Preparation method of slump loss resistant naphthalene water reducer

A naphthalene-based water reducer and slump-preserving technology, which is applied in the field of preparation of slump-retaining naphthalene-based water reducers, can solve problems such as environmental pollution, obvious seasonal fluctuations in industrial naphthalene price fluctuations, and impacts, and achieve reductions in environmental pollution, The effect of enhancing the controllability of the molecular structure and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

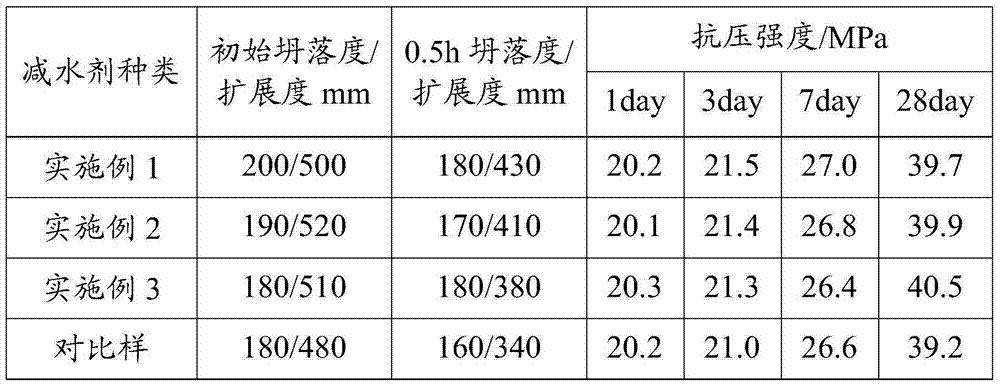

Examples

Embodiment 1

[0019] (1) Sulfonation: Add 100kg of industrial naphthalene and 20kg of methylnaphthalene to a closed reaction kettle A connected with a cooling reflux device, and start adding 110kg of concentrated sulfuric acid and 50kg of cyclohexane dropwise when the temperature rises to 120-130°C , the dropwise addition was completed within 0.5 hours. When the concentrated sulfuric acid is added dropwise, the temperature in the kettle is controlled at 160-170° C., and the heat preservation is continued for 1.5 hours. During the reaction process, the steam pipeline is connected to the lower part of the sulfonation reactor A, and the steam is introduced for 0.5 to 1 hour. The cyclohexane enters the cooling reflux device on the upper part of the reactor A along with the naphthalene steam for heat exchange and condensation, and the naphthalene steam and cyclohexane pass through After condensation, the cooling liquid is continuously sent to the reactor to continue the circular reaction until t...

Embodiment 2

[0024] (1) Sulfonation: Add 130kg of industrial naphthalene and 40kg of acenaphthene to the closed reaction kettle A connected with a cooling reflux device, and when the temperature rises to 130°C, start to add 150kg of concentrated sulfuric acid and 60kg of acetic acid dropwise, within 0.5 hours Finished adding. When the concentrated sulfuric acid is added dropwise, the temperature in the kettle is controlled at 155-165° C., and the heat preservation is continued for 2 hours. During the reaction process, the steam pipeline is connected to the lower part of the sulfonation reactor A, and the steam is introduced for 0.5 to 1 hour. The acetic acid enters the cooling reflux device at the upper part of the reactor A along with the naphthalene steam for heat exchange and condensation, and the naphthalene steam and acetic acid are condensed to form a cooling The liquid is continuously sent into the reactor to continue the circular reaction until the end of the reaction, and finally ...

Embodiment 3

[0029] (1) Sulfonation: Add 120kg of industrial naphthalene and 25kg of anthracene to the closed reaction kettle A connected to the cooling reflux device, and when the temperature rises to 125°C, start to add 150kg of concentrated sulfuric acid and 70kg of dichloromethane dropwise respectively, and in 1 hour The dropwise addition is completed. When the concentrated sulfuric acid is added dropwise, the temperature in the kettle is controlled at 160-170° C., and the heat preservation is continued for 2 hours. During the reaction process, the lower part of the sulfonation reactor A is connected to the steam pipeline, and the steam time is 0.5 to 1 hour. The dichloromethane enters the cooling reflux device on the upper part of the reactor A along with the naphthalene steam for heat exchange and condensation. The naphthalene steam and the dichloromethane pass through After condensation, the cooling liquid is continuously sent to the reactor to continue the circular reaction until t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com