Manufacturing method of hard-base soft-structure internal combustion engine connecting rod

A manufacturing method and technology of an internal combustion engine, which are applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problem of excessive fit between the bushing and the inner wall of the small end hole of the connecting rod, unable to meet the processing requirements of the structural connecting rod, and affecting the lining Fatigue life of sleeves and other issues, to achieve the effect of reducing workpiece clamping, machine tool adjustment and workpiece turnover, facilitating mass production and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

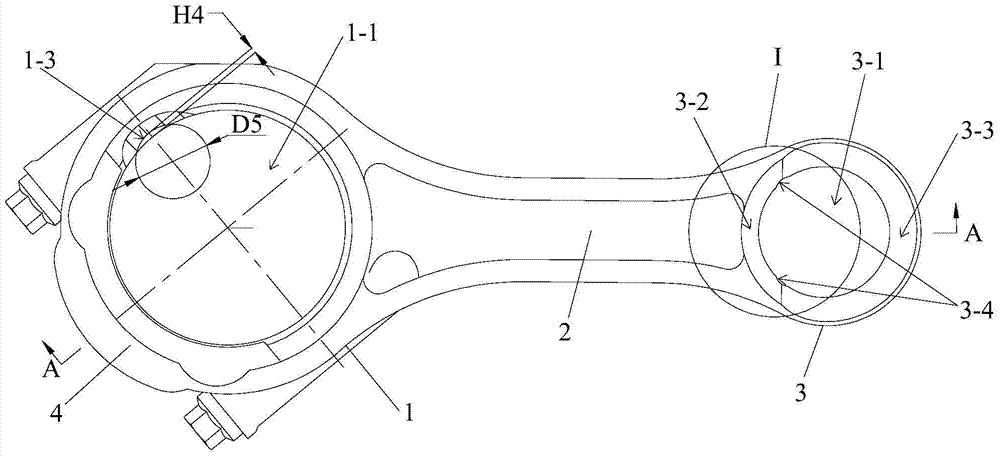

[0048] In this embodiment, a method for manufacturing a connecting rod of a hard base and soft structure internal combustion engine comprises the following steps:

[0049] (1) Blank forging: The alloy structural steel of model 70MnVS is used for blank forging of the connecting rod, and the obtained blank structure is as follows Figure 4 shown;

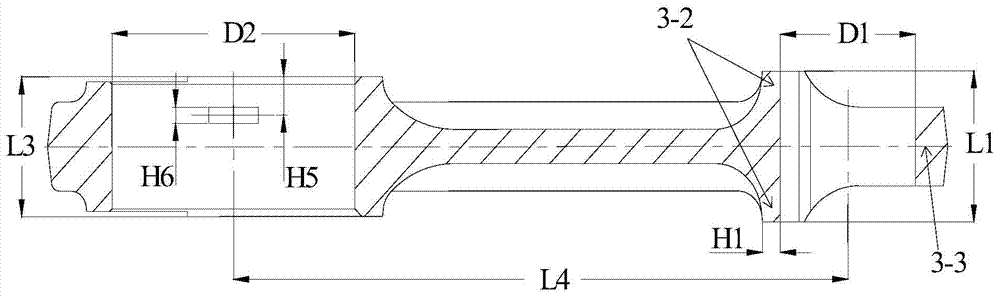

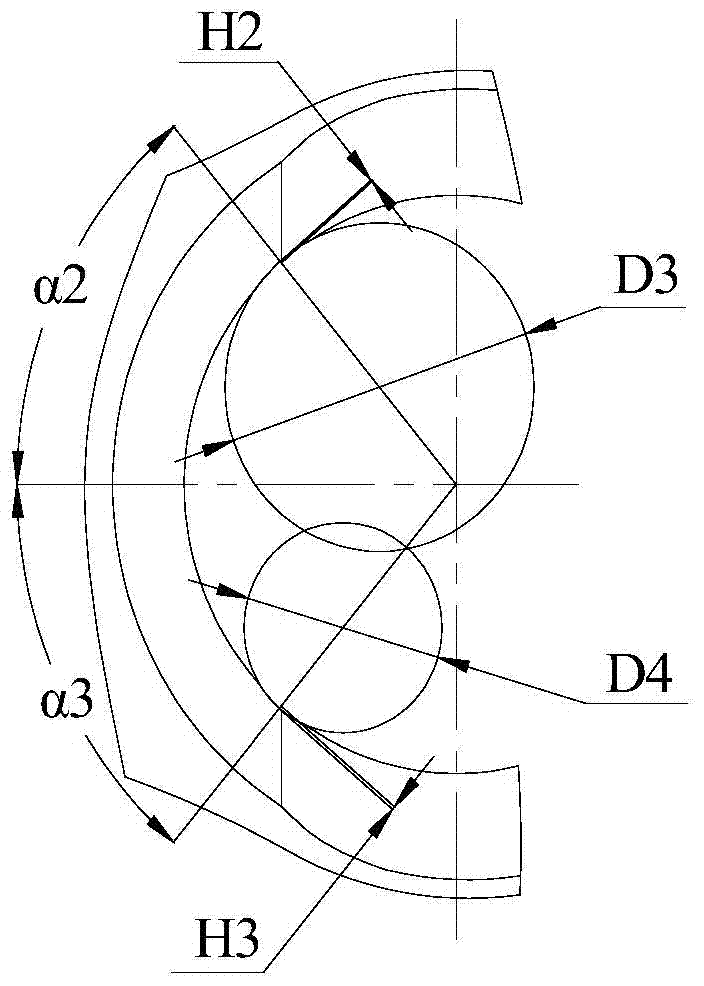

[0050] In this process, the yield strength σ s >550N / mm 2 , the tensile strength σ b 900~1050N / mm 2 The 70MnVS alloy structural steel is used as the hard base material to forge the blank; when forging, the modulus is 0.5mm; if Figure 5 As shown, the dimensions of the small end are: L2=23mm, α1=7°, R1=8mm, R2=15mm, R3=20mm, and the above dimensions are guaranteed in the mold design and forging stages;

[0051] (2) Coarsely grind the end face: Carry out rough grinding on the upper and lower ends of the connecting rod. After the rough grinding is completed, the upper end face of the big end and the upper end face of the small end a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com