Automobile jack and lifting method thereof

A technology for jacks and cars, applied in the direction of lifting devices, etc., can solve problems such as difficulty in arranging jacks, inconsistent maximum lifting heights, safety issues, etc., and achieve the effect of saving layout space, broad market prospects, and smaller storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical content of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the solution of the present invention more clearly, but this does not limit the protection scope of the present invention.

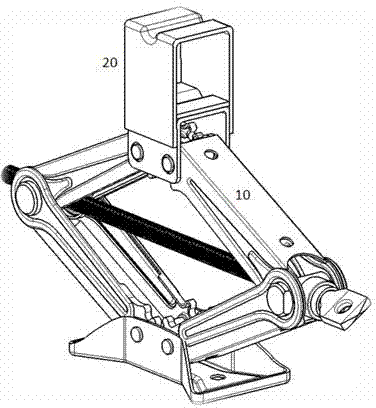

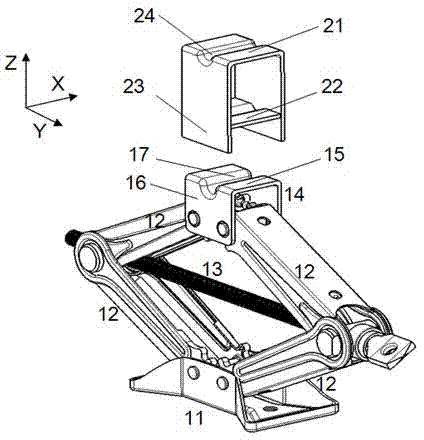

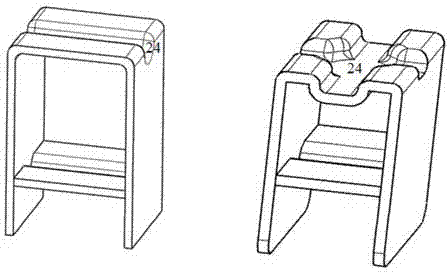

[0030] as attached figure 1 with 2 As shown, the automobile jack of the present invention as a whole includes a jack body 10 and a detachable plug 20 . The jack body 10 has a scissor structure, and includes a base 11, a lifting arm 12, a screw 13 and a fixed head 14. The lifting arm 12 has four sections, which are hingedly connected to each other to form a diamond-shaped scissor structure. The bottom end of 12 is hinged to base 11, and the top of lift arm 12 is connected to fixed head 14, and the middle part of lift arm 12 is connected to leading screw 13 by rotatable screw thread at every two sections of hinges along the rhombus diagonal line, so that by turning Turning t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com