A deep processing technology for coking washing oil

A deep processing and oil washing technology, which is applied in the chemical industry and can solve the problems of large investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

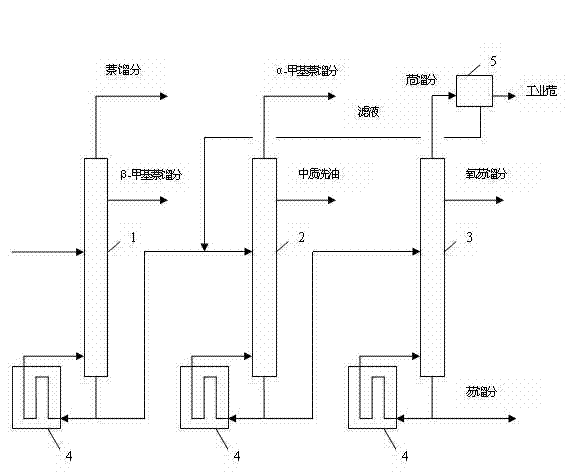

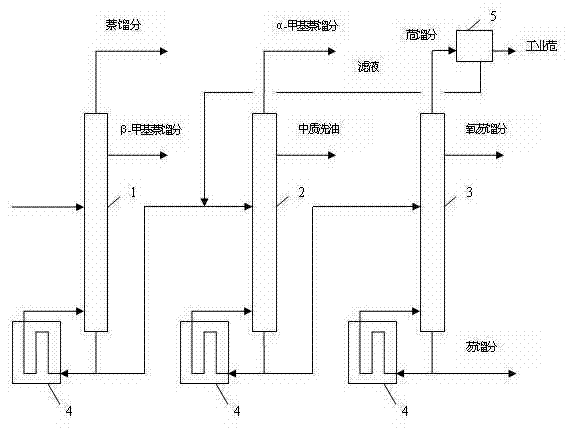

Image

Examples

Embodiment 1

[0027] Example 1 The washing oil treatment capacity is 10,000 tons / year

[0028] There are three Φ900 valve towers with 81 trays, and three cylindrical tube furnaces with a heat load of 1 million kcal / hour. The feed rate of raw material washing oil is 1500kg / h.

[0029] Such as figure 1 As shown, the steam heat exchange between the raw material wash oil and the top naphthalene oil reaches 180°C-200°C and then enters the first rectification tower from the middle. The temperature at the top of the tower is kept at 220°C-222°C. 84% (chromatographic method); the β-methylnaphthalene fraction is extracted from the upper side line (the 12th tray from top to bottom), and the extraction temperature is 237°C-238°C, containing 72% of β-methylnaphthalene , α-methylnaphthalene 6.5%; the temperature at the bottom of the tower is kept at 297°C-298°C. The gas phase pressure at the bottom of the tower is 42KPa.

[0030] The residual oil at the bottom of the first tower and the acenaphthene...

Embodiment 2

[0032] Example 2 The washing oil treatment capacity is 15,000 tons / year

[0033] There are three Φ1000 valve towers with 81 trays, and three cylindrical tube furnaces with a heat load of 1.2 million kcal / hour. The feed rate of raw material washing oil is 2100kg / h.

[0034] The steam heat exchange between the raw material washing oil and the top naphthalene oil reaches 180°C-200°C and then enters the first rectification tower from the middle. Chromatography); the β-methylnaphthalene fraction is extracted from the upper side line (the 12th tray from top to bottom), and the extraction temperature is 237°C-238°C, containing 71% of β-methylnaphthalene, α- Methyl naphthalene 7%; the temperature at the bottom of the tower is kept at 297°C-298°C. The gas phase pressure at the bottom of the tower is 40KPa.

[0035] The residual oil at the bottom of the first tower and the acenaphthene raffinate are mixed at a ratio of 4:1 and then enter the second rectification tower. The temperatur...

Embodiment 3

[0037] Embodiment 3 washing oil treatment capacity 20000 tons / year

[0038] Three float valve towers of Φ1200 have 81 trays, and three cylindrical tube furnaces with a heat load of 1.4 million kcal / hour. The feed rate of raw material washing oil is 2800kg / h.

[0039] The steam heat exchange between the raw material washing oil and the top naphthalene oil reaches 180°C-200°C and then enters the first rectification tower from the middle. Chromatography); the β-methylnaphthalene fraction is extracted from the upper side line (the 12th tray from top to bottom), and the extraction temperature is 237°C-238°C, containing 71% of β-methylnaphthalene, α- Methyl naphthalene 7%; the temperature at the bottom of the tower is kept at 297°C-298°C. The gas phase pressure at the bottom of the tower is 40KPa.

[0040] The residual oil at the bottom of the first tower and the acenaphthene raffinate are mixed at a ratio of 4:1 and then enter the second rectification tower. The temperature at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com