Infusion apparatus assembly process

An assembly process and technology for infusion sets, applied in the direction of devices introduced into the body, etc., can solve the problems of time-consuming, labor-intensive, low production efficiency, and high labor costs, and achieve the effects of reducing backlogs of inventory, high production efficiency, and reducing tube winding operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

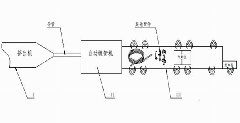

[0010] From figure 1 As can be seen in the figure, an infusion set assembly process includes four steps: catheter extrusion, fitting assembly, leak detection, and packaging.

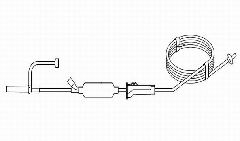

[0011] The catheter of the present invention is directly wound after being extruded and cut by the extruder 1, and shaped with rubber strips, and the catheter remains in a wound state during the assembly of accessories, leak detection, and packaging operations. The accessories assembly is to directly assemble the assembled piercer, dripping funnel, flow regulator, and semi-finished accessories of the liquid medicine filter on the catheter. After leak detection, the catheter is connected to other accessories and is directly packaged and bagged into an infusion set product. Such as figure 2 shown. When packaging, the product accessories are wound into a circle product along the direction of the circle around which the catheter is wound, and then packed into bags.

[0012] Such as figure 1 Shown, extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com