Machineshop truck driver's cab with reinforced turnover protection device

A protection device and driver's cab technology, applied to the upper structure of the truck, vehicle parts, transportation and packaging, etc., can solve the problems of poor safety protection performance, achieve simple structure, convenient implementation and use, and improve the degree of generalization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

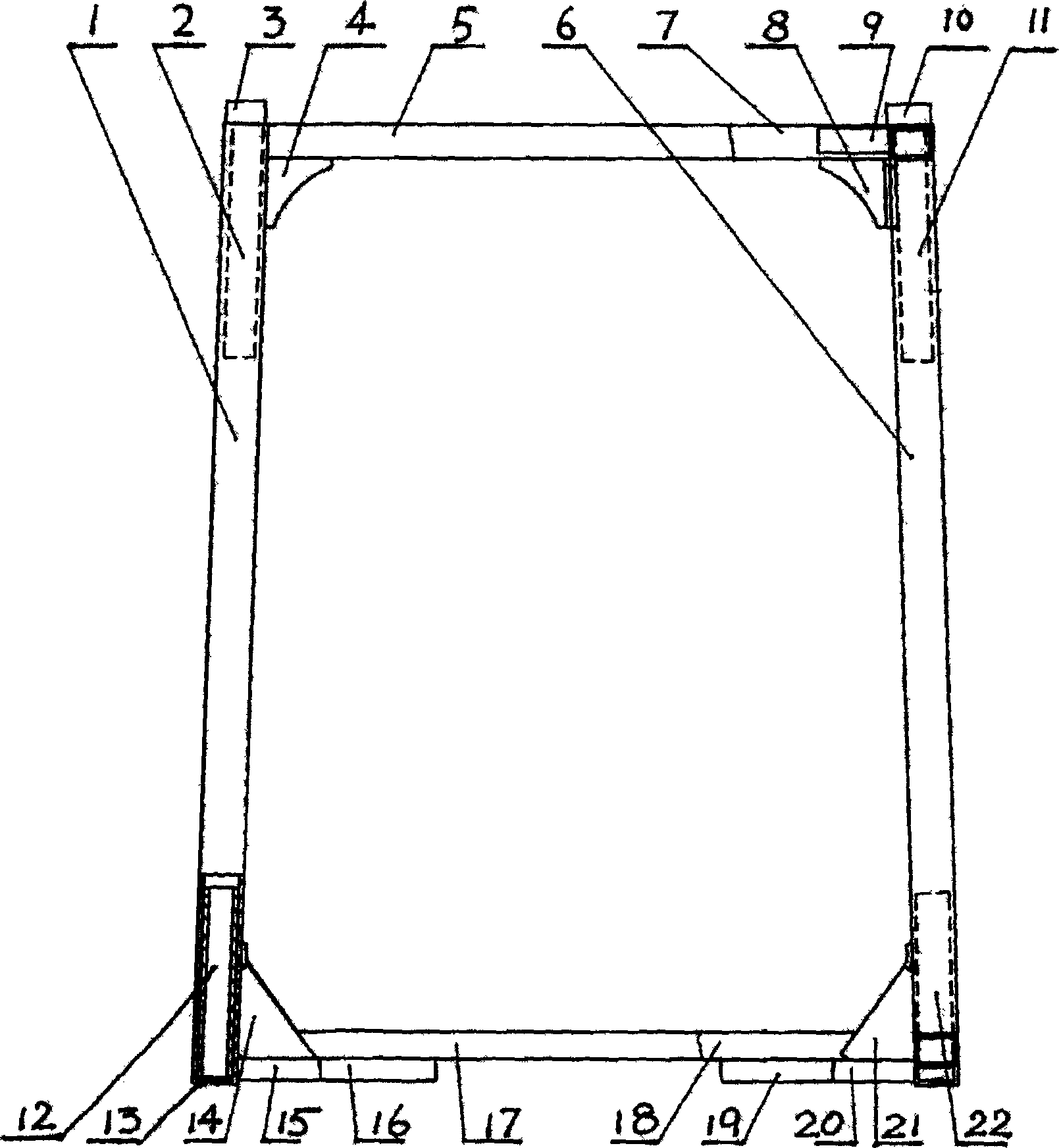

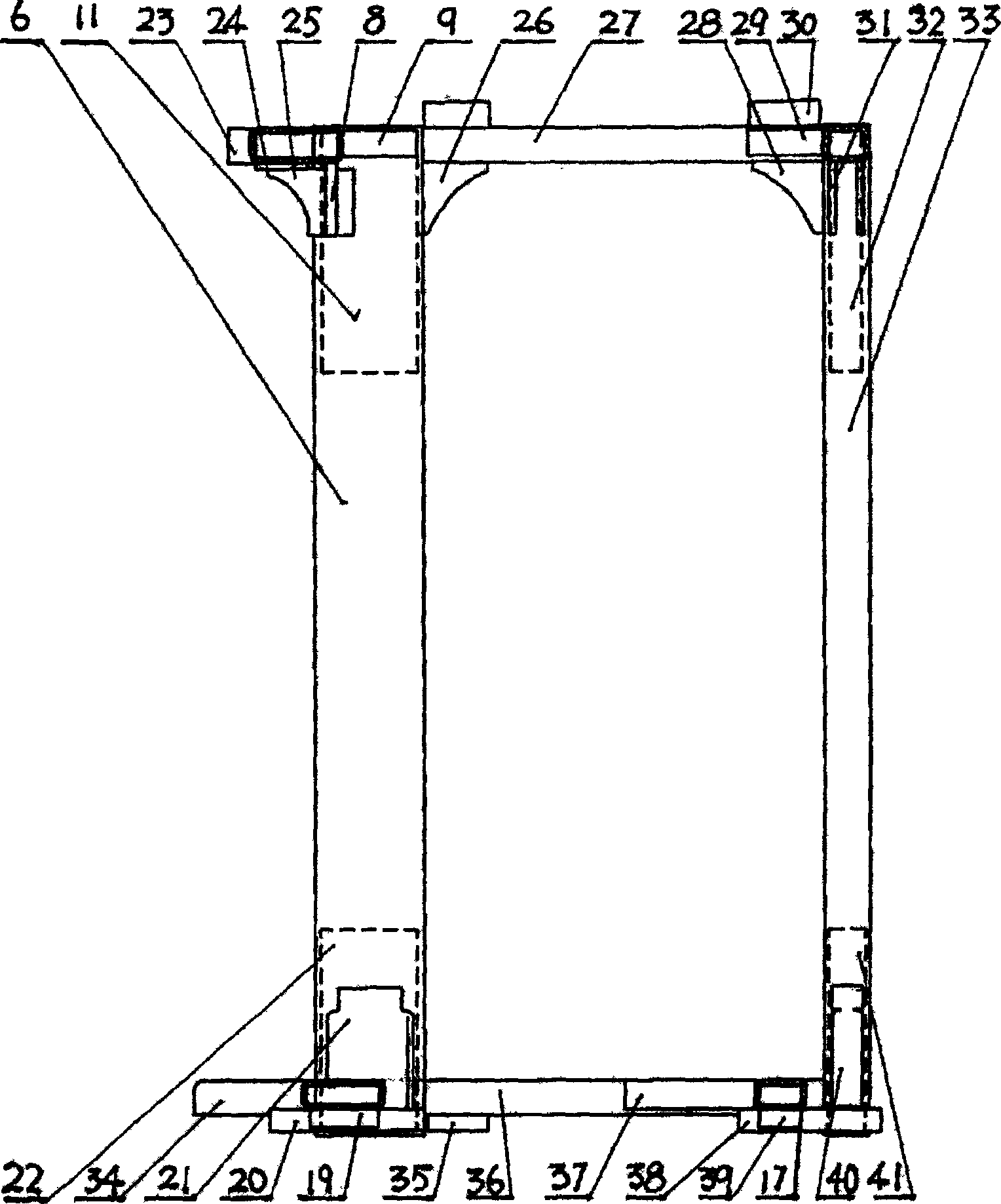

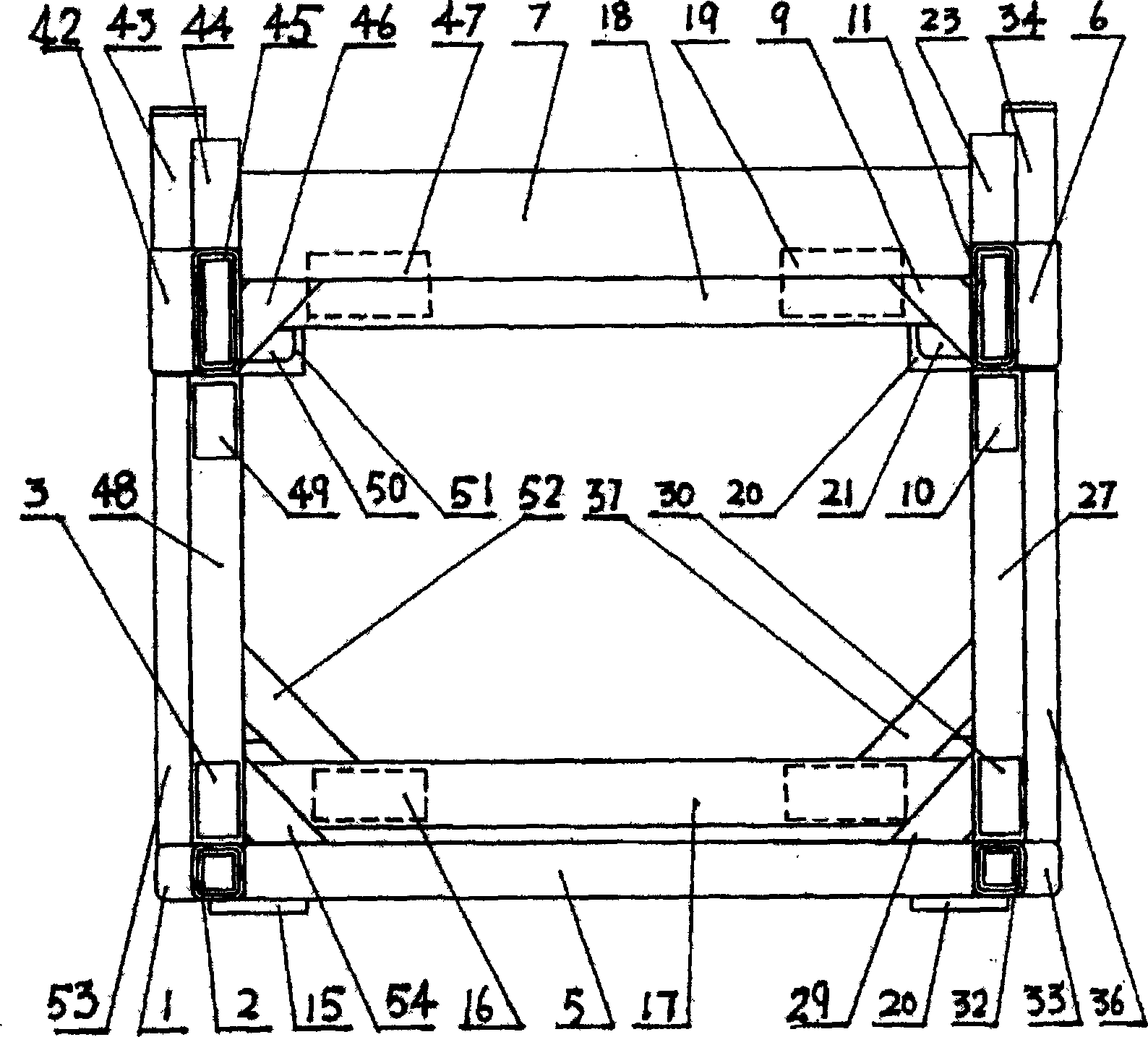

[0022] The present embodiment is to adopt the best protective structure as an example, that is, by the right front column 1, the left front column 33, the front lower beam 17, the front upper beam 5, the left rear column 6, the left upper beam 27, the left lower beam 36, the right rear column 42 , upper right crossbeam 48, right lower crossbeam 53, rear upper crossbeam 7, rear lower crossbeam 18 in the driver's cab frame:

[0023] The upper part of the right front column 1 has the upper end fixedly connected with the cab frame joint and the right front column upper composite beam 2 which is socketed downward with the right front column 1; 1 the composite beam 12 under the right front column that is socketed; the composite beam 2 on the right front column and the composite beam 12 under the right front column are socketed in the right front column 1

[0024] The upper part of the left front column 33 has the upper end fixedly connected with the cab frame joint and the left fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com