No-tillage seeder matching with micro-tiller

A micro-tiller and seeder technology, applied to the parts of the seeder, fertilizers, seeding equipment, planting methods, etc., can solve the problems of low production efficiency and operation quality, inaccurate separation of seed and fertilizer, and high labor intensity. Good quality, improved planting level, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

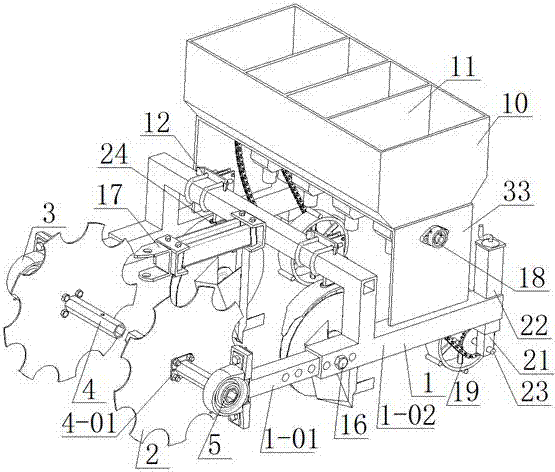

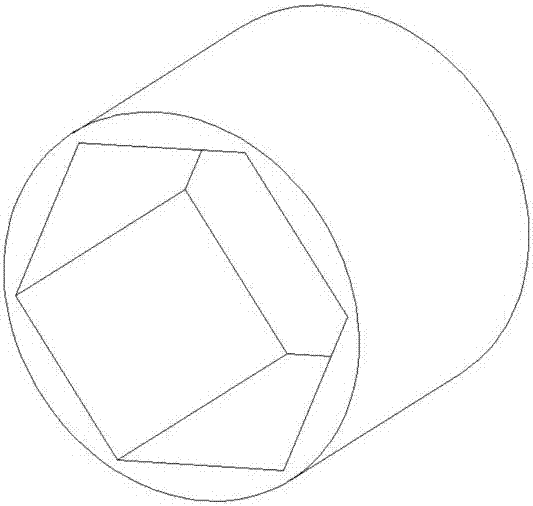

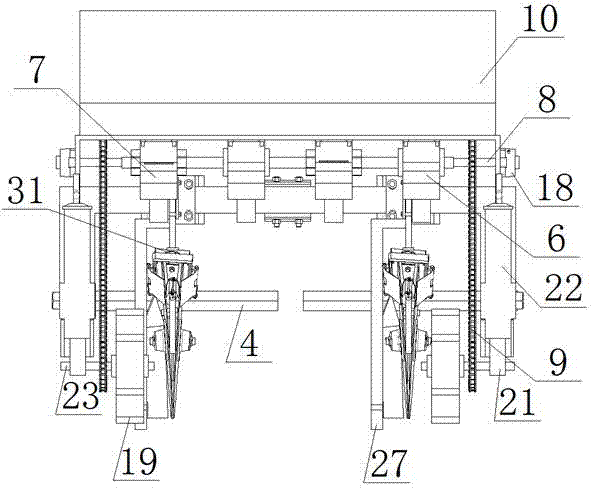

[0026] Embodiment 1: as Figure 1-10 As shown, a no-tillage seeder matched with a tiller includes a frame 1, a notched disc 2, a bearing seat I3, a hexagonal tube 4, a shaft sleeve 5, a seed meter 6, a fertilizer discharge device 7, a seed meter Fertilizer discharge drive mechanism 8, seed discharge and fertilizer transmission mechanism 9, seed fertilizer box 10, U-shaped pipe clamp 12, sprocket Ⅰ13, seed discharge and fertilizer fixing bolt 14, seed discharge and fertilizer connecting plate 15, bolt 16, hook bracket 17. Bearing seat II 18, ground wheel 19, rocker 20, lifting pipe 21, connecting hollow pipe 22, connecting shaft 23, double disc ditching seeding and fertilizing mechanism 24, sprocket II 32 and support frame 33, the double disc Ditching, sowing and fertilizing mechanism 24 comprises disc 25, shovel handle 26, fertilizer discharge pipe 27, guard plate 28, baffle plate 29, soil scraper 30, seeding pipe nozzle 31, cutterhead shaft 34, seeding plate 35 and Fixing se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com