Method, control unit and computer program for controlling milk extraction via an automatic milking machine

A computer program, control unit technology, applied in the field of automatic milking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

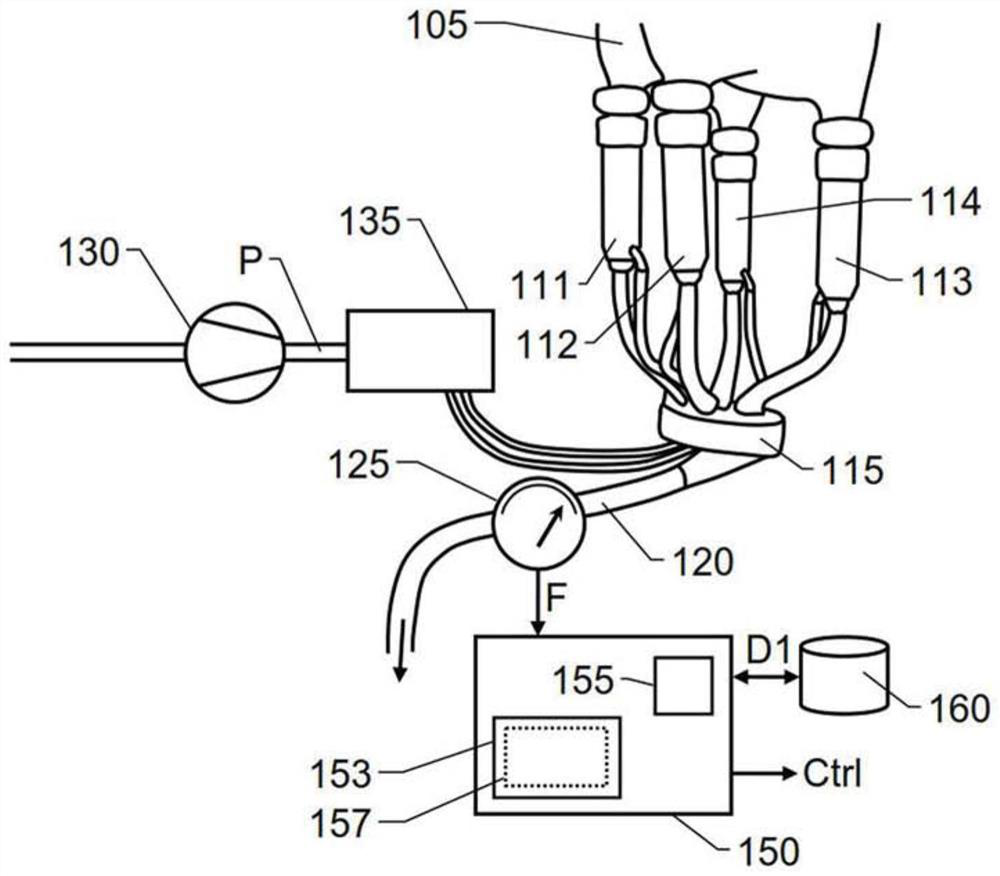

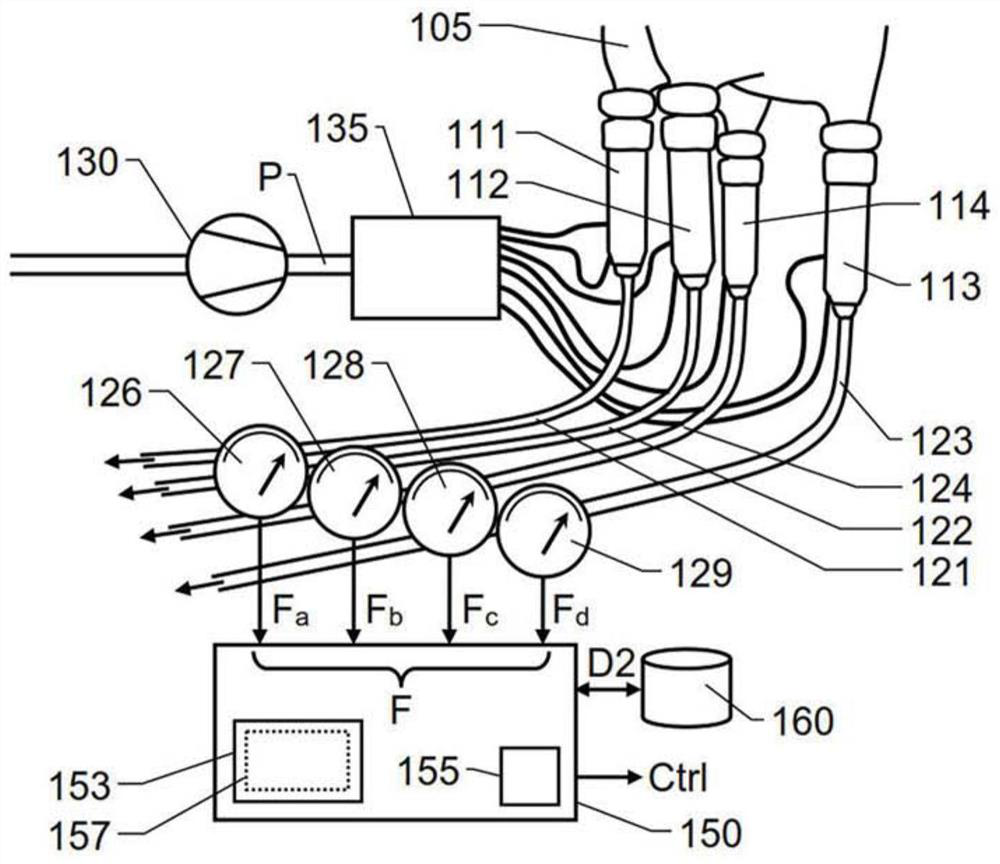

[0032] figure 1 Shown is a milking cluster for udder milking, ie where milk is extracted jointly from all teats of the animal udder 105 based on pressure variations common to all teats. Here, the pulsation controller 135 is arranged to control the pulsating vacuum from the vacuum pump 130 to be repeatedly applied to the pulsation chamber formed between each teatcup and its respective liner therein. The milking claws 115 are connected in a set of four teatcups 111 , 112 , 113 and 114 to the teat receiving cavity by respective milk hoses. Teat cups 111 , 112 , 113 and 114 are in turn attached to respective teats of breast 105 . The pulsation controller 135 is configured to apply a pulsating vacuum to all four teatcups 111 , 112 , 113 and 114 while there is a milking vacuum in the milk hose. Milk is extracted from the udder 105 , drawn by the milking vacuum, collected in the milking claw 115 and forwarded through the milk duct 120 . The flow meter 125 records a parameter repre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com