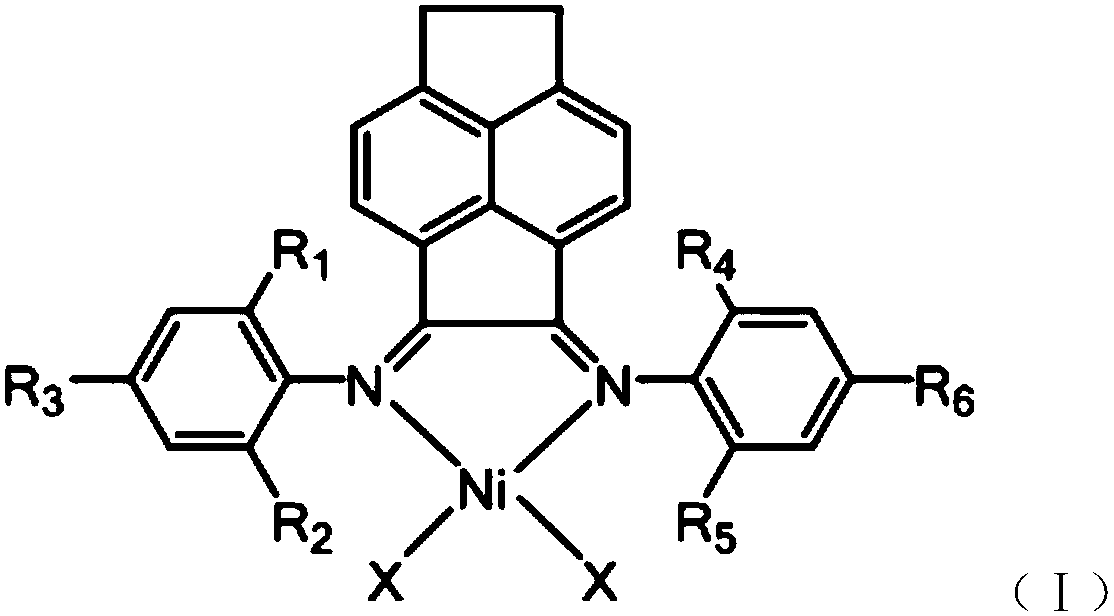

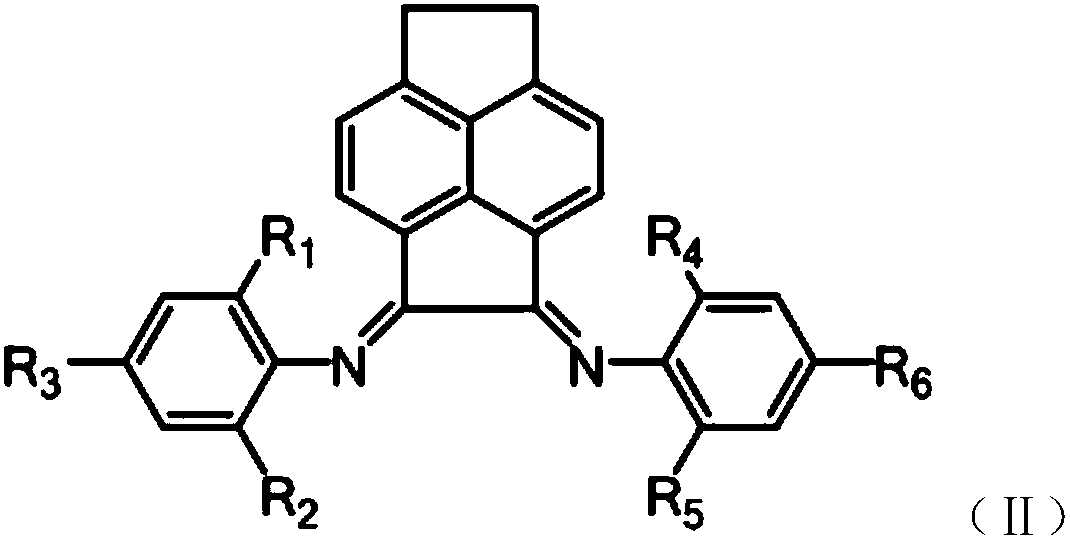

Ethylidene acenaphthene(asymmetric alpha-diimine)nickle catalyst and production method and application thereof

A nickel catalyst and diimine technology, which is applied in the preparation of imino compounds, chemical instruments and methods, nickel organic compounds, etc., can solve the problems of low ligand yield, large steric hindrance, and high cost of catalyst synthesis , to achieve good polymerization activity and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

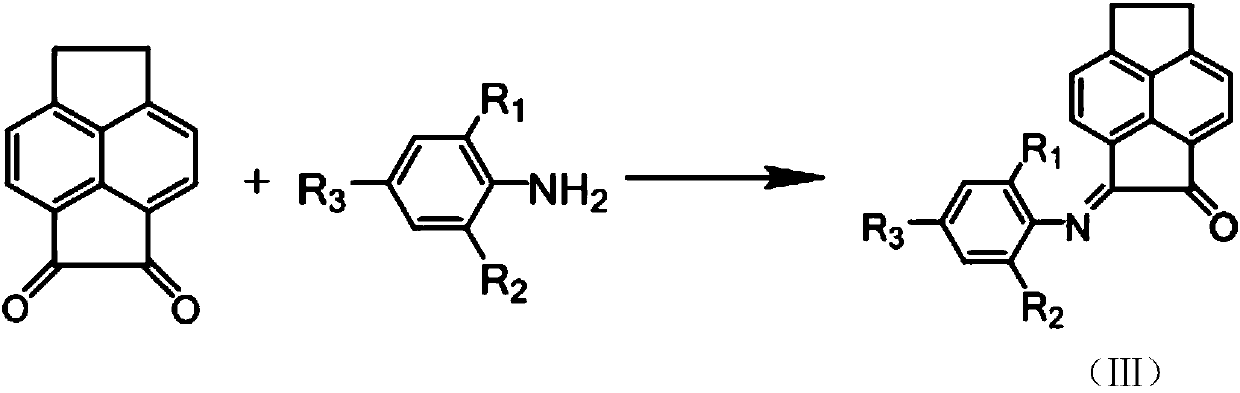

Embodiment 1

[0043] Example 1, Preparation A1: In 2,6-bis(benzhydryl)-4-methylaniline (8.8g, 20mmol) and ethylene acenaphthoquinone (3.7g, 18mmol) in toluene (150mL) solution Add p-toluenesulfonic acid (0.34g, 2mmol) and reflux for 6h. The solvent was removed, and the residue was subjected to silica gel column chromatography with a mixed solvent of dichloromethane and petroleum ether at a volume ratio of 2:1 to obtain A1 with a mass of 4.3 g and a yield of 38%.

Embodiment 2

[0044] Example 2, Preparation A2: In 2,4-bis(benzhydryl)-6-methylaniline (8.8g, 20mmol) and ethylene acenaphthoquinone (3.7g, 18mmol) in toluene (150mL) solution Add p-toluenesulfonic acid (0.34g, 2mmol) and reflux for 6h. The solvent was removed, and the residue was subjected to silica gel column chromatography with a mixed solvent of dichloromethane and petroleum ether at a volume ratio of 2:1 to obtain A2 with a mass of 4.7 g and a yield of 42%.

Embodiment 3

[0045] Example 3, Preparation A3: In 2,6-bis(bis(4-fluorophenyl)methyl)-4-methylaniline (10.2g, 20mmol) and ethylene acenaphthenequinone (3.7g, 18mmol) P-toluenesulfonic acid (0.34 g, 2 mmol) was added to the toluene (150 mL) solution, and the reaction was refluxed for 10 h. The solvent was removed, and the residue was subjected to silica gel column chromatography with a mixed solvent of dichloromethane and petroleum ether at a volume ratio of 2:1 to obtain A3 with a mass of 5.2 g and a yield of 41%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com