Nano vaporization fogging device

A fog-making device and nano-technology, which is applied in the field of mechanical equipment and electrical equipment, can solve the problems of high liquid mist temperature, low fog-making efficiency, and high manufacturing cost, and achieve high fog-making efficiency, moderately adjustable liquid mist temperature, and manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

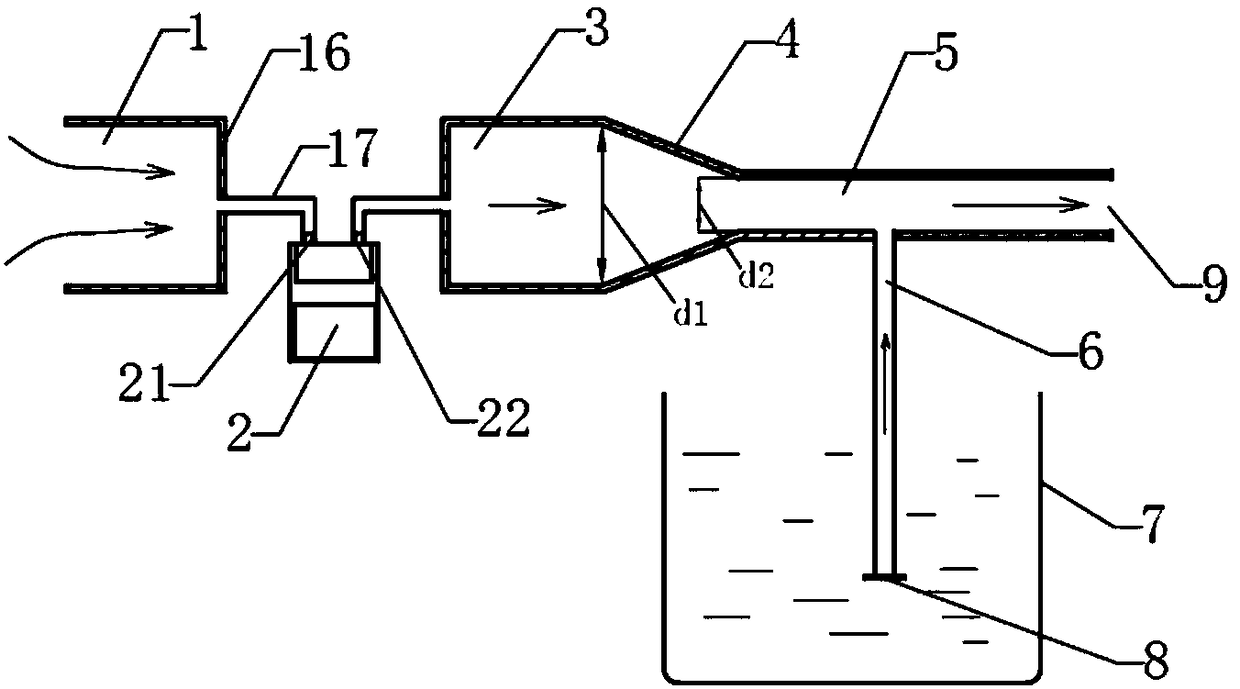

[0029] Such as figure 1 As shown, the nano-vaporization fog-making device includes: gas inlet pipe 1, gas pump 2, gas outlet pipe 3, reducer pipe 4, throat pipe 5, vaporization pipe 6, liquid tank 7, injection port 9, the liquid tank The opening of 7 is an open state, and the liquid tank 7 communicates with atmospheric pressure.

[0030] The gas pump 2 is used to pressurize the gas. The suction port 21 and the delivery port 22 of the gas pump 2 are sequentially connected to the gas inlet pipe 1 and the gas outlet pipe 3 .

[0031] The gas inlet pipe 1 and the gas outlet pipe 3 are provided with a cover 16 at the connecting end of the gas pump 2, and the center of the cover 16 is connected with a gas thin tube 17, and the two ends of the gas thin tube 17 are connected with the corresponding gas pump respectively. The suction port 21 and the delivery port 22 of 2 are connected.

[0032] The reducer 4 and the throat 5 form a jet tube, and the inner diameter of the reducer 4 is ...

Embodiment 2

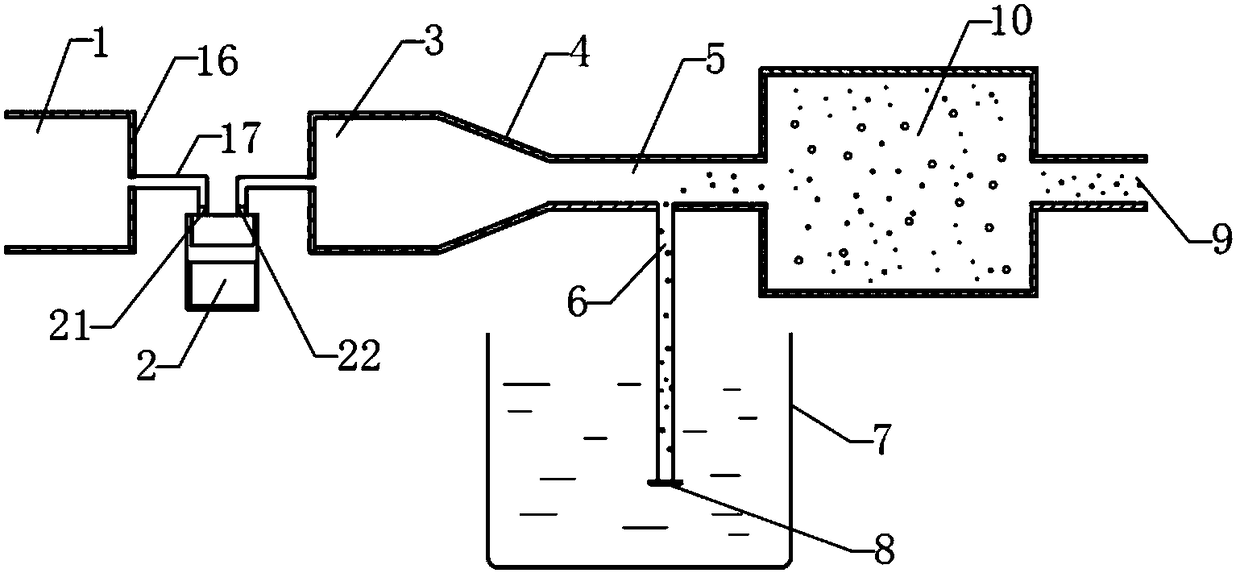

[0048] Such as figure 2 As shown, a buffer chamber 10 is provided at the injection port 9, so that the gas, steam and liquid particles can be mixed more fully.

[0049] Other structures are the same as in Embodiment 1.

Embodiment 3

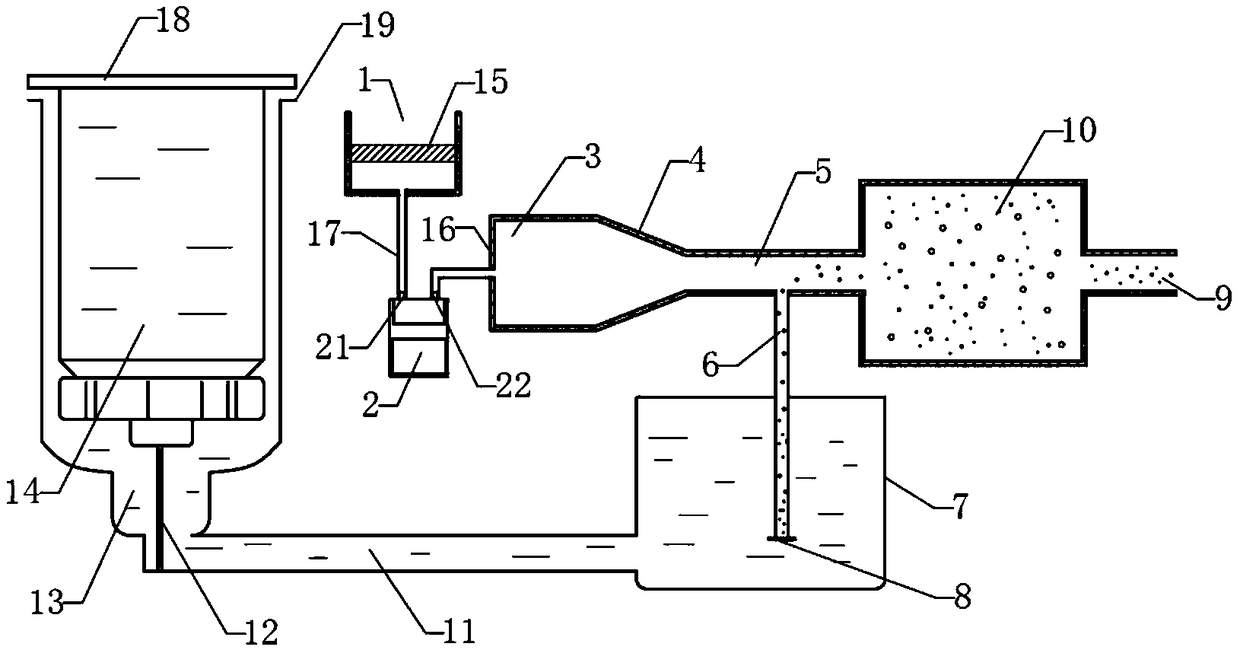

[0051] Such as image 3 As shown, the top of the liquid tank 7 is closed, and the liquid tank 7 is provided with an automatic liquid replenishment device. The automatic liquid replenishment device includes a liquid replenishment tank 14, a liquid replenishment tank 13 and a liquid replenishment rod 12. The liquid replenishment tank 13 is connected to the liquid tank through a connecting pipe 11. 7 is connected, and the liquid replenishment tank 13 is vertically provided with a liquid replenishment rod 12. When the liquid replenishment tank 14 filled with liquid is placed in the liquid replenishment tank 13, the automatic locking device in the cover of the liquid replenishment tank 14 is pushed open by the liquid replenishment rod 12, and the liquid replenishment tank The liquid in 14 flows into the liquid replenishing tank 13, and automatically replenishes liquid in the liquid tank 7 through the connecting pipe 11.

[0052] The top of the liquid replenishment tank 14 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com