Preparation method and reaction device of acenaphthylene

A technology for the reaction of acenaphthylene, applied in the field of preparation method of acenaphthylene and its reaction device, can solve the problems of high energy consumption, increased separation cost, increased cost of acenaphthylene, etc., to achieve improved conversion rate, reduced preparation cost, and extended life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

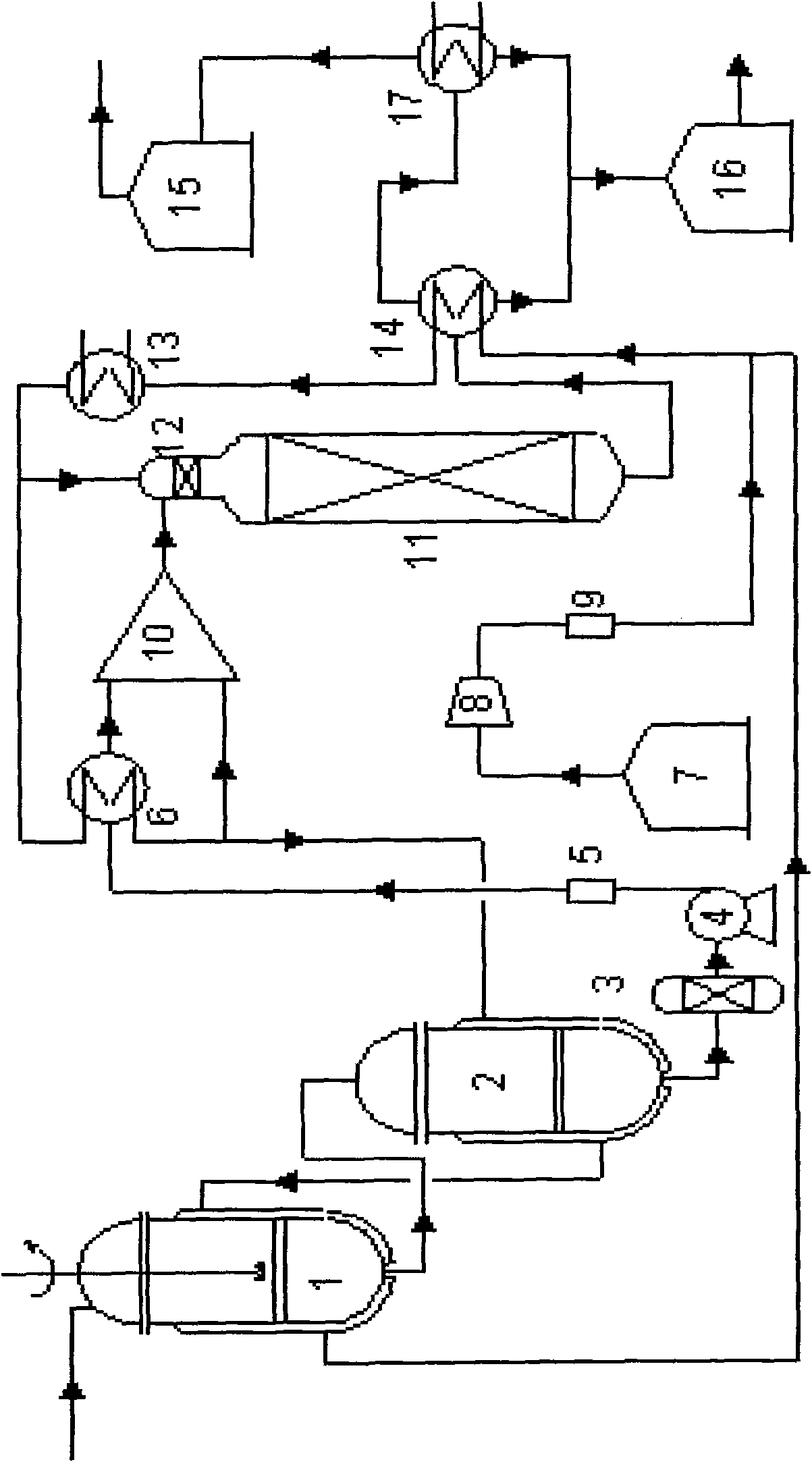

[0046] Example 1. Basic device for preparing acenaphthylene

[0047] figure 1 Shown is the basic device for preparing acenaphthylene of the present invention, which includes:

[0048] A melting chamber 1 with a heating jacket on the outside for melting the raw material solid acenaphthene into liquid acenaphthene;

[0049] A storage tank 2 for storing liquid acenaphthene, the upper part of which is connected to the bottom of the melting chamber 1 through a pipeline, and an insulation jacket is provided on the outside of the storage tank 2;

[0050] A filter 3, connected to the bottom of the storage tank 2 through a pipeline, for filtering liquid acenaphthene;

[0051] A pump 4, connected to the filter 3 through a pipeline, is used to transport the filtered liquid acenaphthene to the vaporization chamber 6;

[0052] A vaporization chamber 6 is used to vaporize the liquid acenaphthene and is connected to the pump 4 through a pipeline. A flow meter 5 can be installed on the pipeline to cont...

Embodiment 2-6

[0065] Example 2-6 Preparation of acenaphthylene

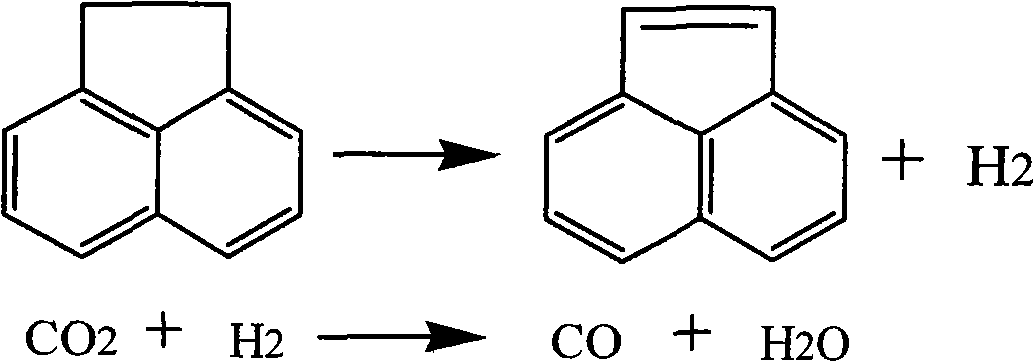

[0066] As shown in Table 1, the raw acenaphthene is first melted in a melter at 90~100℃, and then the liquid space velocity is 0.1~1.0h -1 Pump to the vaporization chamber, vaporize at 290~350℃, then enter the mixing chamber to quickly mix with carbon dioxide at 350~400℃, the molar ratio of carbon dioxide to acenaphthene is 1:1~60:1, and then enter the preheating room for preheating When the temperature reaches 560~700℃, it finally flows into the catalyst bed in the reactor and reacts at 560~700℃ under normal or negative pressure to produce a liquid reaction product containing acenaphthylene. Then ethanol is added to dissolve the acenaphthylene. Acenaphthylene can be obtained by crystallization and drying.

[0067] Table 1

[0068] Example

2

3

4

5

6

Liquid space velocity (h -1 )

0.1

0.3

0.5

0.8

1.0

CO 2 Molar concentration ratio of acenaphthene

1:1

20:1

40:1

60:1

20:1

Pressure(Pa)

1.013×10 5

1.013×10 5

0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com