Filter press filter plate embedded filter cloth filter plate sealing rope ring and manufacturing method

A production method and technology of sealing rope, which are applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of large environmental pollution, slow disassembly, and difficult to recycle, and achieve no environmental pollution, low manufacturing cost, and sealing and fixing. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

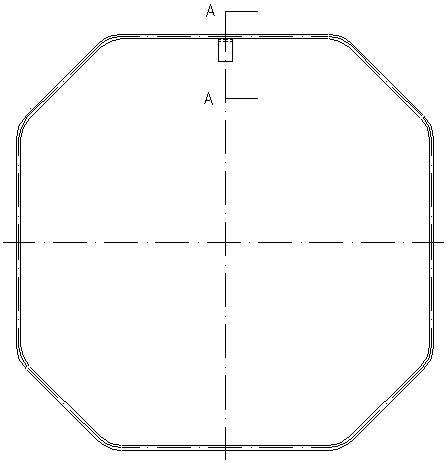

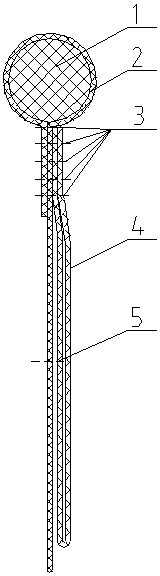

[0012] Embodiment 1: with reference to attached figure 1 and 2 . A filter plate of a filter press is embedded with a filter cloth filter plate sealing rope, which is characterized in that: the filter cloth 2 is inserted into the sealing groove in the filter plate through the sealing cotton rope 1 and the filter cloth 2 is fixed and sealed.

Embodiment 2

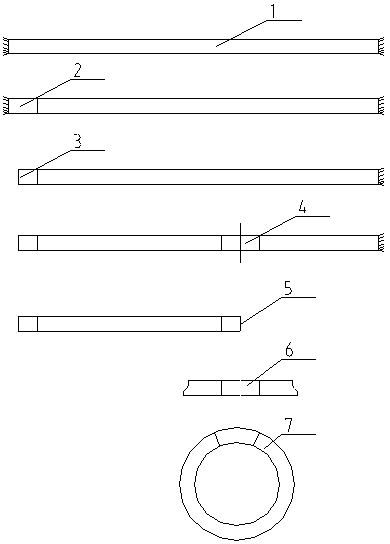

[0013] Embodiment 2: with reference to attached image 3 . On the basis of embodiment 1, a kind of manufacture method of filter cloth filter plate seal rope ring, a. select the long cotton rope 1 of suitable diameter, color, hardness and weaving method for use, generally present burrs at two ends; b. Wrap 2~3 layers of film material 2 at one end, with appropriate tightness, and then use a special cutting tool to cut off excess wool to form a neat cotton rope end 3; c. Make a mark on the required length, and wrap 2~3 layers of film material here as well 4. The tightness is qualified, and then use a special cutting tool to cut off the excess wool at the marked place to form a neat cotton rope end 5; d. Get the cotton rope section, align the two ends tightly, and wrap or wrap the two ends with the film material 6 The film material 6 can be heat-shrinkable material or hot-melt adhesive, so that the loop-shaped cotton rope 7 can be formed through heat-shrinking or gluing treatment...

Embodiment 3

[0014] Embodiment 3: On the basis of Examples 1 and 2, a method for matching the sealing rope and filter cloth, using cotton rope to sew the embedded filter cloth cover or piece, the joint of cotton rope should be sewn first, And it should be sewn on the straight side of the filter cloth, and the other sewing methods are the same as the embedded filter cloth fixed by ordinary O-rings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com