Method for supplementing lithium powder to lithium-ion battery negative plate

A technology for lithium-ion batteries and negative plates, which is applied in battery electrodes, electrode manufacturing, circuits, etc., can solve the problems of inaccurate quantitative lithium intercalation, harsh environmental requirements, and high production costs, and achieve low cost, improved cycle, and narrowed restrictions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

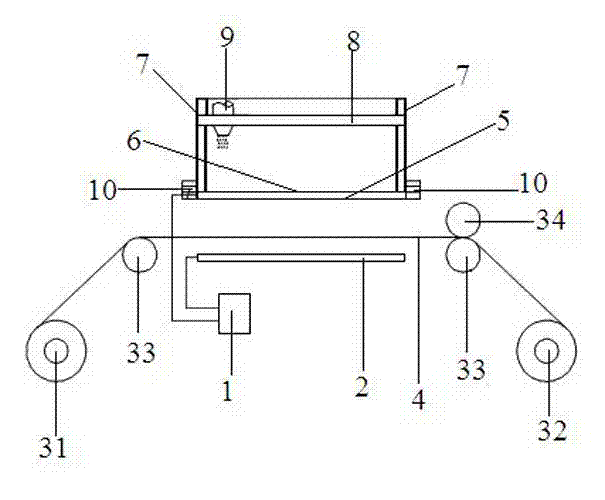

[0025] Such as figure 1 As shown, the device used in the method for replenishing lithium powder to the lithium ion battery negative electrode sheet of the present invention includes a rewinding and unwinding mechanism for placing and pulling the negative electrode sheet 4, a feeding mechanism 9 for placing lithium powder, and a device for providing an electric field. The high-voltage DC power supply 1 and the feeding mechanism 9 are located above the negative electrode sheet. Wherein, the winding and unwinding mechanism includes an unwinding roller 31, a winding roller 32, and two guide rollers 33 between the unwinding roller 31 and the winding roller 32, wherein, the positive side of a guiding roller 33 close to the winding roller 32 A pressing roller 34 is arranged above.

[0026] The method for supplementing the lithium-ion battery negative electrode sheet with the above-mentioned device includes the following steps: in the first step, the cold-pressed negative electrode s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com