A plant trough control structure

A technology for controlling structures and plants, applied in botany equipment and methods, soilless cultivation, cultivation, etc., can solve problems such as uncontrollable growth spacing of hydroponic vegetables, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

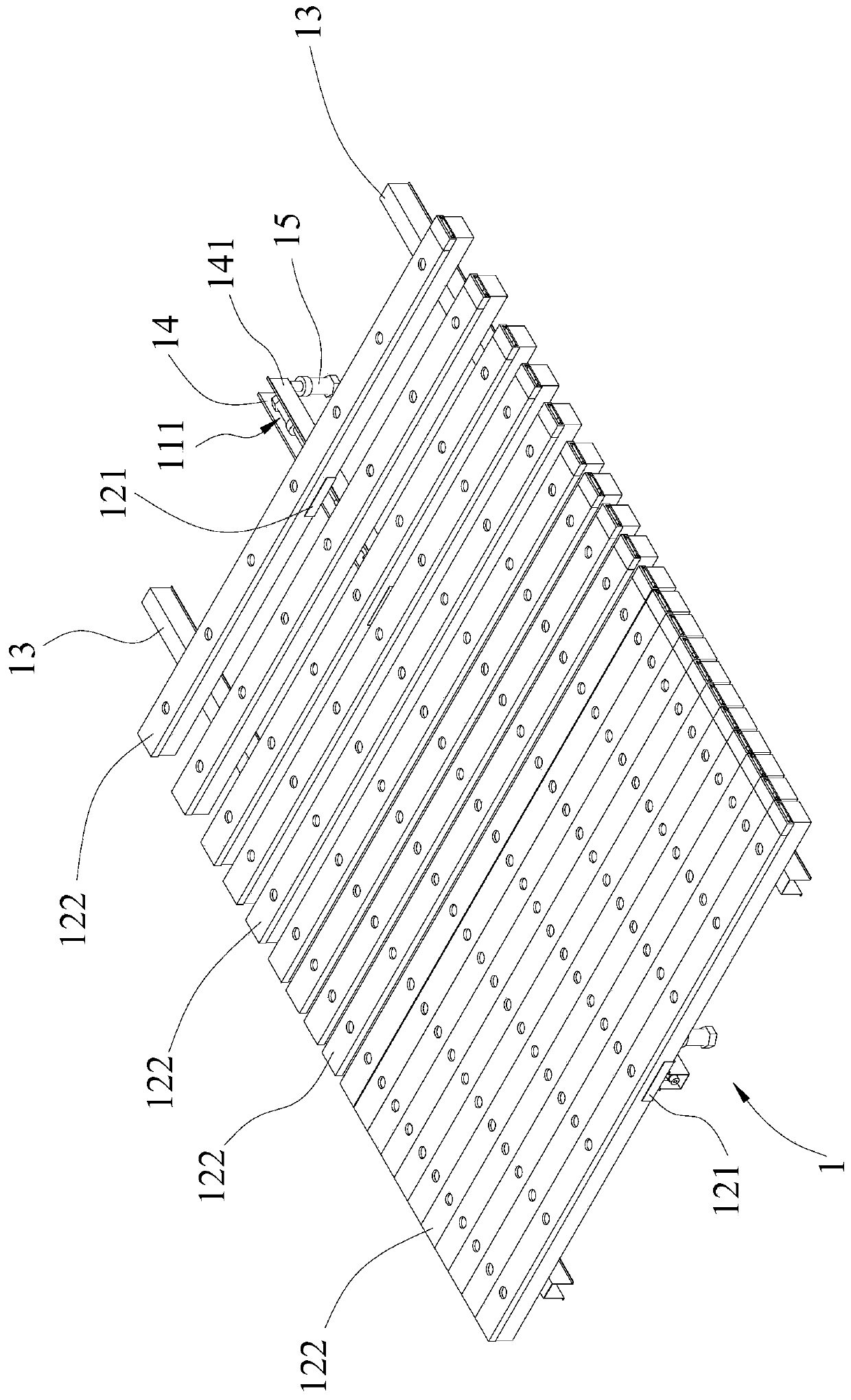

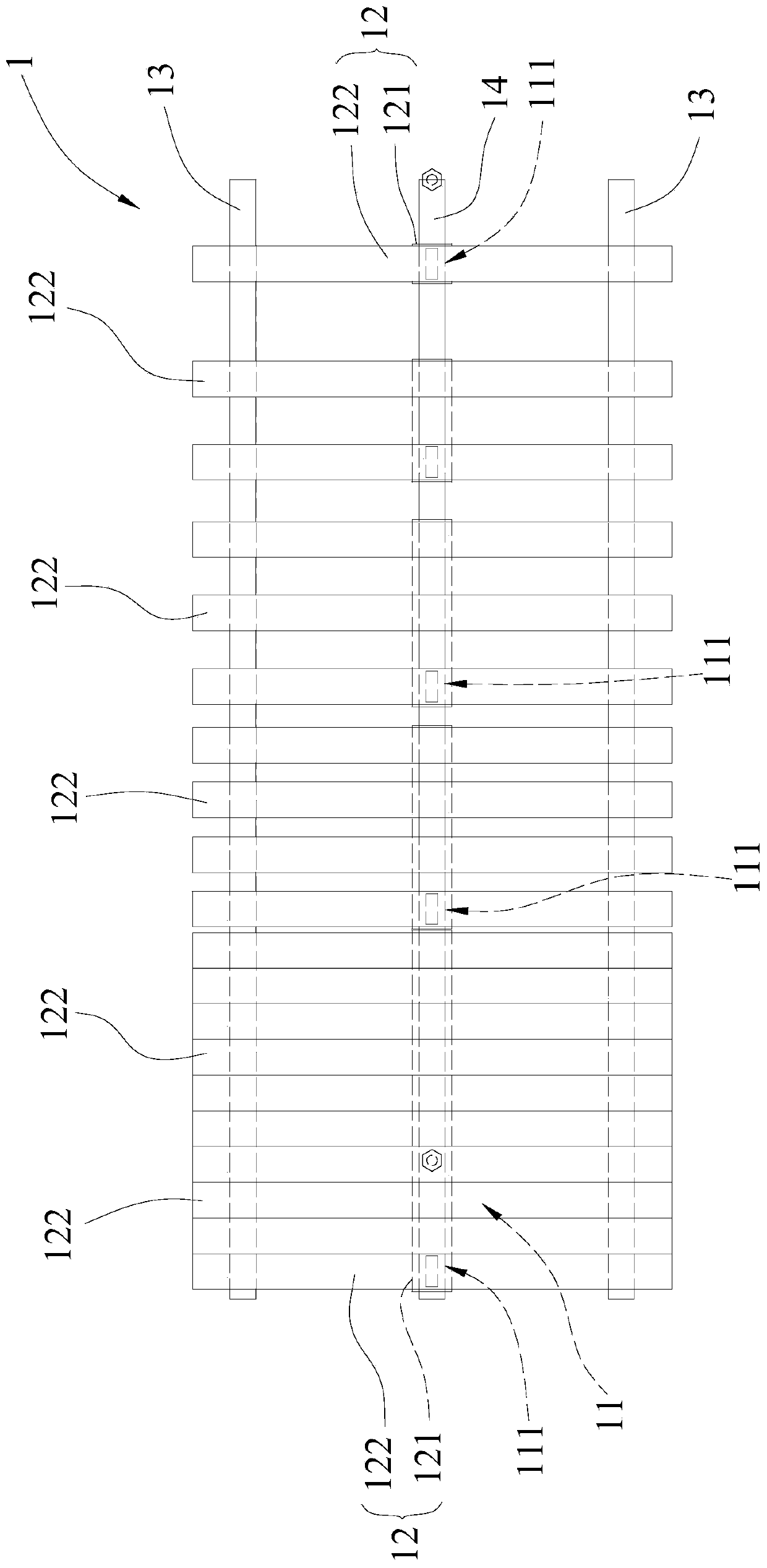

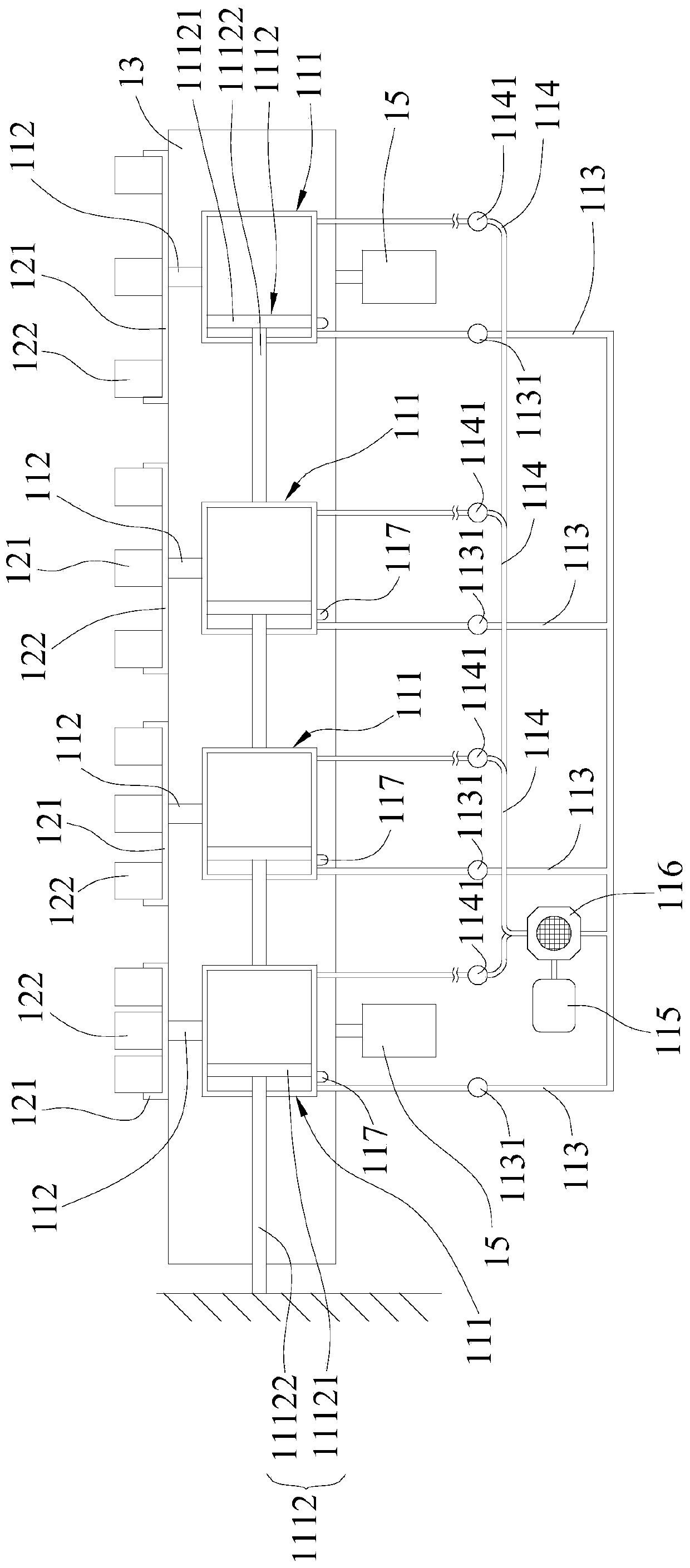

[0076] First, see Figure 1 to Figure 4 As shown, it is the three-dimensional structure diagram, the top view of the overall structure, the side view of the overall structure, and the operation schematic diagram of the lifting assembly of the first embodiment of the plant trough control structure of the present invention, wherein the plant trough control structure 1 of the present invention at least includes: a conveying mechanism 11. It includes a plurality of drive assemblies 111 and a plurality of connecting rods 112. In this embodiment, the drive assembly 111 is a fluid cylinder structure; 111 is respectively provided with a cylinder 1111, a piston rod 1112, and a first pipeline 113 and a second pipeline 114, and one end of each piston rod 1112 is movably arranged inside each cylinder 1111, and the other One end is fixed on the outside of each of the cylinders 1111, and each of the first pipelines 113 and each of the second pipelines 114 are correspondingly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com