Anti-slip rubber composite for sole and preparation method of anti-slip rubber composite

A composite material, anti-skid rubber technology, applied in the field of rubber materials, can solve the problems of poor anti-skid performance of soles, easy to accumulate water and ice on the road, easy to slip and fall, etc., to improve product quality, significant economic benefits, and wear resistance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

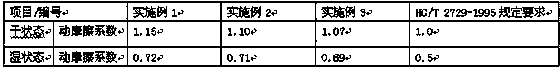

Examples

Embodiment 1

[0022] An anti-slip rubber composite material for shoe soles, prepared from the following raw materials in parts by weight: 100 parts of natural rubber, 45 parts of carbon black, 5 parts of zinc oxide, 2 parts of stearic acid, N-isopropyl-N'-benzene 1 part of p-phenylenediamine, 1 part of 2,4-trimethyl-1,2-dihydroquinoline polymer, 2 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 2 parts of diphenylguanidine 2 parts, sulfur 2 parts.

[0023] The preparation steps are as follows:

[0024] The natural rubber is masticated on the two-roll mill to cover the rolls, and then zinc oxide, stearic acid, N-isopropyl-N'-phenyl-p-phenylenediamine, 2,4-trimethyl-1 , 2-dihydroquinoline polymer, -cyclohexyl-2-benzothiazole sulfenamide, diphenylguanidine, carbon black, and finally add sulfur in order, and mix evenly to obtain a rubber compound. After the mixed rubber is parked for 15-20 hours, the mixed rubber prepared in step (1) is vulcanized with a vulcanizer for 10-20 minutes, and t...

Embodiment 2

[0026] An anti-slip rubber composite material for shoe soles, prepared from the following raw materials in parts by weight: 100 parts of natural rubber, 44 parts of carbon black, 4 parts of zinc oxide, 1 part of stearic acid, N-isopropyl-N'-benzene 1 part of p-phenylenediamine, 1 part of 2,4-trimethyl-1,2-dihydroquinoline polymer, 1 part of N-cyclohexyl-2-benzothiazole sulfenamide, 1 part of diphenylguanidine 1 part, sulfur 1 part.

[0027] According to the same method as in Example 1, the anti-skid rubber composite material for shoe soles was prepared.

Embodiment 3

[0029] An anti-slip rubber composite material for shoe soles, prepared from the following raw materials in parts by weight: 100 parts of natural rubber, 46 parts of carbon black, 6 parts of zinc oxide, 3 parts of stearic acid, N-isopropyl-N'-benzene 1 part of p-phenylenediamine, 1 part of 2,4-trimethyl-1,2-dihydroquinoline polymer, 3 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 3 parts of diphenylguanidine 3 parts, sulfur 3 parts.

[0030] According to the same method as in Example 1, the anti-skid rubber composite material for shoe soles was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com