Manufacturing method for composite hammer head of hammer crusher

The technology of hammer crusher and compound hammer head is applied in the field of preparation of compound hammer head of hammer crusher, which can solve the problems of limited improvement in wear resistance, fast cooling speed, and large WC ratio, and achieve high wear resistance and High strength and toughness, simple production process and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

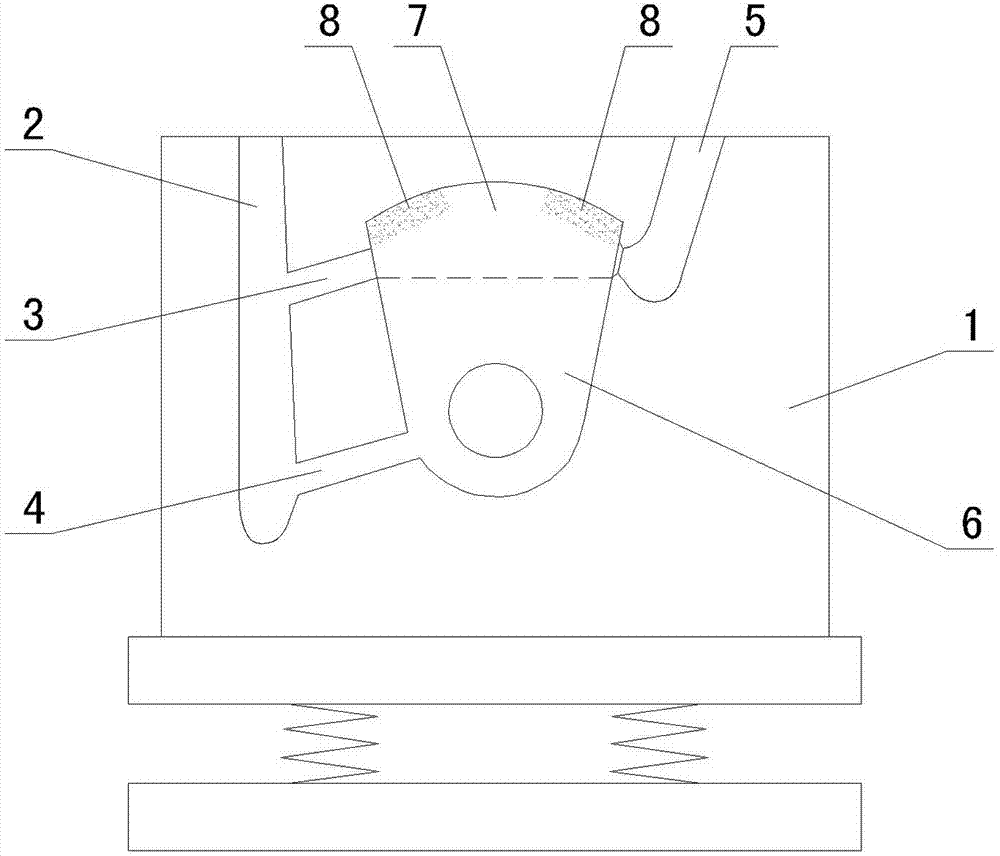

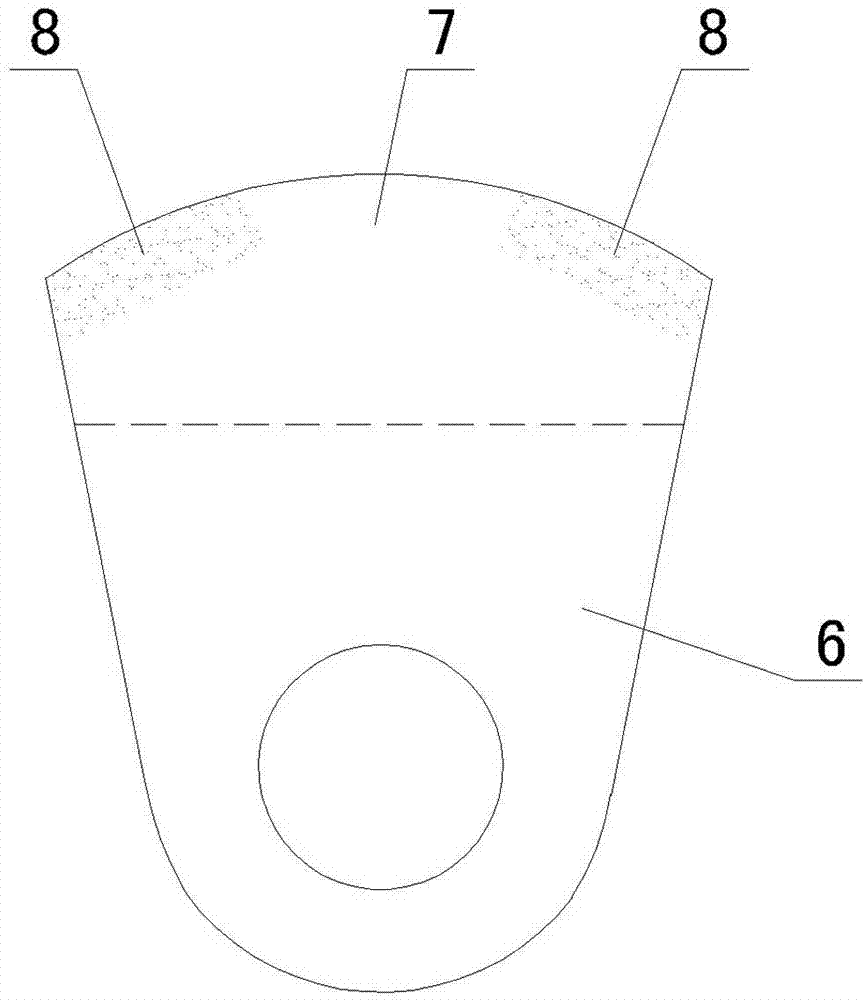

[0032] 1) The preparation of composite hammer mold 1 is to use 20-140 mesh quartz sand with a mud content of 2 Hardening, brushing zircon powder quick-drying paint on the cavity surface of the mold; and the mold is provided with a sprue 2 and two inrunners, and the inrunner 4 at the bottom is used for pouring low-carbon low-alloy steel 6, the inner runner 3 on the upper layer is used for pouring high-chromium cast iron 7, and the mold is also provided with an observation hole 5, which doubles as a compound hammer head riser;

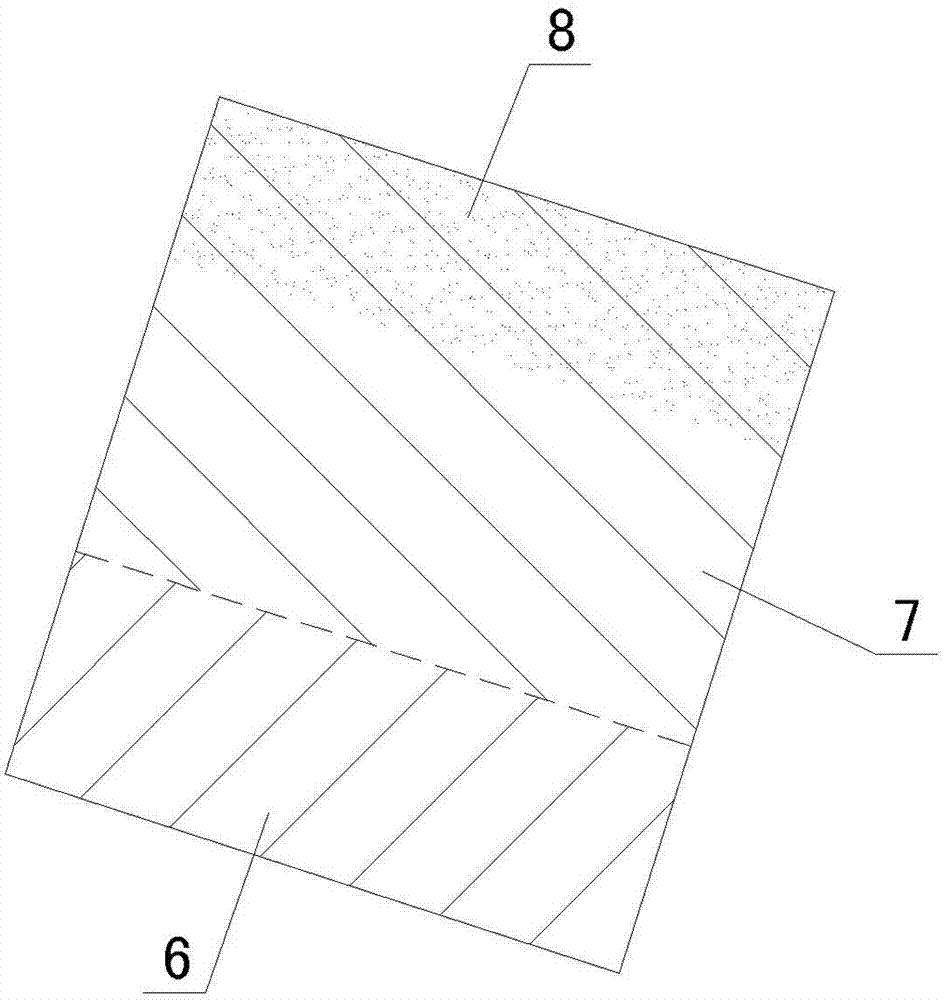

[0033] 2) Add Al 2 o 3 Ceramic particles or ZrO 2 The ceramic particles or ZTA ceramic particles are mixed with the binder evenly and placed in the shaping mold, and solidified to obtain a strip-shaped or plate-shaped preform 8 with three-dimensional interconnection and multi-dimensionality, and the ability to resist high-temperature liquid metal erosion without collapsing;

[0034] 3) Fix the prefabricated body 8 in the cavity of the above-mentioned c...

Embodiment 1

[0039] High chromium cast iron adopts Cr15 type, the composition is (weight percentage) C: 3.6%, Cr: 15%, Mo: 0.5%, Ni: 0.5%, Si: 0.6%, Mn: 0.6%, S≤0.04%, P≤ 0.04%, the rest is Fe;

[0040] Low-carbon low-alloy steel composition (weight percentage) C: 0.28%, Cr: 1%, Si: 0.6%, Mn: 0.6%, P≤0.04%, S≤0.04%, Al: 0.025%, and the rest is Fe;

[0041]The ceramic particles are made of Al 2 o 3 Ceramic particles, the Al 2 o 3 Ceramic particles are mixed with 3% binder and placed in a shaped mold, solidified to obtain Al 2 o 3 Ceramic particle preform;

[0042] The composite hammer head mold is made of 20-140 mesh quartz sand, with a mud content of <0.2%, added with 5% water glass, and hardened by CO2, and the cavity surface of the mold is painted with zircon sand quick-drying paint;

[0043] The box is fixed on a mechanical vibration device, and two intermediate frequency furnaces are used to melt Cr15 high-chromium cast iron liquid and low-carbon low-alloy steel liquid respectiv...

Embodiment 2

[0047] The difference between this embodiment and embodiment 1 is:

[0048] High chromium cast iron adopts Cr20 type, the composition is (weight percentage) C: 3.2%, Cr: 20%, Mo: 0.5%, Ni: 0.5%, Si: 0.6%, Mn: 0.6%, P≤0.04%, S≤ 0.04%, the rest is Fe;

[0049] Low-carbon low-alloy steel composition (weight percent) C: 0.3%, Cr: 1%, Mn: 0.6%, Si: 0.6%, P≤0.04%, S≤0.04%, Al: 0.025%, and the rest is Fe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com