HBPE (hyperbranched polyethylene) functionalized with terminal hydroxyl groups and preparation method thereof

A technology of hyperbranched polyethylene and functionalization, which is applied in the field of hyperbranched polyethylene functionalized with terminal hydroxyl groups and its preparation, can solve the problems of HBPE performance degradation, no practical value, low polymerization activity, etc., and achieve various performances and good practicality Value, high polymerization activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

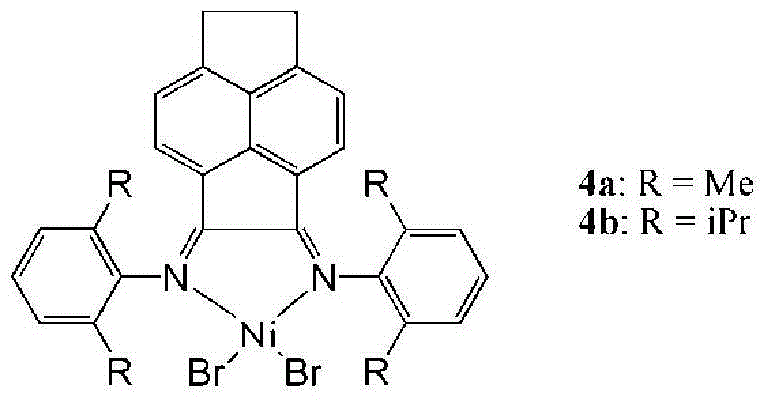

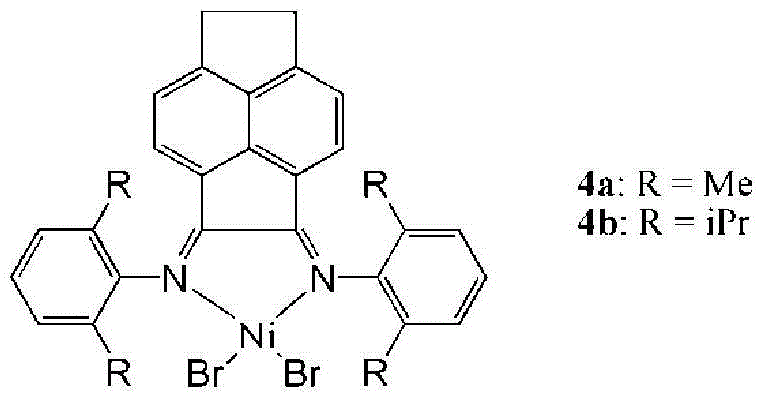

Embodiment 1

[0024] Polymerization of ethylene under normal pressure is carried out under anhydrous and oxygen-free conditions. At 60°C and an ethylene pressure of 0.1 MPa, inject 40 mL of toluene into a 100 mL Schlenk bottle, and then inject 2.0 mmol of diethylaluminum chloride (control the Al / Ni ratio to 200) and 2.0 mmol of diethyl zinc (control Zn / Ni ratio is 200). Dissolve 10 μmol of procatalyst 4b (R is isopropyl) in 10 mL of toluene and inject it. The concentration of 4b in the polymerization system is 100 μmol / L. After half an hour of polymerization, feed oxygen into the polymer solution for oxidation, the reaction time is 2 hours, then reduce and precipitate with acidified ethanol, filter the polymer, wash with methanol or acetone several times, and dry in vacuum at 50°C After reaching a constant weight, 2.10 g of polymer was weighed. The catalyst activity is 0.54×10 6 g[mol(Ni)h] -1 , the number average molecular weight of the polymerization product is 4.5kg / mol, and the poly...

Embodiment 2

[0026] The cocatalyst monochlorodiethylaluminum was replaced by sesquiethylaluminum chloride, and other conditions and polymer treatment methods were the same as in Example 1 to obtain 2.60 grams of polymer. The catalyst activity is 0.67×10 6 g[mol(Ni)h] -1 , the number average molecular weight of the polymerization product is 3.5kg / mol, and the polydispersity coefficient is 1.51. 1 The degree of branching of the polymer was determined to be 125 / 1000 carbon atoms by H-NMR, and the glass transition temperature was -66°C. 93.72% of the polymer chains were terminated with hydroxyl groups.

Embodiment 3

[0028] The cocatalyst monochlorodiethylaluminum was replaced by dichloroethylaluminum, and other conditions and polymer treatment methods were the same as in Example 1 to obtain 2.24 grams of polymer. The catalyst activity is 0.58×10 6 g[mol(Ni)h] -1 , the number average molecular weight of the polymerization product is 4.0kg / mol, and the polydispersity coefficient is 1.53. 1 The degree of branching of the polymer as determined by H-NMR is 117 / 1000 carbon atoms, and the glass transition temperature is -65°C. 91.66% of the polymer chains were terminated with hydroxyl groups.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com