution, mixes evenly, obtains 1% reactive blue M-2GE ethanol aqueous solution;

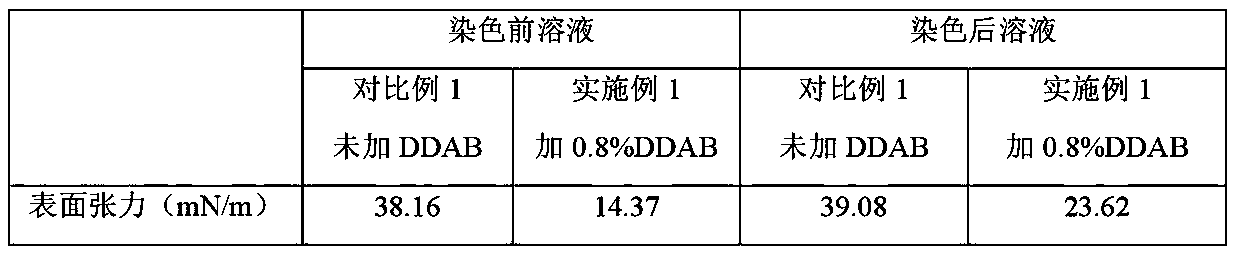

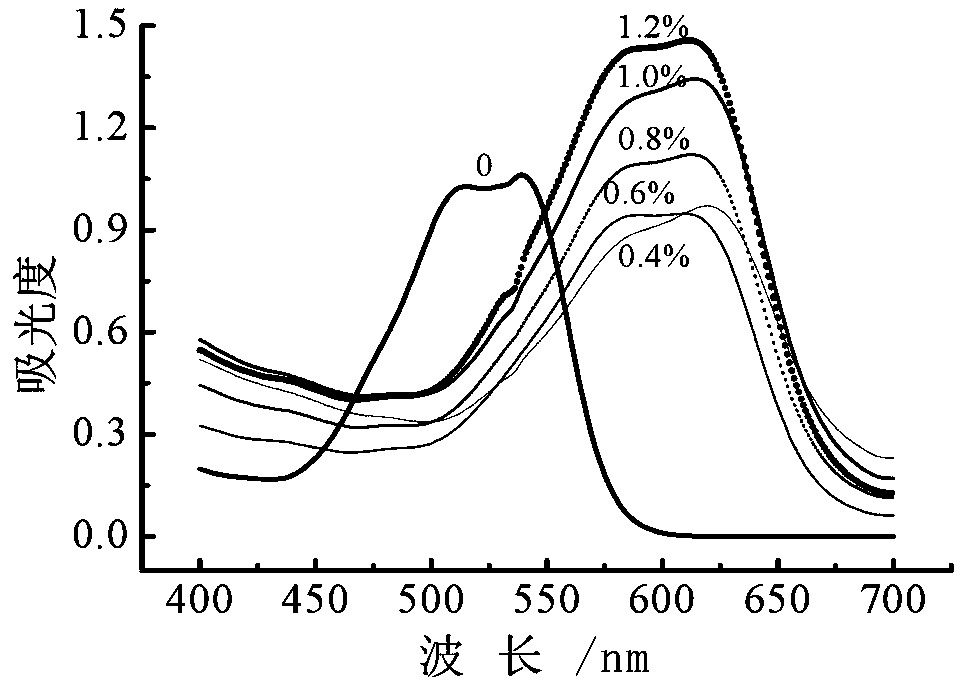

[0040] S3. Dyeing: Weigh the poplar after S1 and put it into a stainless steel dyeing vat with a cover, and then add reactive blue M-2GE ethanol aqueous solution and 0...

Embodiment 2

[0055] A kind of salt-free staining method of wood of the present embodiment specifically comprises the following steps:

[0056] S1. Pretreatment: The eucalyptus veneer sample (specification 100×50×2mm) is prepared at a liquor ratio of 1:30, a NaOH concentration of 0.2%, and a polyoxyethylene octylphenol ether-10 (OP-10) concentration of 1.0%, leached for 8 hours in a water bath environment with an leaching temperature of 80°C, and then transferred to a bath ratio of 1:60, H 2 o 2 The concentration is 6%, the leaching temperature is 80°C hydrogen peroxide solution for 4 hours, and the wood is dried at 40°C until the moisture content is 28%±1%.

[0057] S2, 20g active yellow M-3RS is dissolved in 80% ethanol aqueous solution, mixes evenly, obtains 1% active yellow M-3RS ethanol aqueous solution;

[0058] S3. Dyeing: Weigh the eucalyptus after S1 and put it into a stainless steel dyeing vat with a cover, then add reactive yellow M-3RS ethanol aqueous solution and 1.2% dimethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com