Serial connection type power dividing ball joint

A tandem and ball technology, which is applied in the direction of manufacturing tools, manipulators, belts/chains/gears, etc., can solve the problems of poor repeat positioning accuracy, high price, and large volume of RV reducers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

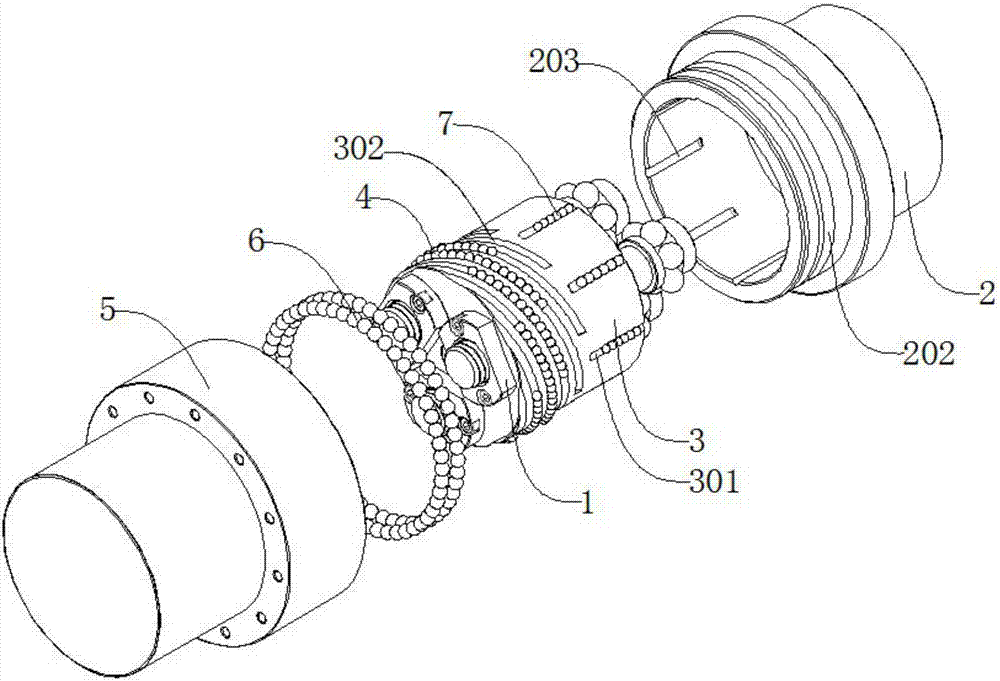

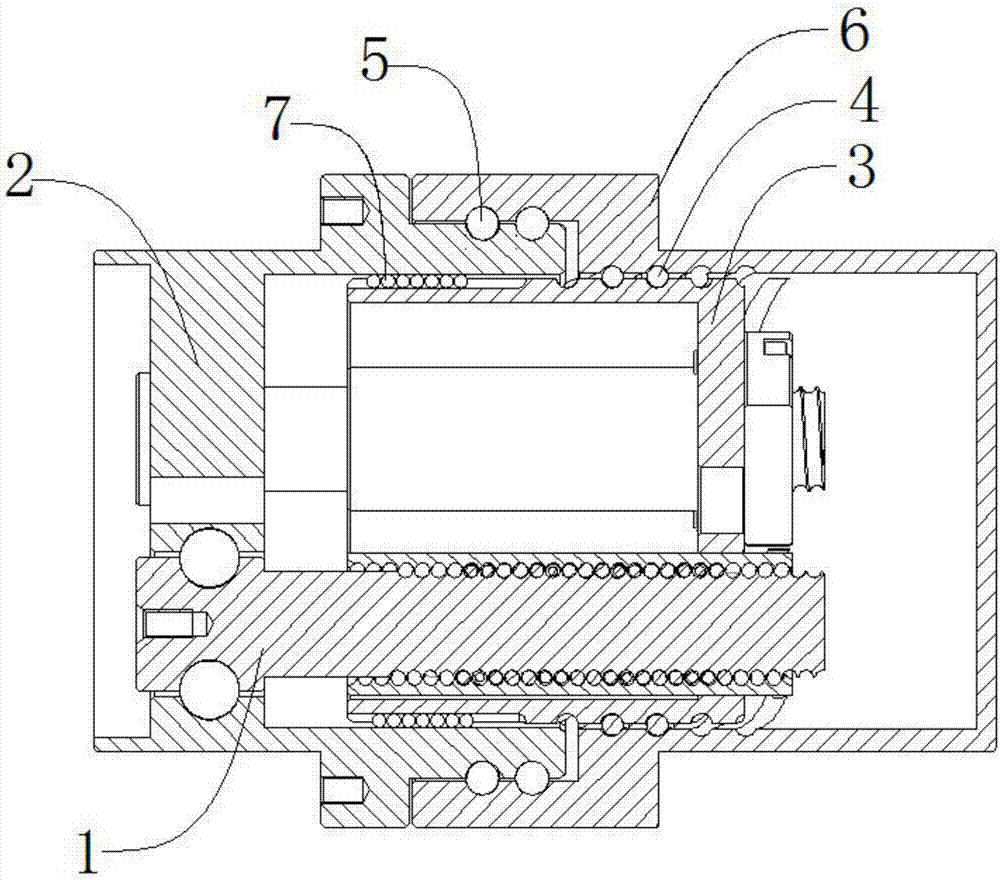

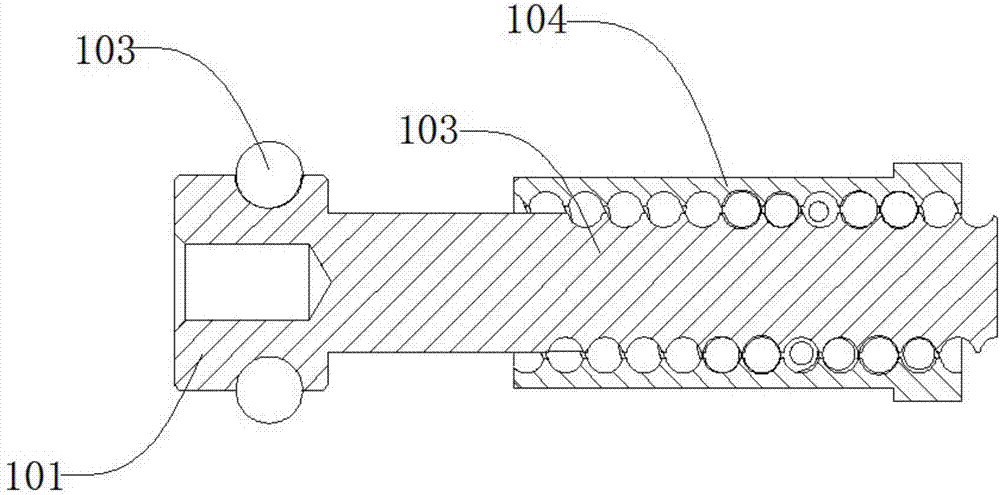

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6As shown, a tandem power splitting ball joint includes not less than two pieces of high-speed screw mechanism 1, static ring 2, low-speed nut sleeve 3, low-speed ball 4, moving coil 5, first supporting ball 6, guide Ball 7, the static ring 2 is located outside the high-speed screw mechanism 1, the static ring 2 is rollingly connected with the high-speed screw mechanism 1, and the low-speed nut sleeve 3 is penetrated by the high-speed screw mechanism 1 and located on the static ring 2, the low-speed nut sleeve 3 is threadedly connected with the high-speed screw mechanism 1 and is movably connected with the static ring 2, the low-speed ball 4 is located outside the low-speed nut sleeve 3, and the low-speed ball 4 is connected to the low-speed nut sleeve 3 rolling connection, the moving ring 5 is located outside the low-speed ball 4 and outside the static ring 2, the moving ring 5 is rollingly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com