Device and method for extracting acenaphthene and acenaphthylene in LCO bicyclic aromatic hydrocarbon

A technology for bicyclic aromatic hydrocarbons and acenaphthylene, which is applied in the field of devices for extracting acenaphthylene and acenaphthylene in LCO bicyclic aromatic hydrocarbons, which can solve the problems of large equipment investment, high production cost, and complicated process, and achieve the effect of reducing production costs and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present invention extracts acenaphthylene and acenaphthylene in LCO bicyclic aromatic hydrocarbons after LCO removes fractions such as dimethylnaphthalene and anthracene, and extracts from remaining fractions mainly acenaphthylene and acenaphthylene and a small amount of dimethylnaphthalene, mainly acenaphthylene and acenaphthylene The alkene content is 96.86%, and the dimethylnaphthalene content is 3.13%.

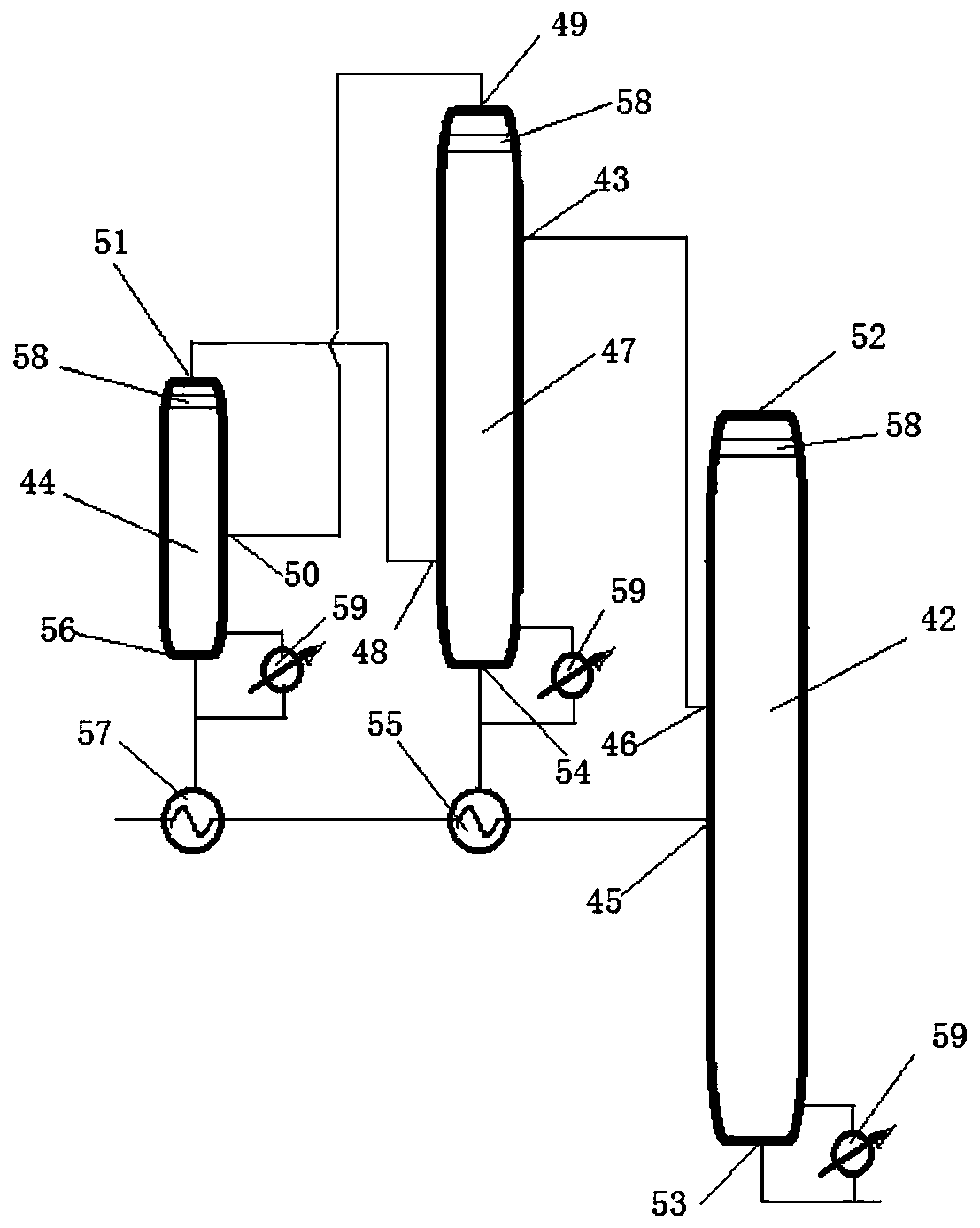

[0040] Among them, the device for removing dimethylnaphthalene and anthracene by LCO is as follows: image 3 As shown, the device for removing dimethylnaphthalene by LCO includes a vacuum sideline rectification tower 42, an extraction tower 43 and a solvent regeneration tower 44 connected in sequence.

[0041] Wherein, the middle and lower end of the vacuum sideline rectification column 42 is provided with a bicyclic aromatic hydrocarbon mixed liquid feed port 45, the middle and upper end is provided with a dimethyl fraction discharge port 46, and the top is pro...

Embodiment 2

[0070] The basic steps are the same as in Example 1. Under the condition that other conditions remain unchanged, the influence of the amount of feed material ① on the content and yield of acenaphthylene and acenaphthylene is studied, and the obtained results Figure 6 shown. It can be seen from the figure that when the amount of feedstock ① is small, the purity is higher, but the yield remains basically unchanged; while when the amount of feedstock is larger, the purity decreases, but the yield increases; however, in the comprehensive purity and yield Under certain conditions, the feed rate of raw materials is 3.6Kg / h.

Embodiment 3

[0072] The basic steps are the same as in Example 1, and under the condition that other conditions are constant, research stirring speed affects the content and yield of acenaphthylene and acenaphthylene, and the obtained results are as follows: Figure 7 shown. It can be seen from this figure that when the stirring speed is small, the purity is low and the yield is high, and when the stirring speed increases, the purity is slightly improved, but the yield is basically unchanged. Comprehensive purity and yield, stirring speed is 550rpm optimal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com